Introduction to Ruida Controller Errors

Having an issue with your laser controller? Are you getting error messages that seem cryptic and confusing? Well look no further as this guide will discuss the most common Ruida controller errors and ways to troubleshoot and fix them.

I have both an OMTech 20”x28” 60W (MF2028-60) and an OMTech 35”x55” 130W (AF3555-130), so I’ve seen my fair share of errors. Some of these errors were self-induced while others were hardware problems. While you may not have either of these exact models, the errors in this guide will still apply to your laser machine if it uses a Ruida controller.

Here are the most common Ruida controller errors, in no particular order:

No Enough Extend Space / Need more overshotting or larger acceleration!

This cryptic message means that the laser head does not have enough room to slow down (decelerate) and stop at the given engraving speed and based on where the design is located.

Potential Solutions

Option 1: The best solution is to move your design away from the edges of the laser in your design software. Once you’ve done this and moved your material on your laser bed to match, this error should go away.

Option 2: Another solution is to slow down the engraving speed. Faster engraving requires more distance past the design for the laser head to slow down, stop, and reverse direction. By slowing down the engraving speed, the laser head will not require as much distance to stop and reverse direction. If you do go this route, keep in mind you’ll likely need to reduce laser power as well.

Frame Slop

This error message means the laser head would travel beyond the bounds of the engraving area. This error usually occurs when the design is outside the edges of the design area.

Potential Solutions

Move the design within the engravable area. If using LightBurn, check to ensure no layers outside of the design area are set to output (they may not be visible but can still have output turned on).

Water Error / Cooler error 1

This error message means the controller thinks your water is not flowing or your chiller is in an error state. Some lasers have a water sensor located inside the machine that verifies water is flowing. Others have an error port where the chiller alarm cable is attached.

Potential Solutions

First, you’ll want to make sure your water is indeed flowing. If you are using a chiller, ensure it is turned on and not in an alarm state. If you are using a water pump, ensure it is on and that water is flowing.

Second, double check all water fittings and ensure there are no leaks. Also, if your chiller alarm cable is connected to your laser (only some lasers have this feature), ensure that cable is connected correctly.

If you find any issues as stated above, fix the issue and then escape the error by pressing the “Esc” key on the controller and try to run your file again. If the error still persists, you may have an air bubble affecting the water flow sensor or the water flow sensor may need to be replaced. If you are comfortable working with electronics, you can check the two connectors on the water flow sensor with a multimeter. These connections should be “open” when water is not flowing and “closed” when water is flowing.

Lastly, you can disable the water flow protection. Warning: only perform this step at your own risk. Water is required to keep your laser tube cool and functioning properly. Disabling the water flow protection means no protection for your laser if you run it without the chiller or water pump turned on. In Lightburn, click on Edit > Machine Settings. Scroll down to “Vendor Settings” and click the down arrow. Change the “Water Protect Enabled, Laser 1” from “True” to “False”. Click “Write”.

Note that your settings might look different depending on your laser.

Machine Protected / Open cover protection

This error message means the controller thinks your door is open.

Potential Solutions

First, ensure the door is closed and pushed all the way down until it seats properly. If this does not fix the issue, it is possible that the door sensor needs to be adjusted or replaced.

To troubleshoot, follow these steps:

Hold up a piece of metal near the sensor (usually located on the right hand side of the machine where the door meets the machine body and is orange in color). You should see a small light turn red at the back of the sensor. If this works, then slightly adjust the sensor outwards using a wrench until it is close enough to sense the door without hitting it. If the red light does not illuminate when holding a piece of metal to the sensor, then check all wiring to ensure it is intact. If there is no wiring damage, you should replace the sensor.

It is also possible to disable this alarm in the controller settings (via the controller or Lightburn). Warning: perform this step at your own risk. The door sensor ensures your laser does NOT fire with the door open. This is for safety reasons and should not be disabled unless you accept the risk. In Lightburn, click on Edit > Machine Settings. Scroll down to “Vendor Settings” and click the down arrow. Change the “Enable Door Open Protect” from “True” to “False”. Click “Write”.

Note that your settings might look different depending on your laser.

