Operation

The table gives an overview of possible

displays. In the «Comment» column you will

find information on how to proceed should any

of these messages be displayed.

Message text/

Error code

OVERHEATING

A5022

ACCELERATOR

A3002

A3003

A3004

A3005

A3006

A3007

A3505

ACCELERATOR

A3008

ACCELERATOR

A3811

BRAKE SENSOR

A3016

A3017

BRAKE SENSOR

A3035

CONFIGURATION

A2111

CONFIGURATION

A3801

CONFIGURATION

A3812

Comment

Traction motor(s) is/are too hot.

1st phase: regulation of acceleration and speed.

2nd phase: limitation of phase current in converter (emer-

gency driving function is retained).

The error automatically disappears as soon as the tempera-

ture is below the limit.

If the error occurs frequently, notify your authorised service

centre.

Sensor fault, truck cannot be driven.

Notify your authorised service centre.

Accelerator voltages (for dual pedal) do not match; truck

cannot be driven.

Notify your authorised service centre.

Accelerator configuration is invalid; truck cannot be driven.

Notify your authorised service centre.

Sensor fault; truck can only be driven at emergency mode

speed.

Notify your authorised service centre.

Brake fluid level too low or switch defective; truck can only

be driven at the emergency mode speed.

Notify your authorised service centre.

Parameterisation error or defective printed circuit board;

drive unit and hydraulic drive not functioning.

Notify your authorised service centre.

Parameterisation error; drive unit and hydraulic drive not

functioning.

Notify your authorised service centre.

Drive program parameters are outside the permitted range.

The drive program parameters are limited internally.

Notify your authorised service centre.

57348011825 EN — 12/2015

5

Display messages

237

Коды ошибок спецтехники

Оказываем услуги по диагностике спецтехники, с определением и подробным описанием кодов ошибок, составлением диагностической карты и дальнейшим ремонтом.

Диагностика кодов ошибок

Если у вас на спецтехнике загорелась лампа неисправности чек энжин (Check Engine) и появились какие-то сбои в работе техники, могут сбои не появиться совсем или проявляться периодически. Но в любом случае при обращении в нашу компанию, наш автоэлектрик-диагност проведет электронное обследование причины появления ошибки, расшифрует коды, напишет рекомендации и предложит устранение обнаруженной неисправности. Считываем и производим диагностику коды ошибок с дальнейшим устранением на следующих моделях спецтехники:

Модельный ряд

Здравствуйте! На электропогрузчике Yole ERP20VF LWW появилась ошибка 12820 не могли б Вы подсказать, что за ошибка? Спасибо!

какой двигатель стоит? марка

Здравствуйте! На электропогрузчике марка STILL R 2020 2004г появилась ошибка 198 на табло не могли б Вы подсказать, что за ошибка? Спасибо!

LuiGong clg 888 погрузчик, скажите пожалуйста через 200 метров выскакивает на табло 89и ключ, после этого задняя не включается. Скажите пожалуйста описание ошибки.

Здравствуйте код ошибки D0422 bobkat TL-470, что означает эта ошибка.

Нужен сканер для дорожной спец техники!

Здравствуйте на погрузчике чтз ПК 30 выскакивает 35 и ключ но Погрузчик работает в чем причина не подскажите

Здравствуйте на асфальтоукладчике volvo p7820c выскочила ошибка code 13001 и не выдвигает я плита, не могли ли подсказать в чём причина

На погрузчике xcmg LW 500FM не горит панель приборов, в чем может быть причина можете подсказать? Появилась после прикурки акумулятора.

Здравствуйте на электропогрузчике MANITOU ME 320 вылезла ошибка 114 что делать?

На бульдозер komatsu d155ax-6 вылезли ошибки»E 03 DFAFKA, E 04 2302 LH, E 02 DDTSLH, E 03 CA 1632″помогите пожалуйста.

Здравствуйте такая проблема airman pdw500 сварочный генератор не выдаёт напряжение встает в защиту загорается ошибка е06 не могу найти не где расшифровку ошибок на него что можете подсказать.

Здравствуйте на погрузчике загорелись ошибки

IN-14 EESAV ERORRE L

IN-15 EEERA ERORRE H

В чем причина?

Добрый день. Подскажите плиз, код ошибки 002164.9 на холланде б115б, что означает?

Steering Wheel Position

Здравствуйте. У меня на экскаваторе jcb 160 выбивает на бортовой системе 118 HYD PMP ПОДСКАЖИТЕ ПОЖАЛУЙСТА ЧТО ДЕЛАТЬ.

Добрый день на конусной дробилке выдаёт ошибку c0003 и мигают кнопки interlock в чем может быть причина за ранее спасибо

Здравствуйте. На эксковаторе фиат кобелко выбило ошибку 29 ченж оил. Стоит ивековский мотор. Что это значит

Подскажите пожалуйста, экскаватор Case WX200, код ошибки fault 001 и fault 019,что делать?

Салам алейкум кто знает на фронтальной пагрузчике ашибка C200F

Здравствуйте у меня на катке hamm на грунтовом выскакивает ошибка er9 что это означает и как её устроить подскажите пожалуйста…

Ошибка связи с педалью акселератора. Есть и другая инфа, а также запчасти и сервис YALE.

На погрузчике nissan выдаёт ошибку F-34 не подскажите что это такое?

смотрите топливные фильтра. как ведет себя техника?

Скажите а по какой причине загорается датчик стоп и идёт отсчёт на погрузчике case sr 220

Здравствуйте! Terex tlb 840 пишет:

Errors

6049.07

SPN. FMI

Подскажите пожалуйста что это значит.

Добрый день. На автопогрузчике Doosan BR14JW на экране появляется F2 что это за ошибка?

Каток HAMM 90 выдает ошибку 016, подскажите, что означает, найти нигде не могу

Здравствуйте подскажите пожалуйста на болансировочной машинеNordnerg 4523c ошибка error 6 как её устронить и что значет?

На погрузчике Yale GDP30TK появилась ошибка err CO30, не подскажете что за неполадки??

нужно проводить диагностику неисправности. вызывайте нас, приедем. уточните только какой двигатель стоит

подскажите пожалуйста выдает ошибку 33 что э то

Здравствуйте. Техника какая?

Каток HAMM HD+120 Высвечивается ошибка S_97 и F_3

нужно проводить диагностику неисправности. вызывайте нас, приедем. уточните только какой двигатель стоит

Здравствуйте на погруссике volvo L350F вадаёт ошипку PSVD1-11 ПОДСКАЖИТЕ

как устранить ошибку Е301 на комбайне NEW HOLLAND сs 6090

только одним способом. приглашаете нашего специалиста, приезжаем, диагностируем, выявляем проблему. если проблема в электрике — устраняем.

Каток Bomag 217d, ошибка 8981,что означает?

Здравствуйте. У меня такой вопрос. Спецтехника кейс максум мх140 не работает передний скорость. Сингнал и в прибор скоросте мегает книга

каток hamm ошибка 21

EMERGENCY STOP solenoid (NOT-STOP) orfront vibration solenoidShort-circuit, line rupture

Добрый день, на электропогрузчике NICHIYU FB18 высветилась ошибка D33, не подскажите что это?

Добрый день. Какая серия погрузчика?

Здравствуйте. Эта ошибка связанна с неисправностью трансмиссии. Более подробно, об этой ошибке информацию можно определить, только через диагностический интерфейс

Здравствуйте. Причин по которой возникает эта ошибка, может быть много. Это может быть связанно с питанием, так-же проблемы могут быть в КАН. Не исключена так-же неисправность самих блоков управления. Проверьте предохранители. Для более конкретного ответа, нужна диагностика неисправности.

нужна таблица кодов неисправности каток ХАММ 3412 двигатель ДОЙЦ, как можно заполучить. На данный момент интересуют такие коды как: 253 212 228 зарание спасибо

Здравствуйте! По кодам ошибок Deutz:

212 — повышенное давление в топливной рампе

228 — недостоверный сигнал блока управления

253 код ошибки отсутствует, есть 235 — внутренняя ошибка блока управления

Код 253 — The pressure relief valve (PRV) has reached the number of allowed activations (Клапан сброса давления (PRV) достиг количества разрешенных активаций)

Вот вопрос, как эти коды сбросить?

Здравствуйте. Если это активная ошибка, ее нужно сначала устранить, затем она перейдет в сохраненные (историю). Сохраненные ошибки сбрасываются с помощью диагностического оборудования или по истечению определенного времени — сами. Коды ошибок нужны для помощи в поиске неисправности, в случае с активными ошибками нужно искать причину. В вашем случае, предполагаю, по каким-то причинам электроника пытается сбросить давление и включает клапан, он или не срабатывает по электрическим или механическим причинам. Необходимо эти причины найти и устранить.

Погрузчик тойота газ бензин заводская установка двигатель 4y ecs. Нет выхода для диагностики. Горит ошибка E c4-5. Работает только на газе. На бензине только стартер вращается.

Здравствуйте подскажите пожалуйста на катке Hamm 3520. Ошибка 90 в чем проблема. Заранее спасибо.

Здравствуйте кму unic 344 код ошибки 73 скажите что это

Здраствуйте на тероксе 995 погрузчик экскаватор выдал ошибку 6048,07 и не заводится

Здравствуйте. По указанному коду нет никакой информации. Вы верно указали код? Можем сделать диагностику и определить неисправность

Трактор terrion код ошибки т-85?

Здравствуйте. В данный момент нет возможности оперативно ответить на ваш вопрос. Постараюсь в ближайшее время вытащить коды ошибок трактора Террион из диагностической программы и расшифровать код неисправности.

Добрый день. Подскажите расшифровку кодов ошибок ALARM ON MOD1/0 и MOD8/1

Здравствуйте. На какой технике появились эти ошибки?