Conclusion

While it is possible to have other errors on your controller, these are by far the most common. Following the simple troubleshooting and solutions provided should get you back to using your laser in no time. If you encounter any other Ruida error code not mentioned here, please post it in the OMTech Forum. A laser specialist will reply to your post with possible solutions in the next few days.

Author Bio

Patrick S.

When the COVID-19 pandemic hit in early 2020, my kids (9, 7, and 4 at that time) and I found we had a ton of extra time on our hands. Instead of spending this time on screens, I decided we should learn a new skill. While I’ve always done some woodworking mainly for our own use, we purchased a small CNC diode laser and learned how to use that. We gave away many items and eventually had people asking us to make them custom things, so we started asking them to pay. From this, our «accidental side business» was born. We ended up purchasing an OMTech laser to aid in our ability to engrave and cut wood at speed. Today, we have a CNC wood router, a small diode laser, an OMTech 60W 20″x28″ laser machine, and an OMTech 130W 35”x55” laser machine.

If you’d like to check out some of the awesome things we’ve been able to make with our laser, check out or Facebook page: https://www.facebook.com/sticksandstoneswrkshop

ходил сегодня вокруг него весь день, решил разобрать и узнать что это за приблуда на выходе воды, помогла эта статья

http://www.yusto.ru/articles/lazernoe-oborudovanie/883-water-alarm/

снял свой разобрал от сих до сих, там простой пласмассовый флажок с пружиной на противовесе которого маленький магнитик, поток воды перемещает флажок и он в свою очередь этот магнитик, но я представления не имею как он просто колыхаясь через стенку может перемкнуть какие то контакты, очень слабенький и маленький, еле лип к металлу. Первое что я заподозрил это то что он некачественно сделан, те контактики что должен перемыкать магнитик залиты в цельный корпус их не посмотрел, второе возможно он должен на входе стоять а не на выходе там куда больше напор, потому как я получил его он был уже собран, вероятно там перепутали. собрал поставил, эти 2 провода что в него входят перемкнул теперь работает, но думаю что нужно все таки что менять, вода постоянно под наблюдением смотрю чтоб циркулировалась , чиллер пока не приобрел.

здесь вы можете задать свои вопросы и узнать ответы на наиболее часто встречающиеся проблемы

Наиболее популярные ошибки лазерных станков

Ошибка чиллера ER06

Если у вас возникла проблема или появились вопросы по работе оборудования вы всегда можете связаться с нами в группе ВК, WhatsApp или в Телеграмм. Общайтесь со службой технической поддержки в любимых мессенджерах.

▪ Почему выбирают нас ▪

У нас купили более 600 станков

Cookie-файлы

Настройка cookie-файлов

Детальная информация о целях обработки данных и поставщиках, которые мы используем на наших сайтах

Аналитические Cookie-файлы

Отключить все

Мы используем файлы Cookie для улучшения работы, персонализации и повышения удобства пользования нашим сайтом. Продолжая посещать сайт, вы соглашаетесь на использование нами файлов Cookie.

Подробнее о нашей политике в отношении Cookie.

Подробнее

Понятно

Moderators: HPC, Daven

-

Trevor Wootton

- Posts: 23

- Joined: Sat May 22, 2010 2:59 pm

- Contact:

Water Chiller & Error 5

Hello, at the end of Feb. 2014 i bought a chiller for my 6840. Changed all the water pipes/tubes, bought from HPC, cleaned the water flow sensor, and used new de-ionised water. E05 came up on the chillers display. messed around abit checking for water flow, kinks in the pipes, air bubbles etc. I rang HPC and Chris kindly sent me a maual, it doesn’t give error codes. After switching the chiller off and on at various times it appeared to work OK. Since then the chiller comes up with E05 every so often. I pause the job switch the chiller off and on and continue. Today however it error came up staright away and I can’t get it to go away. The jobs I’ve done are engraving wooden boxes and cutting paper. Have been told the water sensor i have can cause poor water flow.

Any ideas pleeeaaasssseee

Trevor ![]()

-

Spooky

- Posts: 1291

- Joined: Mon Apr 26, 2010 10:17 pm

- Contact:

Re: Water Chiller & Error 5

Post

by Spooky » Tue Apr 01, 2014 2:33 pm

What chiller model Trev?

cheers

Dave

Please note I am not employed by HPC, any advice or recomendations I give are based on my own experience and are not necessarily the same as HPC’s. First point of contact on any hardware issues should be with HPC

Dave@OpticalPower.co.uk

-

Trevor Wootton

- Posts: 23

- Joined: Sat May 22, 2010 2:59 pm

-

Contact:

Re: Water Chiller & Error 5

Post

by Trevor Wootton » Tue Apr 01, 2014 4:36 pm

Hi,

Firstly sorry for my spelling mistakes on the previous post. Hit submit instead of preview. The cooler is a PH LW04-06-BLP.

After posting my problem, I decided to change the water although it hasn’t done a great deal of work. Before I had the chiller i have been using the laser machine for 4years, changing the water every few months, blown a tube and had a few water related problems. Since I’ve had the chiller everything has inproved, power and speed and general performance, BUT i’m suprised i’ve had to change the water so soon.

At least i’m up and running but not 100% happy. Do HPC sell an water additive. I’ve read the forums with referance to adding Milton and the various results.

Any pointers would be helpful.

Trev

-

Spooky

- Posts: 1291

- Joined: Mon Apr 26, 2010 10:17 pm

- Contact:

Re: Water Chiller & Error 5

Post

by Spooky » Wed Apr 02, 2014 2:06 am

Hiya Trev,

Go with HPC Lasercool additive, works really well at keeping down fungus and algae, (its also an excellent anti freeze) it’s surprising how much mucky water affects performance, I change mine using distilled every 3 months (it only holds 5 litres)

It’s amazing just how fast algae can propagate in a high radiation area like a tube!

I’ll get get a readout for error code 5 and post it ![]()

cheers

Dave

Please note I am not employed by HPC, any advice or recomendations I give are based on my own experience and are not necessarily the same as HPC’s. First point of contact on any hardware issues should be with HPC

Dave@OpticalPower.co.uk

Who is online

Users browsing this forum: No registered users and 8 guests

Вопросы-Ответы

Почему код ошибки E1 на охладителе водяного охлаждения лазера который охлаждает машину маркировки лазера пакета еды?

опубликованный:

2021-01-04

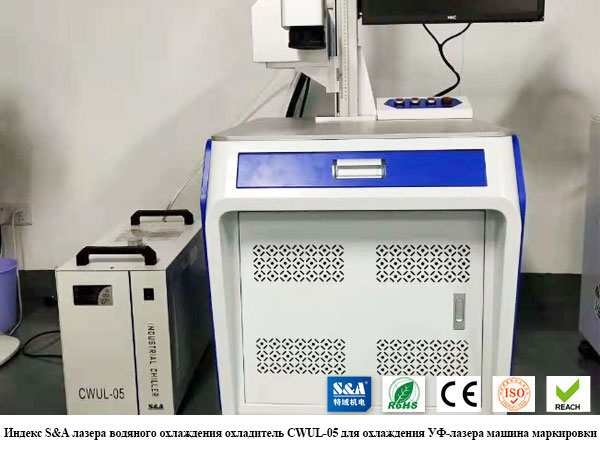

Если код ошибки E1 возникает в машине лазерной маркировки упаковки пищевых продуктов лазерный охладитель водяного охлаждения, это означает, что срабатывает сигнализация сверхвысокой комнатной температуры. В этом случае предлагается поставить лазерный охладитель водяного охлаждения в том месте, где есть хорошая подача воздуха и ниже 40 градусов С. Это может не только помочь устранить тревогу, но и повысить эффективность охлаждения УФ-лазерного охладителя воды.

После 18-летнего развития, мы устанавливаем неукоснительную систему качества продукции и обеспечиваем устоявшееся послепродажное обслуживание. Мы предлагаем более 90 стандартных моделей водяных чиллеров и 120 моделей водяных чиллеров для индивидуальной настройки. С охлаждая емкостью колебаясь от 0.6 KW к 30KW, наши охладители воды применимы для того чтобы охладить различные источники лазера,машины лазера обрабатывая, машины CNC, медицинские инструменты, лабораторное оборудование и так далее.