Здравствуйте. На катке HAMM 3412 при включении зажигания на индикаторах (скорость, обороты и частота) загораются символы 03 03 03. Потом они гаснут. Что это может быть?

Здравствуйте. Скорее всего это коды самопроверки. А в работе катка нет никаких проблем?

Через 3 минуты после запуска он глохнет

Надо проводить диагностику неисправности и выявлять причину, а по этим символам никакой информации дать не могу. Только с выездом на место сможем определить причину.

Проверь косу под воздушным фильтром, там есть 3 места где коса перетирается. И фишка которая идет с этой косы на косу двигателя(там возможно переломились провода)…

kfge20d погрузчик мицубиси

код ошибки F36

подскажите пожалуйста

Здравствуйте. Далгат, к сожалению, по кодам ошибок мы Вам помочь не сможем. Необходимо подключать соответствующий диагностический сканер и смотреть.

Здравствуйте у меня на экскаватора MM 30SR, отказались работать джойстики, скажите есть ли возможность сбросить ошибки, отключение АКБ не помогает.

Здравствуйте. У Вас текущая активная ошибка. Нужно искать причину неисправности и устранять ее. Только после этого восстановиться работа джойстика. Где территориально находится техника?

На атокране LIEBHERR LTM 1050-3.1 — ЕКТ на дисплее пишет ошибку — 170, подскажите пожалуйста в чем проблема

Здравствуйте Александр подскажите пожалуйста Маниту 10180 выскакивает ошибка А: 536

Здравствуйте. По Маниту у нас пока нет распечатанных мануалов. Описание ошибок активируется только при подключении диагностического сканера к системе.

Расшифруйте код ошибки er 42 на экскаватор Вольво

Александр, Добрый день. Есть погрузчик Locust L-903. Yanmar 4TN98-ZNWI, 2013 г. в.

С недавнего времени при прогретом двигателе начинают плавать обороты и двигатель не развивает обороты, ни на холодную ни на горячую. Под нагрузкой из трубы валит черный дым в очень большом количестве.

Еще из признаков, мне непонятных, в фильтре отстойнике почернело топливо. Похоже и в баке такая же ситуация.

Встроенная система диагностики выдает ошибку 1-3 (одно длинное свечение и три моргания лампы сервиса)

Топливо точно нормальное, только газпромнефть.

Из проделанных работ: чистка клапана егр, регулировка клапанов, регулировка давления в топливной системе. На форсунках до регулировки было давление — 240. Отрегулировали до 210. ТНВД не трогали.

Проблема в том, что до нас на нем кто-то делал капиталку. Замена колец, сальников и т. д.

Изначально была оторвана коса проводов на клапан егр. Восстановили, почистили, ошибка ушла. Обороты стали набираться отлично, тяга была на высоте, протестировали большими кучами снега и отдали. Но через месяц ситуация повторилась и усугубилась. Сейчас также нет тяги и дымит черным, при прогретом двигателе плавают обороты. Помогите, пожалуйста, если не сложно мыслью или советом. Мы вам точно конкурентами не будем, территориально находимся в Тюменской области.

На катке Bomag bw 216d появляется ошибка 5140, 5100 и глохнет двигатель. Подскажите пожалуйста с чем это может быть связано

Здравствуйте. В любом случае нужно делать полную диагностику неисправности. Причины могут быть как механические, так и связанные с электрикой, электроникой.

День добрый, грунтовый каток AMMANN ASC 170, ошибка SPN 105 FMI 16. Пишет INTAKE MAN1 AIR TEMP HIGH.

Здравствуйте. Неисправность отражается на работе катка? Для точного выяснения причины необходима диагностика. Возможна техника работает в аварийном режиме

Подскажите не работает электронная педаль газа в кабине libherr 1050-3.1 поменяли новую. прописали, ни кого эффекта. где может неисправность?

Здравствуйте. Эта неисправность не из-за педали газа. Ответ на ваш вопрос можно дать только после проведения диагностики. Причин этой неисправности может быть много

Здравствуйте, подскажите, пожалуйста, расшифровку кода ошибки E 46 на погрузчике Митсубиси FB16NT 2006 года в. Спасибо!

DOOSAN DX300LCA Код ошибки 7.0. Подскажите пожалуйста что означает?

Здравствуйте. Для выяснение причины необходимо провести диагностику, в распечатке такой ошибки нет

Здравствуйте. Ошибка 05 — неисправность программирования системы, более подробной информации в мануалах нет. Для точного ответа нужно проводить диагностику

Александр, добрый день. На вилочном погрузчике caterpiller DP18NT загорается код ошибки F16 и при этом моргает лампочка температуры масла двигателя. подскажите расшифровку кода ошибки, и возможные неисправности.

Заранее благодарю.

Александр, добрый вечер у меня jungheinrich 2011 года. На табло выскакивает ERR 0802 после 0304 не могли бы вы подсказать в чём причина поломки. Заранее спасибо.

Здравствуйте. По данной технике описание ошибок специализируется, только после подключения диагностического интерфейса. Отдельного описания кодов ошибок нет.

Здравствуйте. Подскажите Электропогрузчик коматсу VO15M230 не едет ни вперед ни назад. На схеме светодиод выдает ошибку 13 или31. С чего начать искать.

Здравствуйте. Устранение любой неисправности начинается с диагностики. Нужно провести диагностику и после выявления — устранить.

Здравствуйте. Так ошибка 13 и 31 дайте пожалуйста расшифровку этих ошибок

Срочно подскажите пожалуста. На эксковаторе JCB 220.выбивает ошибку ENGP1093.если можете подскажите

Здравствуйте. Нужно проводить диагностику неисправности. Файл интерактивной проверки идеализируется только после подключения и ввода кода дилера.

Срочно подскажите пожалуста. На экскаваторе liebherr 914.выбивает ошибку E 006,E 013,E443.если можете подскажите

Здравствуйте. Отправим в личку.

Здравствуйте! Не могу на форум написать!! выручайте! ВИлочный электропогрузчик ТОЙОТА 7fb10 горит ошибка С2-3 и демо режим. как выйти из него и что за ошибка?? Уже голову сломали весь погрузчик облазили

Здравствуйте. Отправим информацию в личку

Добрый день. На минипогрузчике мустанг 2066 двигатель yanmar 4tnv98-znms горит чек 1 длинный 3 коротких Помогите продиагностировать. Техника находится в ростовской области (согласен на платную консультацию). Спасибо

На вилочном электропогрузчике caterpillar ep16cpnt горит ошибка #A9. Все работает но не дает скорости больше 5 км в час. Что это может быть?

Здравствуйте! подскажите что означает код ошибки SE2301-07? на гусеничном экскаваторе volvo EC250D?

Здравствуйте. Экскаватор-погрузчик CASE выдает коды ошибок: 65588, 65590. Что эти ошибки означают.

Здравствуйте. Чтобы ответить на вопрос — нужно проводить диагностику, свободных мануалов с расшифровкой кодов нет

Здравствуйте выходит ошибка на электропогрузчике Dalian

Alarm 37 on node 2 подскажите пожалуйста что может быть

Здравствуйте ошибка hyster RS45-31CH

Не переключаются передачи

Единственная ошибка e_con

Здравствуйте.

Миниэкскаватор мицубиси (CAT) выдает ошибку r05 при этом отключается рукоять подскажите пожалуйста где проблема заранее спасибо

Здравствуйте. Причин может быть много — дистанционно трудно понять. Нужно проводить диагностику на месте.

Современный вилочный электропогрузчик Still RX 20-15

Транспорт Still RX 20-16 оборудован двухмоторным передним приводом, напряжение которого составляет 48 В. Конструкция техники предусматривает питание от аккумуляторов и замену аккумуляторных батарей.

Электропогрузчик Still RX 20-16 имеет следующие габариты:

Технические данные модификации RX 20-16:

Электрический погрузчик Still RX 20-20 используется для перемещения грузов на территории складских помещений и вагонов. Питание систем осуществляется через аккумуляторные батареи.

Технические показатели и параметры модели RX 20-20:

| Наибольшая масса поднимаемого груза | 2000 кг |

| Вес агрегата | 3453 кг |

| Мощность двигателей | 4,5 л. с. |

| Максимальная скорость движения | 16 км/ч |

| Клиренс | 123 мм |

| Габариты | 2918*1138*2160 мм |

| Центр тяжести | 500 мм |

| Свободная высота | 150 мм |

| Емкость аккумуляторов | 700 А*ч |

| Размер шин | 200/50-10 |

| Общее количество колес | 4 |

| Число ведущих колесных механизмов | 2 |

| Колея передних колес | 942 мм |

| Колея задних колес | 865 мм |

| Внешний габаритный радиус поворота | 1883 мм |

| Скорость работы | 380 мм/с |

Немецкая компания STILL GmbH основана в Гамбурге в 1920 году как небольшой цех по производству и ремонту электродвигателей и автоматических устройств подачи электроэнергии при перебоях в сети. Затем диапазон производимой продукции расширялся и до начала войны это был уже известный в Германии машиностроительный завод, специализирующийся на электротехнических изделиях.

После окончания Второй мировой войны завод отстроили и перепрофилировали на производство складского оборудования и погрузочной техники. Первый дизельный погрузчик Still вышел из ворот фирмы в 1949 году и с тех пор Still остается одной из авторитетнейших компаний, специализирующейся на производстве вилочных погрузчиков.

Расширяя и модифицируя производство и укрупняя мощности, в 1989 году компания купила фирму SAXBY (САКСБИ) а в 1997 году – Wagner (Вагнер). В начале 2000-х фирма вышла за пределы Германии в плане производства и открыла завод в Южной Америке, став, таким образом, производителем межконтинентального класса.

В настоящее время вилочные погрузчики Still производятся на немецких заводах в Гамбурге и Ройтлингене, во Франции и Южной Америке. Немецкие и французские заводы ориентированы на рынки европейских и азиатских стран, а южноамериканские – на США, Канаду и всю Южную Америку.

Более 10 000 единиц техники различных лет выпуска работают в странах бывшего СССР, большая часть их находится в России. Их отличительной особенностью являются очень длительный срок работоспособности и постоянная адаптация новых конструкций и модификаций к условиям эксплуатации в каждом конкретном случае.

Погрузчики вилочные Still включают модели электропогрузчиков и автопогрузчиков с дизельными и бензиново-газовыми двигателями грузоподъёмностью от 1 до 8 тонн, электротягачи, высотные штабелеры – ричтраки. Среди выпускаемой продукции взрывозащищенные погрузчики, высотные штабелеры с возможностью трехсторонней обработки груза, действующие в узких коридорах и проходах. Любые виды работ по транспортировке и перевалке грузов различного типа по плечу технике с маркой Still.

Дизельные и бензиновые погрузчики вилочного типа Still

Среди всех моделей вилочных погрузчиков дизельные машины занимают наиболее заметное место. Они отличаются мощностью двигателей, возможностью работать в любых климатических условиях и отработанностью конструкции. Все функции, которые включены в базовый перечень возможностей, необходимы для качественной работы на производстве или складах.

Дизельный вилочный погрузчик Still RX 70 16 принадлежит к моделям серии RX, оборудованных двигателями VW на машинах грузоподъемностью до 5 тонн, Deutz или TCD на более мощных машинах грузоподъемностью от 5 до 8 тонн или моторами BXT. Все модели моторов отличаются продуманностью конструкции и оптимальным соотношением мощности и расхода горючего.

Погрузчик вилочный Still RX 70-16 характеризуется следующими базовыми характеристиками:

Радиус разворота по внешнему периметру составляет 1926 мм, грузоподъемность 1,6 тонны при скорости подъема груза 0,59 м/с, и высота подъема груза – 3,8 метра. Мощный двигатель и автоматическая трансмиссия позволяет погрузчику разгонятся до скорости 27 км/час. Погрузчики оборудуются шинами из эластика.

Погрузчики этой серии оснащены программой Blue-Q, основное предназначение которой – экономия энергии. Режима Blue-Q включается простым нажатием клавиши. В этом режиме работы экономия энергоресурсов составляет до 10%. Применение интеллектуальной оптимизации главных характеристик работы дает возможность экономить энергию тогда, когда это не уменьшает производительность машины.

Дизельный Still RX70 35 и RX70 30 являются гибридными моделями. Они разработаны на базе погрузчиков серии RX 70 и позволяют сократить расход топлива до 15%. Данная техника характеризуется низким уровнем выброса углекислого и угарного газов, что обеспечивает соблюдение самых строгих экологических норм.

Гибридные погрузчики имеют возможность использовать энергию, сгенерированную при торможении из кинетической энергии движения. Она сохраняется и в дальнейшем используется для ускорения. Погрузчики оборудованы топливными баками и батареей конденсаторов Ultra-Caps, заряжаемой энергией, выработанной процессе торможения. Связующим звеном служит инвертор, управляющий зарядом батареи. Эти машины очень экологичные, производительны, маневренны и компактны.

Пониженный уровень выбросов выхлопных газов позволяет использовать их в закрытых производственных помещениях только с естественной вентиляцией. Даже в холодные периоды, когда температура окружающего воздуха намного ниже 0, погрузчики этой серии работают в запрограммированном цикле экономии энергии.

В серию RX входят модели:

Они отличаются грузоподъемностью и мощностью установленных двигателей, но общие принципы построения конструкции ходовой системы и подъемного механизма базируются на единой концепции.

Погрузчики вилочные Штиль серии R тоже представлены несколькими моделями различной грузоподъемности. Одной из наиболее характерных моделей этой серии является Still R 75 45 с грузоподъемностью 4500 кг и высотой подъема груза до 3300 мм. Главным образом он используется для работ на открытом пространстве. Но благодаря небольшому для такой мощной машины радиусу разворота, может эффективно работать и в помещениях не очень большой площади и в узких проходах складов.

Погрузчики Штиль с электродвигателями

Компания STILL производит электропогрузчики, в ходовой конструкции которых 3 или 4 опоры. На погрузчиках с четырьмя опорами установлено по паре передних и задних колес. Трехопорные электрические вилочные погрузчики Still оснащаются сдвоенными передними и одинарными задними колесами. В линейке STILL машины как с передними так и с задними приводными колесами. Заднеприводные погрузчики применяются для грузов, массой не более полутора тонн. Транспортировка и подъем более тяжелых грузов производится с помощью переднеприводной техники.

Электропогрузчики представляют собой машины для складских работ. Их навесное оборудование работает от тяговой аккумуляторной батареи. Аккумуляторные батареи для электропогрузчиков расположены очень низко, что служит дополнительным функционалом сохранения равновесия. Предельная высота подъема вилочного электрического погрузчика Still составляет 7920 мм, скорость движения по ровной поверхности – от 16 до 20 км/ч с грузом. Грузоподъемность данного типа оборудования лежит в пределах от1000 до 5100 кг.

Аккумуляторный вилочный погрузчик Still RX 20-20 является одним из наиболее востребованных для работ в помещениях, грузовых отсеках вагонов и автомобилей. Пригоден для эксплуатации в подсобных помещениях больших торговых центров и на рынках.

Электропогрузчики Still серии RX 20 – современные мощные погрузчики с двухмоторным приводом на передние колеса напряжением 48В. Впервые в погрузчике внедрена практическая возможность замены аккумулятора сбоку. Сменную батарею можно установить без применения кран балки. Высокая степень надежности машины обусловлена использованием двух CAN-BUS шин и двух независимых процессоров.

Сменная батарея устанавливается сбоку погрузчика с помощью обыкновенной паллетной грузовой тележки – рохли или специальной установки для ускоренной замены батареи. Низкое расположение передней части погрузчика и боковая панель управления открывают наилучший передний обзор вил и груза. Защитная крыша оператора к шасси крепится эластично, что уменьшает воздействия шума и вибрации.

Период межтехнического обслуживания составляет 1 раз в год или 1000 часов, что является очень высоким показателем даже для техники такого уровня, как электрические вилочные погрузчики Still. Теплоотвод от электрооборудования осуществляется благодаря креплению этих модулей на массиве противовеса. Вентиляторы охлаждения агрегатов и фильтры не применяются.

Как электрические, так и дизельные погрузчики Still востребованы в тех отраслях производства и торговли, где требуется долговременная и надежная работа машин и механизмов. Цена этих машин окупается их эффективностью.

Дизельные

Вилочный погрузчик Still RX 70-30 оборудован дизельным двигателем модели VW BXT. Транспорт отличается пониженным уровнем расхода топливной жидкости и гидравлическими механическими стояночными тормозами.

Характеристики модели RX 70-30:

| Грузоподъемность | 3000 кг |

| Полная масса | 4235 кг |

| Количество цилиндрических элементов | 4 |

| Мощность силового агрегата | 38 л. с. |

| Транспортная скорость | 21 км/ч |

| Дорожный просвет | 125 мм |

| Колесная база | 1700 мм |

| Габариты | 3705*1180*2175 мм |

| Допустимый наклон мачты | 10° |

| Центр тяжести | 0,5 м |

| Свободная высота | 160 мм |

| Длина мачты | 3800 мм |

| Колесная формула | 2*2 |

| Внешний габаритный радиус поворота | 2387 мм |

| Скорость подъема груза | 470 мм/с |

| Скорость опускания груза | 600 мм/с |

| Давление в гидравлической системе | 250 бар |

Дизельный погрузчик Штиль RC 40-30 с дизельным двигателем отличается простотой эксплуатации. Техническое обслуживание транспорта нужно проводить только через 500 отработанных моточасов.

Параметры модификации RC 40-30:

Особенности электрических погрузчиков Still, LemaZowell и Combilift

Отправить эту страницу:

реализует в Великом Новгороде вилочные электрические погрузчики и другие виды технических средств известных производителей складской техники. Мы также предлагаем оригинальные запчасти и оказываем широкий спектр услуг по ремонту и сервисному обслуживанию. Все работы проводятся согласно установленному регламенту и рекомендациям изготовителей строительного и складского оборудования. Качество поставляемой техники и запасных частей подтверждено сопроводительной документацией.

В нашем каталоге электрические погрузчики представлены продукцией ТМ Still LemaZowell и Combilift. Они различаются высотой подъема, грузоподъемностью и особенностями конструкции. Технические характеристики электропогрузчиков определяют максимально допустимую нагрузку, интенсивность работы и условия использования. Нарушения правил эксплуатации могут привести к различным повреждениям техники.

Виды и назначение погрузчиков LemaZowell

Электропогрузчики LemaZowell включают модели на трех — и четырехколесных опорах. Техника первого типа позволяет поднимать поддоны с грузом весом от 1600 до 2000 кг, и рассчитана на средний уровень нагрузок. Высота подъема вил зависит от модели и может составлять от 3 до 6 м. Источником питания служит аккумуляторная батарея. Погрузчики LemaZowell, оснащенные четырьмя колесными опорами, предназначены для подъема грузов на поддонах весом от 1000 до 3500 кг.

К преимуществам вилочных погрузчиков LemaZowell относятся:

Конструкция оборудования предусматривает эффективное распределение мощности, благодаря которому можно увеличить время работы в режиме энергосбережения до 10%.

Особенности и характеристики погрузчиков Still

Электрокары ТМ Still также представлены трехопорными и четырехопорными моделями, грузоподъемность которых варьируется от 1000 кг у RX 50-10 до 4990 кг у RX 60-50. Высота подъема вил определяется модификацией техники. Серия RX 50 включает очень компактные погрузчики ТМ Still, которые позволяют обрабатывать грузы весом 1000-1600 кг, и могут работать в условиях ограниченного пространства. Они востребованы на складах и предприятиях разных отраслей промышленности с небольшим грузооборотом.

При значительной нагрузке целесообразно купить погрузчик серии RX 60, который отличается высокой производительностью и экономным потреблением энергии. Благодаря Li-Ion аккумуляторам его можно использовать при работе в трехсменном режиме без применения запасной батареи. Высокая скорость передвижения снижает время обработки грузов и дает возможность увеличить грузопоток без привлечения другой техники.

Среди преимуществ электрических погрузчиков Still можно выделить:

Они также отличаются высокой маневренностью и практически отсутствием шума при передвижении, подъеме и спуске грузов на паллетах.

Конструктивные особенности узкопроходных погрузчиков Combilift

Уникальность погрузчиков Aisle-Master от производителя Combilift заключается в особенности конструкции машины, в которых передняя часть с кареткой вил и задняя часть с сиденьем оператора шарнирно-сочленены между собой и не имеют жесткой сцепки. Это позволяет обрабатывать грузы в узких межстеллажных проходов шириной всего от 1,6 м.

При этом погрузчик позволяет осуществлять три способа штабелирования: направо, прямо, налево — за счет поворота грузовых вил перпендикулярно кабине водителя.

Основными преимуществами погрузчиков Aisle-Master являются:

Где купить электрические погрузчики в Новгороде

предлагает большой выбор моделей погрузчиков и предоставляет гарантии на оборудование. Мы реализуем в Великом Новгороде новые и б/у погрузчики электрические, штабелеры, тележки и другие виды грузоподъемной техники, качество которых подтверждено сертификатами. Сотрудничество с крупными производителями позволяет нам поставлять оборудование в короткие сроки и оперативно выполнять заказы любой сложности.

Вы можете выбрать и купить электрические погрузчики в нашем Каталоге. При возникновении вопросов — добавьте интересующие модели в корзину и оформите заявку, мы свяжемся с Вами и поможем с выбором.

Неисправности и ремонт

Неисправности автопогрузчика могут быть вызваны низким зарядом аккумуляторной батареи, недостаточным уровнем давления в системе гидравлического трансформатора, загрязнением предохранительного клапана, изношенными механизмами и т. д.

Ремонт погрузчиков Still нужно проводить при отключенном силовом агрегате и с использованием специальных инструментов.

Сначала нужно провести внешний осмотр вышедшего из строя узла. После этого можно приступать к разбору системы и замене износившихся деталей. Если причиной поломки стал недостаточный уровень топливной или масляной жидкости, необходимо просто долить ее до требуемой отметки.

Погрузчик Still RX 70 Гибрид 3.0 и 3.5 т.

Still создало первый в своем роде вилочный погрузчик с функцией возврата потраченной и передачи энергии RX 70 Hybrid (Гибрид). Этот погрузчик может быть одновременно мощным и экономичным, благодаря аккумуляции двух энергосистем. Одна система получает энергию от топливного двигателя, а другая система в свою очередь получает энергию из энергонакопителей и конденсаторов модификации UltraCaps. RX 70 обладает специфическими конденсаторами, имеющими два слоя, которые могут с легкостью аккумулировать энергию, например образующуюся при торможении.

Вилочный погрузчик Still RX 70 Гибрид 3.0 и 3.5 т.

Электропогрузчик RX 70 может с легкостью высвободить энергопотенциал, накопленный при помощи функции рекуперации (возврата потраченной энергии). Это стало возможным при использовании новейшего двигателя внутреннего сгорания погрузчика и самого процесса возврата энергии. Гибрид собрал в себе не только новые технологии, но и перенял старые положительные характеристики машин Still. RX 70 возвел новую планку в конструировании вилочных погрузчиков. Гибрид отличается от своих предшественников не только экономичностью, но и молоизнашиваемыми механизмами.

Что касается производительности погрузчика Still RX 70 Hybrid, то она осталась на прежнем очень высоком уровне, это стало возможным за счет экономичности в показателях потребления топлива до 0,8 л за 1 моточас. Гибрид улучшил показатели экономии перед своими предшественниками на 20 %. Сокращение потребления топлива всегда сопровождается сокращением выбросов в атмосферу углекислого газа и других вредных веществ, что делает Гибрид более экологически чистым.

Гибридный двигатель RX 70 имеет меньшее количество оборотов, поэтому его детали меньше изнашиваются и данная модель производит меньше шума.

При передвижении погрузчика кинетическая энергия преобразуется в электрическую, которая накапливается в конденсаторах и передается на модульный блок, где установлены мощные энергоаккумуляторы. Далее накопленная энергия быстро передается системе погрузчика, тем самым увеличивая показатель энергопотенциала машины. Сам модульный блок настолько компактен, что с легкостью вписался в конструкцию вилочного погрузчика. RX 70 Hybrid очень хорошо справляется с погрузкой/разгрузкой грузов. Погрузчик постоянно сменяет динамику движения с торможения на ускорение и обратно, что в свою очередь позволяет еще больше рекуперировать энергию.

Возврат энергии начинается уже при первых оборотах двигателя погрузчика RX 70 Hybrid. Буквально каждое движение погрузчика способно рекуперировать энергию.

В условиях нашего нестабильного рынка топлива погрузчик RX 70 Hybrid отлично подходит для работы на складе. Гибридная система Still еще раз доказывает то, что такой погрузчик незаменим и показывает максимальные результаты производительности при оптимальном использовании ресурсов.

RX 70 Гибрид максимально быстро окупит Ваши затраты и поможет сэкономить ресурсы.

Характеристики RX 70-30 Гибрид и RX 70-35 Гибрид:

Цены и условия приобретения вилочного погрузчика Вы можете узнать у официальных дилеров Still.

Источники:

https://auto-elektric. ru/kompyuternaya-diagnostika-gruzovyh-avtomobiley/oshst711/

https://foksevmash. ru/servis/pogruzchik-vilochnyj-shtil. html

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Original instructions

Electric pallet truck

EXU-S 22

EXU-S 24

0177 0178

50018043464 EN — 10/2017

Related Manuals for Still EXU-S 22

Summary of Contents for Still EXU-S 22

-

Page 1

Original instructions Electric pallet truck EXU-S 22 EXU-S 24 0177 0178 50018043464 EN — 10/2017… -

Page 3

• Information on transport, initial commis- sioning and storage of industrial trucks Internet address and QR code The information can be accessed at any time by pasting the address https://m.still.de/vdma in a web browser or by scanning the QR code. 50018043464 EN — 10/2017… -

Page 5: Table Of Contents

Table of contents Introduction Forklift data …………2 General information .

-

Page 6

Table of contents Overview Technical description ……….22 Overviews . -

Page 7

Table of contents Check of brake and presence area ……..51 Checking the emergency brake button . -

Page 8

VDI data sheet for standard EXU-S 22 …….. -

Page 9: Introduction

Introduction…

-

Page 10: Forklift Data

Introduction Forklift data Forklift data We recommend that you record the principal forklift data in the following table so that they are available if required by the sales network or authorised service centre. Type Serial number Date of delivery General information •…

-

Page 11

Introduction How to Consult the Manual CAUTION ENVIRONMENT NOTE Failure to observe the instructions highlighted with Failure to observe the instructions highlighted this symbol may cause damage to the forklift and, with this symbol may cause environmental in some cases, result in warranty invalidity. damage. -

Page 12: Date Of Edition And Latest Update Of This Manual

Introduction Date of edition and latest update of this manual Date of edition and latest update of this manual The publication date of these operating instructions is printed on the cover sheet. The manufacturer makes continuous efforts to improve its industrial trucks, and therefore reserves the right to implement changes and to accept no claims concerning the information provided in this manual.

-

Page 13: Ce Labelling

Introduction CE labelling CE labelling The manufacturer uses CE labelling to indi- cate that the truck complies with the standards and regulations valid at the time of marketing. This is confirmed by the issued EC declaration of conformity. The CE labelling is attached to the nameplate.

-

Page 14: Ec Declaration Of Conformity In Accordance With Machinery Directive

Introduction EC declaration of conformity in accordance with Machinery Directive EC declaration of conformity in accordance with Machinery Di- rective Declaration STILL GmbH Berzeliusstraße 10 D-22113 Hamburg Germany We declare that the according to these operating instructions Industrial truck according to these operating instructions Model conforms to the latest version of the Machinery Directive 2006/42/EC.

-

Page 15: Technical Service And Spare Parts

Introduction Technical service and spare parts Technical service and spare parts For scheduled maintenance and any repairs to the technical characteristics of the forklift over the forklift, contact only the authorised service time. network. Only original spare parts provided by the man- The authorised service network has personnel ufacturer may be used for forklift maintenance trained by the manufacturer, original spare…

-

Page 16: Modifications To Forklift

Introduction Modifications to Forklift Do not use beyond the limits of the climatic use precautions are necessary. Contact the conditions indicated below: authorised sales network for more informa- tion. • Maximum ambient temperature: +40°C • Minimum ambient temperature: +5°C DANGER •…

-

Page 17: Environmental Considerations

Introduction Environmental considerations Environmental considerations Disposal of components and batteries The truck is composed of different materials. If components or batteries need to be replaced and disposed of, they must be: • disposed of, • treated or • recycled in accordance with regional and national regulations.

-

Page 18: Packaging

Introduction Environmental considerations Packaging During delivery of the truck, certain parts are packaged to provide protection during transport. This packaging must be removed completely prior to initial start-up. ENVIRONMENT NOTE The packaging material must be disposed of properly after delivery of the truck. 50018043464 EN — 10/2017…

-

Page 19: Safety

Safety…

-

Page 20: Safety Guidelines

Safety Safety guidelines Safety guidelines General Precautions regulations integrate those in the manual NOTE «Rules for approved use of industrial vehicles». Some safety regulations to be followed when using the forklift are listed below. These General Safety Rules • Only allow qualified, trained and authorized •…

-

Page 21: Battery Connection Cables

Safety Safety guidelines CAUTION Passing over cracks or damaged parts of the floor with the truck is prohibited. Dirt and any objects in the work path must be removed immediately. Battery connection cables CAUTION Using sockets with NON-ORIGINAL battery con- nection cables can be dangerous (see purchase references in the parts catalogue) Requirements for the traction-battery…

-

Page 22: Safety Regulations Relative To Operating Materials

Safety Safety guidelines Safety Regulations Relative to Operating Materials Rules for handling and disposing of Oils operating materials • Do not allow to come into contact with the skin. ENVIRONMENT NOTE • Do not inhale oil vapors. Improper use and disposal of operating and •…

-

Page 23: Residual Risks

Safety Residual risks and disposal of the life-expired battery must NOTE be carried out as required by law. We advise For greater information, consult the specific you to contact the authorised service network battery manual that comes with the battery. that is equipped for eco-friendly disposal in accordance with current regulations.

-

Page 24

Safety Residual risks • Human error resulting from failure to observe the safety guidelines. • Unrepaired damage or defective and worn components. • Insufficient maintenance and testing • Use of incorrect consumables • Maintenance intervals exceeded The manufacturer shall not be held responsi- ble for accidents involving the truck caused by the failure of the operating company to comply with these regulations either intentionally or… -

Page 25: Electromagnetic Radiation

Safety Electromagnetic radiation Electromagnetic radiation The limit values for electromagnetic emissions and for immunity relative to the forklift are those provided by the EN 12895 standard. Non-ionised radiation If the forklift is equipped at the factory or later with devices that emit non-ionising radiation (such as radio transmitters, RFID players, data terminals, scanners, etc), the compatibility of such devices must be verified…

-

Page 26: Vibrations

Safety Vibrations Vibrations Vibrations to which the hands and arms CAUTION are exposed The value expressed above can be used to com- pare forklift trucks of the same category. It cannot The following value is valid for all truck models: be used to determine the operator’s daily expo- •…

-

Page 27: Safety Tests

Safety tests Regular safety inspection of the truck Safety inspection based on time and extraordinary incidents STILL GmbH Hamburg The operating company must ensure that the truck is checked at least once a year, or Regelmäßige Prüfung following noteworthy incidents.

-

Page 28

Safety Safety tests 50018043464 EN — 10/2017… -

Page 29: Overview

Overview…

-

Page 30: Technical Description

Overview Technical description Technical description This robust stand-on electric pallet truck is ideal for loading and unloading lorries, and its high driving speed also makes it easy to transport over longer distances. Chassis • The EXU-S was designed for loading and unloading lorries and has excellent handling on slopes and in the confined spaces of lorries.

-

Page 31

Overview Technical description features variable wheel pressure on the ground proportional to the load on the forks. • For lateral stability, two exclusive STILL twin-wheels have been specially designed for the EXU-S for extreme reliability in the most arduous applications. -

Page 32

Overview Technical description Driver rides standing on «sprung» platform • Depending on the application, the EXU-S is available with two platform types that are ergonomically suited to the operator’s needs. These needs are very different from one type of job to another, so we have designed two different platforms. -

Page 33

Overview Technical description • With each mode, the drive characteristics can be adjusted (speed, acceleration, braking) to precisely match the application or driver preference. • Thanks to the controller’s speed control system, the EXU-S will start smoothly and accelerate to maximum travel speed, regardless of the load on the forks. -

Page 34: Overviews

Overview Overviews vertically with a sling, or from the side using rollers, if used for 2 or 3 work shifts. • Two different battery compartments allow batteries with 450 Ah or 600 Ah capacities to be used. Overviews 0148_003-001 Forks Brake Battery compartment Drive motor…

-

Page 35: Definition Of Directions

Overview Definition of directions Drive controller Load wheel Mounting bracket for accessories (option) Definition of directions The references forwards (1), backwards (3), right (2) and left (4) when describing the position are relative to the driver’s seat. The load is at the front. 0249_003-001 Sample graphics This documentation explains the (usually…

-

Page 36: Control And Display Elements

Overview Control and display elements Control and display elements View of the control elements 0148_003-002 Battery cover Battery compartment lock Cockpit Document holder Diagnostic connector Glove compartment Emergency isolator button 50018043464 EN — 10/2017…

-

Page 37: Cockpit

Overview Control and display elements Cockpit 6 7 8 0148_003-003 Lower button Numbers button Lift button button Hare Horn button Horn button button Lift button Tortoise (scrolling) button Lower button PRG ↑ Numbers button Handle Display Travel control (ON) button Emergency brake switch Numbers button…

-

Page 38: Dead Man’s Zone

Overview Control and display elements Dead man’s zone CAUTION The pallet truck has a foot interlock zone which can cause the truck to be braked. Method of operation The driver must stand with one foot on the foot interlock zone (1) of the driver’s platform. The feet must stay in the area of this platform.

-

Page 39: Markings

Overview Markings Markings Location of designation plates and labels 2329 «Danger of crushing hands» label Nominal value designation plate «No hooking» label «Cold store» label (on cold store version only) «Operating and maintenance manual» label «Danger of crushing feet» label Annual testing label (Germany only) «Hook»…

-

Page 40: Chassis Frame Labelling

Overview Markings (2) This label indicates that you must not lift the truck by hooking onto the cockpit (3) This label indicates that you should consult the operating and maintenance manual before using the truck and before carrying out any maintenance work.

-

Page 41: Data Plate

Overview Markings Data plate NOTE Please indicate the serial number for all technical enquiries. 2327 Model Rated capacity in kg Manufacturer Serial no. Unladen weight (without battery) in kg Year of manufacture EC conformity symbol QR code Battery voltage V Nominal power rating in kW Minimum battery weight Maximum battery weight…

-

Page 42: Options

Overview Options Options Models 1 Platform, access on left side 0148_003-006 2 Platform, access at rear 0148_003-007 Options • Single load wheels • Continuous operation hour meter (with own battery in the tiller head) • Battery charge indicator (for gel battery) •…

-

Page 43: Accessories

Overview Options • Cold store version • Document holder • Preparation for data input terminal • FleetManager • Tray 71 • Various fork gauges and fork lengths • Various load rack sizes • Various types of tyre for the drive wheel •…

-

Page 44

Overview Options 50018043464 EN — 10/2017… -

Page 45: Application

Application…

-

Page 46: Authorised And Safe Use

Application Authorised and safe use Authorised and safe use Intended use of the trucks CAUTION This machine is intended for the transport of loads packed on pallets or in industrial containers de- signed for this purpose, as well as for placing pallets into and removing pallets from stock.

-

Page 47

Application Authorised and safe use • The truck has not been designed to trans- port anyone other than the operator and must not be used for this purpose. • The operator must always stay within the truck clearance. • Stay in the safety area (working area defined by the manufacturer). -

Page 48: Truck Transport And Lifting

Application Truck transport and lifting There must be sufficient distance between the highest part of the truck or the load and the surrounding fixed installations. The height depends on the lift height and the dimensions of the load. Refer to the technical characteristics.

-

Page 49: Climatic Conditions For Transport And Storage

Application Breaking-In Chocking the truck – Secure the truck against rolling and sliding 0148_003-027 with chocks (1). Lashing down the truck – Attach the lashing ropes (2) at the frame. Climatic Conditions for Transport and Storage The forklift must be protected from atmo- spheric agents during transport and storage.

-

Page 50: Checks And Actions Prior To Use

Application Checks and actions prior to use Checks and actions prior to use Visual checks WARNING Damage or other faults on the truck or attachments (special equipment) can result in accidents. If damage or other faults are noticed on the truck or attachments (special equipment) during the following checks, do not use the truck until it has been properly repaired.

-

Page 51

Application Checks and actions prior to use – No visible damage (e.g. deformation, cracks, heavy wear, hairline cracks) to forks (1) and other lifting devices. – Inspect the wheels and load wheels (2) for strings, fibres and any other objects that could hinder their free rotation. -

Page 52

Application Checks and actions prior to use – The battery cover (5) must be closed. – The cover (3) must be fitted. • Check that the warning and safety labels are complete and intact; see ⇒ Chap- ter «Location of designation plates and la- bels», P. -

Page 53

Application Checks and actions prior to use condition. Check that they are working correctly • Check that the start/stop key works cor- rectly • Check that the horn works correctly • Check that the buttons and the control throttles on the tiller are working correctly •… -

Page 54: Connecting The Battery Plug (Charging Station)

Application Start-up Connecting the battery plug (charg- ing station) – Disconnect the battery socket (1) from the charging station and insert into the plug on the truck. – The latch (2) must be closed. – Close the battery cover (3). 0148_003-011 Start-up Turning on the truck…

-

Page 55: Entering The User Code

Application Start-up Entering the user code – Press the key (on) (6). The display (4) shows the message (8). This Code message switches off after approximately one second. You can then enter the 4-digit user code. The digits are entered in the same way as on a mobile phone.

-

Page 56: Starting With Fleetmanager (Optional)

Application Start-up – The digit will be deleted and the flashing line (9) will reappear. It is now possible to enter digits again. – After the fourth digit has been entered, confirm this code by pressing (5). PRG ↲ The name of the truck manufacturer is displayed.

-

Page 57: Hour Meter

Application Start-up Hour meter The operating hours (1) appear approx. 4 to 5 seconds after starting the truck, accom- panied by the hourglass symbol (2). The total hours are indicated from when the truck is first commissioned. The hour meter totals during travel.

-

Page 58: Display Of Time To Next Servicing

Application Start-up CAUTION Deep discharging damages the battery. The battery must immediately be charged as deep discharging begins. Display of time to next servicing – Press the (scrolling) button (4) to PRG ↑ display the time remaining until the next scheduled servicing.

-

Page 59: Operating The Horn

Application Start-up Operating the horn – Press the horn button (2) on the cockpit. 1047_003-008 Check of brake and presence area – Start the truck slowly with the throttle (1). 0148_003-012 50018043464 EN — 10/2017…

-

Page 60: Checking The Emergency Brake Button

Application Start-up – Step off the presence area (2) while leaving the throttle actuated. 0148_003-013 Checking the emergency brake button – Drive the truck slowly using the traction control (4). – Press the emergency brake button (5). The truck will be braked and remains stationary. signal appears on the display –…

-

Page 61: Driving

Do not sit on the truck when driving. EXU-S 22/24 trucks are designed for opera- tion in ride-on mode, therefore: • Do not operate the truck when sitting. • Never use the truck as a climbing aid.

-

Page 62: Before Driving

Application Driving Before driving Persons in the danger area Before and during operation of the truck, the driver must ensure that no person is standing in the danger area of the truck. A warning signal must be given in the event of danger to persons.

-

Page 63: Dimensions Of Roads And Working Aisles

Observe your local and national regulations. Please see ⇒ Chapter «VDI data sheet for 0148_003-014 standard EXU-S 22», P. 6-101. The truck may only be used on roadways without any tight curves, excessive slopes or passages that are too narrow or too low.

-

Page 64: Emergency Stop Procedure

Application Driving representative must ensure that unauthorized persons keep away from the working area. Hazard areas Hazardous areas on roadways must be marked with the usual traffic signs or, if necessary, by additional warning signs. Emergency stop procedure In an emergency, all truck functions can be cut off.

-

Page 65: Driving In Rider Mode

Application Driving Driving in rider mode – Step on the platform with both feet and step on the presence area (1). NOTE The pallet truck is turned on. WARNING There should be no objects lying on the floor of the driver’s platform, whose weight could activate the dead man’s switch under the mat.

-

Page 66: Selecting The Driving Mode

The truck is steered by turning the cockpit in range (1). The turning radius (Wa) depends on the fork length and the battery. (See ⇒ Chapter «VDI data sheet for standard EXU-S 22», P. 6-101) 0148_003-017 Brakes WARNING The surface finish influences the driving and bra- king behaviour of the truck.

-

Page 67

Application Driving Soft braking NOTE The truck is braked electrically. – Release throttle (3) or (4) when driving. 0148_003-018 – Leave the presence area (5). Average braking – Operate the throttle (3) or (4) in the opposite direction. Emergency braking CAUTION This type of braking may only be used in an emer- gency. -

Page 68: Automatic Shutdown

Application Lifting The truck is braked by the electromagnetic brake. Automatic shutdown NOTE If you leave the truck with the control turned on, it will be shut off automatically after approx. 15 minutes. The truck can only be operated again after the driver code is entered. The delay time is adjustable.

-

Page 69

Application Lifting Lowering the forks – Press the lower button (1). The forks are lowered. Their movement can be stopped at any time by releasing the button. 0148_003-020 50018043464 EN — 10/2017… -

Page 70: Load Placement

Application Load placement Load placement Safety regulations when handing loads DANGER DANGER Wear protective footwear. Risk of injury and crushing for the operator and for any pedestrians! Risk of damage to the truck and the goods CAUTION During movement of the truck and the loads, espe- cially in reverse gear, be careful not to hit any obst- Transporting passengers is strictly prohibited.

-

Page 71: Before Picking Up A Load

Before picking up a load Load capacity Do not exceed the load capacity of the truck. See ⇒ Chapter «VDI data sheet for standard EXU-S 22», P. 6-101. WARNING Never exceed the stated maximum load capacities! Otherwise truck stability will not be ensured.

-

Page 72: Taking Up Load

Application Load placement Taking up load – Approach the load with caution and with as inserted far enough in that the load is resting much precision as possible. against the fork carriage. The load centre of gravity must be centred between the forks. –…

-

Page 73: Depositing A Load On The Ground

Application Load placement DANGER When travelling and transporting the load, be aware of the side clearance of the load, particularly when cornering. Avoid hitting shelving and objects in your path. DANGER Danger of load tipping over Avoid sudden starts and stops. Approach corners slowly and carefully.

-

Page 74: Driving Up And Down On An Incline

Application Load placement Driving up and down on an incline When driving up and down on an incline, the load must always be carried uphill. It is only permitted to drive on inclines which are identified as suitable for traffic and which can be safely negotiated according to the technical data of the truck.

-

Page 75: Driving On Loading Bridges

Application Load placement Driving on loading bridges Before crossing a loading bridge, the operator must make sure it is properly attached and secured and its load capacity is sufficient. Cross the loading bridge slowly and carefully. The driver must be sure that the vehicle to be entered is secured sufficiently against movement and that it can support the load of the forklift truck.

-

Page 76: Using The Truck On Inclines, Loading Bridges And Lifts

Application Load placement Using the truck on inclines, loading bridges and lifts. Driving on inclines Using the truck on a lift When driving the truck up or down inclines, Using the truck on lifts is only allowed if the you must not exceed the values for inclines lift has sufficient load capacity (check the indicated in the chapter «Technical data».

-

Page 77: Cold Store Usage (Optional)

Application Cold store usage (optional) Cold store usage (optional) Designation Your truck is fitted with special equipment for use in cold stores. It can be used for two operating ranges and carries a cold store label. The cold store equipment for the truck consists of using specialised oils (for the hydraulic installation and the gears) suitable for cold stores.

-

Page 78

Application Cold store usage (optional) – Drive the truck for approximately 5 minutes and operate the brakes several times to ensure the truck operates safely. – Operate all the lifting functions several times. This warming up phase is required to allow the oil to reach operating temperature. -

Page 79: Digicode

Application Digicode Digicode Digicode control Access to the electronic control is granted with three different codes: • Driver’s code • master code • service code Driver’s code The driver’s code consists of four digits and must be created by the Pool Manager. It is used for the regular utilisation and opera- tion of the truck by the driver and operator.

-

Page 80: Adding The Master Code

Application Digicode Service code The service code is only intended for the after-sales service. It allows the diagnosis of the truck for inspections and the access to the driver’s and master code. Adding the master code NOTE The truck is turned off, the battery is connec- ted.

-

Page 81: Deleting A Master Code

Application Digicode – Confirm with the (enter) button (4). PRG ↲ 1044_505-012 A flashing line cursor (8) will appear in the display. – Enter the desired new 4-digit master code with the buttons (1), (2) or (3) as described above. NOTE The controller can store a maximum of five master codes.

-

Page 82

Application Digicode – Press the (ON) button (5). – Enter the valid 4-digit master code with the buttons (1), (2) and (3). 1044_505-009 – Scroll with the (scrolling) button (6) PRG ↑ 1044_505-010 until (7) appears in the display. – Confirm with the (enter) button (4) PRG ↲… -

Page 83: Adding A Driver’s Code

Application Digicode – Confirm with the (enter) button (4) PRG ↲ 1044_505-013 until the master code (9) to be deleted blinks (an example is shown). – Then release the button. (10) will 1044_505-015 appear again in the display. – Press the (scrolling) button (6) until PRG ↑…

-

Page 84

Application Digicode – Scroll with the (scrolling) button (6) PRG ↑ 1044_505-016 until (7) appears in the display. USEr – Confirm with the (enter) button (4) PRG ↲ 1044_505-011 until (10) appears in the display. – Confirm with the (enter) button (4). PRG ↲… -

Page 85: Deleting A Driver’s Code

Application Digicode Deleting a driver’s code NOTE The truck is turned off, the battery is connec- ted. – Press the (ON) button (5). – Enter the valid 4-digit master code with the buttons (1), (2) and (3). 1044_505-009 – Scroll with the (scrolling) button (6) PRG ↑…

-

Page 86

Application Digicode – Confirm with the (enter) button (4) PRG ↲ 1044_505-013 until the driver’s code (9) to be deleted blinks (an example is shown). – Then release the button. (10) will 1044_505-015 appear again in the display. – Press the (scrolling) button (6) until PRG ↑… -

Page 87: Error Codes

Application Error codes Error codes Error code 11 12 If an error code such as (15) appears, E380 shut the truck off by pressing button (10) and repeat the start-up ⇒ Chapter «Start-up», P. 46. If the error code persists, call your Service. 1044_505-024 1044_505-019 Error code Description…

-

Page 88: Battery Electrolyte Level Indicator Led (Optional)

Application Battery electrolyte level indicator LED (optional) Error code Description Action Right button operated at power-up. Release the right button (12). Horn Horn E380 Release the right button Lowering Right button operated at power-up. Lowering E381 (13). Right button operated at power-up. Release the right button (14).

-

Page 89: Hoisting The Truck

Danger to life! Do not step or stand under a suspended load. 0148_003-026 Towing procedure Towing the truck is only possible if there is still a power supply, otherwise the electric brake is still applied. NOTE The brake can be released. Please contact your after-sales service.

-

Page 90: Handling The Battery

Application Handling the battery Handling the battery Battery type The pallet stacker can be equipped with different types of batteries. Observe the information on the nattery type plate. Also refer to ⇒ Chapter «Technical data», P. 99 for this purpose. WARNING The weight and dimensions of the battery affect truck stability.

-

Page 91: Opening/Closing The Battery Compartment

Application Handling the battery Safe parking Park the truck securely before carrying out work on the battery. The truck can only be operated when the battery cover is closed and the battery outlet is inserted. If the truck is enabled for side removal of the battery, the truck can only be operated once the battery is fixed in place properly using the battery locking system.

-

Page 92: Changing The Battery

Application Handling the battery – Disconnect the battery connector (3). WARNING Switch the truck and charger off before disconnec- ting the male and female connectors. – Connect the battery connector to the charger connector. NOTE Observe the information in the operating instructions for your battery and battery charger (equalising charge).

-

Page 93: Changing The Battery With Crane

Application Handling the battery DANGER Danger to life! No-one should be under a raised load. Changing the battery with crane Maintain a safe distance for battery removal to avoid damaging the truck. – Open the battery compartment (1). – Unplug the battery connector. In order to avoid short-circuits,it is recom- mended that batteries with polar terminals or unprotected connections be covered with a…

-

Page 94: Changing The Battery With Lateral Removal Trolley

Application Handling the battery Changing the battery with lateral removal trolley CAUTION When removing or installing the battery keep your hands away from chassis and battery! There is an increased risk of squeezing your hands! – Open the battery cover (1). –…

-

Page 95: Decommissioning

Application Decommissioning Decommissioning Safe parking of the truck – Park the truck in a dry, clean and well- ventilated area. WARNING Do not park the truck on gradients. In exceptional cases, secure the truck with chocks. – Lower the forks (1) on the ground. WARNING –…

-

Page 96: Storage

Application Storage Storage Measures when storing the stacker for a longer period of time If the stacker is to be held in storage for a longer longer period of time, carry out the following corrosion protection measures. If the stacker is to be stored for over two months, park it in a clean and dry storage area, which is also well ventilated and frost-free.

-

Page 97: Taking Back Into Service After Storage

Application Storage If the truck is to be taken out of service for an even longer period, contact your after-sales service. Taking back into service after storage If the pallet stacker has been out of service for over six months, it must be inspected carefully before it is taken back into service.

-

Page 98

Application Storage 50018043464 EN — 10/2017… -

Page 99: Maintenance

Maintenance…

-

Page 100: General Information

Maintenance General Information General Information To keep your forklift in good condition, carry NOTE out the servicing indicated regularly, within the Contact the authorised service network for times indicated and using the consumption a maintenance contract appropriate to your materials provided for that purpose, as speci- forklift.

-

Page 101: Scheduled Maintenance

Maintenance Scheduled maintenance Scheduled maintenance Summary table of maintenance operations EXU-S Operations Completed Intervals in hours 1000 2000 5000 Checks and tests prior to commissioning Check the oil level in the hydraulic system and the transmission gear Test the insulation between the chassis and the electric motors Test the insulation between the chassis and the electronic control…

-

Page 102

Maintenance Scheduled maintenance 5000 = To be repeated every 5000 hours. For example at 5000, 10,000, 15,000, 20,000 etc.) ENVIRONMENT NOTE During maintenance operations, follow the instructions provided in the section «Safety regulations relative to operating materials» in «Chapter 2». 50018043464 EN — 10/2017… -

Page 103: Maintenance As Required

Maintenance Maintenance as required Maintenance as required Cleaning the Forklift Cleaning depends on the type of use and the Use water-dampened rags to clean the parts workplace. Should the truck come into contact of the body. with highly aggressive elements such as salt CAUTION water, fertilizers, chemical products, cement, etc., it should be cleaned as carefully as…

-

Page 104

Maintenance Maintenance as required – Disconnect the battery connector (3). – Remove the bonnet(2) to gain access to the fuse carrier. 0148_003-045 The following fuses are located on the fuse carrier: 1 Main fuse 400 A 2 Fuse F3 7.5 A 3 Fuse F4 7.5 A 4 Fuse F5… -

Page 105: Decommissioning

Maintenance Decommissioning Decommissioning General Information The operations to be performed for «Tem- porary decommissioning» and «Permanent decommissioning» are listed in this chapter. 50018043464 EN — 10/2017…

-

Page 106: Forklift Towing

Maintenance Decommissioning Forklift Towing The forklift may not be towed in the case of breakdown. The forklift must be lifted with due caution, as described on the preceding pages. Temporary Putting Out of Commission The following operations must be performed •…

-

Page 107: Technical Data

Technical data…

-

Page 108: Dimensions

Technical data Dimensions Dimensions 50018043464 EN — 10/2017…

-

Page 109: Vdi Data Sheet For Standard Exu-S 22

Technical data VDI data sheet for standard EXU-S 22 VDI data sheet for standard EXU-S 22 Characteristics EXU-S 22 EXU-S 22 Rear access Side access Type of platform Electric Drive: electric, diesel, petrol, LPG. Driving mode: manual, Standing pedestrian, ride-on…

-

Page 110

Technical data VDI data sheet for standard EXU-S 22 EXU-S 22 EXU-S 22 4/1x + 2 Number of wheels (x = drive side/load side drive) b10 (mm) Track drive side 348/388/498 b11 (mm) Track load side Dimensions EXU-S 22 EXU-S 22… -

Page 111

Technical data VDI data sheet for standard EXU-S 22 Performance data EXU-S 22 EXU-S 22 Driving speed with/without load km/h 10/12 Lifting speed with/without load 0.043/0.062 Lowering speed with/without load 0.068/0.065 Surmountable gradient with/without load 10%/15% Acceleration time (over 10 laden/unladen 6.2/4.6… -

Page 112

Technical data VDI data sheet for standard EXU-S 22 (5) With forks raised (6) Values calculated with W and fork length l = 990 mm Edition dated 22/10/2015 50018043464 EN — 10/2017… -

Page 113: Vdi Data Sheet For Standard Exu-S 24

Technical data VDI data sheet for standard EXU-S 24 VDI data sheet for standard EXU-S 24 Characteristics EXU-S 24 EXU-S 24 Rear access Side access Type of platform Drive: electric, diesel, Electric petrol, LPG Driving mode: manual, Standing pedestrian, ride-on standing, ride-on seated, order picking 2400…

-

Page 114

Technical data VDI data sheet for standard EXU-S 24 EXU-S 24 EXU-S 24 b10 (mm) Track drive side 348/388/498 b11 (mm) Track load side Dimensions EXU-S 24 EXU-S 24 h3 (mm) Lift Height of cockpit in h14 (mm) min/max 1030 operating position Step plate height h7 (mm) -

Page 115

Technical data VDI data sheet for standard EXU-S 24 EXU-S 24 EXU-S 24 Acceleration time (over 10 laden/unladen 6.3/4.8 metres) Service brake electromagnetic Electric motors EXU-S 24 EXU-S 24 Travel motor, rating S2 = 60min Lifting motor, rating S3 = Battery in accordance with DIN 43 531/35/36 A, B, C, Battery voltage/nominal… -

Page 116: Turning Radius And Load Distance Exu-S

Technical data Turning radius and load distance EXU-S Turning radius and load distance EXU-S EXU-S 22 Turning radius (Wa) and load distance (x) with forks lowered (a) Battery compartment Battery compartment 70 (3PzS) 71 (4PzS) 345 — 465 Ah 560 — 620 Ah…

-

Page 117: Wheels And Tyres

Technical data Wheels and tyres Legend: a = for value with forks raised deduct 113 mm b = available only when b5 = 560 mm c = useful for transporting three Euro pallets on the short side d = useful for transporting two Euro pallets on the long side Wheels and tyres Approved types of wheels…

-

Page 118: Supply Table Exu-S Exu-Sf

FUCHS Renolin PG 220 1.1 litres gear oil Lifting hydraulics oil Olio idraulico HLF 32 2.5 litres Oil for pivot wheels (only if the «STILL AP31 hydraulic oil DRIVEspeed» version is present) Generic lubricant Tutela MP 02 Cold storage version…

-

Page 119

Index Deleting a master code ….73 Digicode control ….71 Accessories . -

Page 120

Index Models ……34 Service code ….. 72 Soft braking . -

Page 122

STILL GmbH 50018043464 EN – 10/2017…

This manual is also suitable for:

Exu-s 24

![]()

Forklift

Super Moderator

- Joined

- Mar 27, 2015

- Messages

-

2,511

- Likes

- 154

-

Download this document, you need

0

Gallons

Download Now

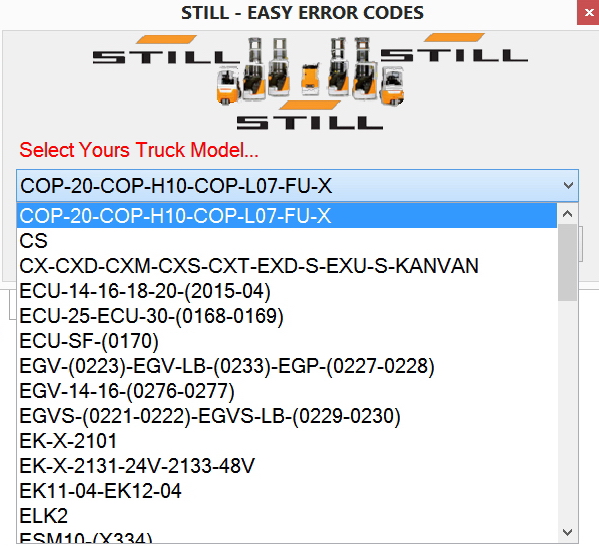

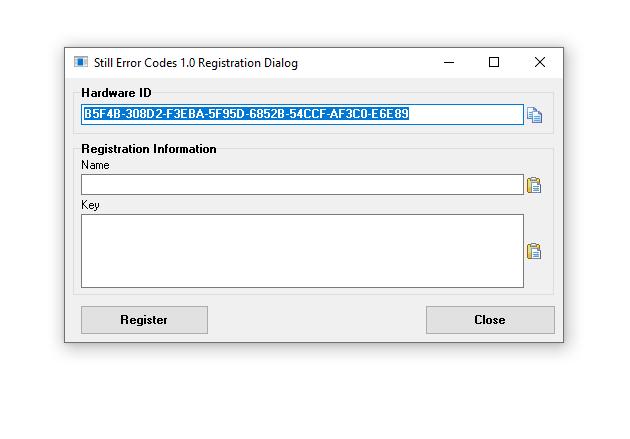

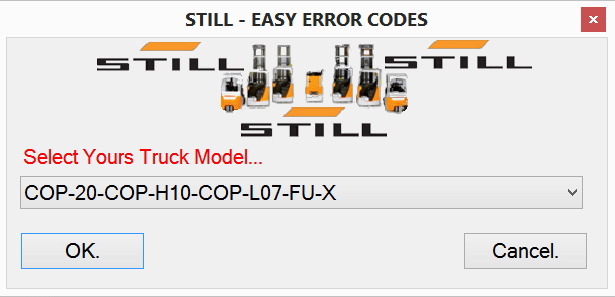

1/ Still Forklift Easy Error Codes

2/ This PC Lock Send Me Yours Name + HWID

3/ One Key for one PC

4/ After install Comment on below «Yours Name + HWID» or sent to email: «autorepairmanuals.ws@gmail.com»

COP-20-COP-H10-COP-L07-FU-X.txt

CS.txt

CX-CXD-CXM-CXS-CXT-EXD-S-EXU-S-KANVAN.txt

ECU-14-16-18-20-(2015-04).txt

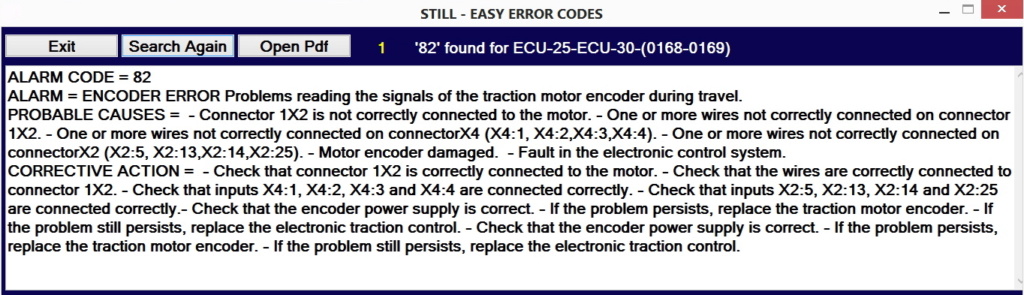

ECU-25-ECU-30-(0168-0169).txt

ECU-SF-(0170).txt

EGV-(0223)-EGV-LB-(0233)-EGP-(0227-0228).txt

EGV-14-16-(0276-0277).txt

EGVS-(0221-0222)-EGVS-LB-(0229-0230).txt

EK-X-2101.txt

EK-X-2101_INFO.txt

EK-X-2131-24V-2133-48V.txt

EK-X-2131-24V-2133-48V_INFO.txt

EK11-04-EK12-04.txt

ELK2.txt

ESM10-(X334).txt

EXD20-EXD-SF20-EXU-SF20-(0283-0284-0179).txt

EXU22.txt

EXV-10-10Basic-12-12i-14-14i.txt

EXV-10-10Basic-12-12i-14-14i_INFO.txt

EXV14-16-20-(i)-EXV-SF14-16-20-(i)-(0323-0334)-EXP-(0301-0303-0305).txt

EXV14-16-20-(i)-EXV-SF14-16-20-(i)-(0323-0334)-EXP-(0301-0303-0305)_INFO.txt

FM-X-(1900-1922).txt

FM-X-(1900-1922)_INFO.txt

FM-X-(1900-1922)_OLD.txt

FM-X-1801.txt

FM-X-1801_INFO.txt

FMI-Typ-429.txt

FMI-Typ-447.txt

FMI-Typ-451.txt

FS-X33.txt

FV-X-12-12i-16-16i.txt

GX-X-GX-Q.txt

GX-X-GX-Q_INFO.txt

iGo-neo-CX-20-(1063).txt

Lithium-ion-technology.txt

MX-X-2332-2334.txt

MX-X-2332-2334_INFO.txt

MX-X-2332-2334_old.txt

MX-X-MX-Q-Generation-1-2-80V.txt

MX-X-MX-Q-Generation-1-2-80V_OLD.txt

MX-X-MX-Q-Generation-3-48V.txt

MX-X-MX-Q-Generation-3-48V_OLD.txt

MX-X-MX-Q-Generation-3-80V.txt

MX-X-MX-Q-Generation-3-80V_OLD.txt

MX-X-MX-Q-Generation-4-48V.txt

MX-X-MX-Q-Generation-4-48V_OLD.txt

MX-X-MX-Q-Generation-4-80V.txt

MX13-3-MX15-3-MX13-3i-MX15-3i.txt

OPX-LTX50.txt

OPX-LTX50_INFO.txt

R07—25-R08-20-2017.txt

R07-25-R08-20.txt

R07-25-R08-20_INFO.txt

R20-2008-2014-2017-2024-2037-2044.txt

R20i-2015-2045-2049.txt

R60-(S60).txt

R60-6022-6029-6042-6052.txt

R60i-6033-6035-6053-6055.txt

R60i-6036-6039.txt

R70.txt

RX20-RX60_INFO.txt

RX20.txt

RX50-5051-5055.txt

RX50-5051-5055_INFO.txt

RX50-5060-5066.txt

RX50-5060-5066_INFO.txt

RX60.txt

RX70.txt

RX70_INFO.txt

SU-SD-SV.txt

X_Not_Sorted_Model_List.txt

X_Sorted_Model_List.txt

Last edited by a moderator: Feb 20, 2020

More the random threads same category:

- STILL STEDS Forklifts 8.17 R2 [02.2017] Full Instruction + Activation

- STILL STEDS 8.16.R2 Plus [05.2016] Full Instruction + Activation

- Still Steds 8.14 FULL

- STILL Some Error Code PDF

- Still Steds Navigator Forklifts 8.19 R2 [02.2019]

- STILL STEDS Forklifts 8.15 R2 [08.2015] Full VM

- Prosecco Multi KG V4 + ProSecCo Activator

- STETI EPC (Steinbock) Forklifts v3.6 2003 Spare Parts Catalog

- STILL STEDS Forklifts 8.18 R3 [03.2018] Full Instruction

- Forklift ProSecCo KG 2015 v2 (Clark,Linde,Lidos,Liebherr,Valtra,Widos,Jeti,Still)

- Still Steds Navigator Forklifts 8.18 R8 [09.2018] Full Instruction

- Still Steds Navigator Forklifts 8.20 R2 [02.2020] Full Instruction

- Forklift ProSecCo KG 2016 v1

- Still Forklift ProSecCo KG 2016v2

- Still Steds Navigator Forklifts 8.19 R8 2020 [08.2019] Full Instruction

![]()

Master

Administrator

- Joined

- Sep 3, 2012

- Messages

-

17,463

- Likes

- 709

1/ Still Forklift Easy Error Codes

2/ This PC Lock Send Me Yours Name + HWID

3/ One Key for one PC

4/ After install Comment on below «Yours Name + HWID» or sent to email: «autorepairmanuals.ws@gmail.com»

empilhomat

New Member

- Joined

- Feb 16, 2021

- Messages

-

1

- Likes

- 0

dmis

- Joined

- Oct 29, 2022

- Messages

-

1

- Likes

- 0

![]()

Admin

Administrator

- Joined

- Oct 26, 2015

- Messages

-

488

- Likes

- 14

![]()

STILL Forklift Fault Codes

STILL Forklift Fault Codes

STILL Forklift Fault Codes.pdf

Adobe Acrobat Document

2.3 MB

![]()

STILL RX 50 Operator Manual

STILL RX 50 Operator Manual

STILL RX 50 Operator Manual.pdf

Adobe Acrobat Document

7.8 MB

![]()

STILL FM X Operator Manual

STILL FM X Operator Manual

STILL FM X Operator Manual.pdf

Adobe Acrobat Document

5.7 MB

![]()

STILL RX 60 16 18 20 Operator Manual

STILL RX 60 16 18 20 Operator Manual

STEEL RX 60 16 18 20 Operator Manual.pdf

Adobe Acrobat Document

1.2 MB

![]()

STILL RX 20-E3 Operator Manual

SILL RX 20-E3 Operator Manual

STEEL RX 20-E3 Operator Manual.pdf

Adobe Acrobat Document

5.7 MB

![]()

STILL RX 70 16 20 Diesel Operator Manual

STILL RX 70 16 20 Diesel Operator Manual

STEEL RX 70 16 20 Diesel Operator Manual

Adobe Acrobat Document

5.3 MB

![]()

STILL RX 70 20 35 Operator Manual

STILL RX 70 20 35 Operator Manual

STEEL RX 70 20 35 Operator Manual.pdf

Adobe Acrobat Document

5.0 MB

![]()

STILL RX 60 60 80 Operator Manual

STILL RX 60 60 80 Operator Manual

STILL RX 60 60 80 Operator Manual.pdf

Adobe Acrobat Document

4.8 MB

![]()

STILL RX 70 40 50 Operator Manual

STILL RX 70 40 50 Operator Manual

STILL RX 70 40 50 Operator Manual.pdf

Adobe Acrobat Document

6.0 MB

![]()

STILL RX 60 25 35 Operator Manual

STILL RX 60 25 35 Operator Manual

STILL RX 60 25 35 Operator Manual.pdf

Adobe Acrobat Document

6.2 MB

![]()

STILL RX 70 60 80 Operator Manual

STILL RX 70 60 80 Operator Manual

STILL RX 70 60 80 Operator Manual.pdf

Adobe Acrobat Document

5.2 MB

Some STILL Forklift Truck Operator Manuals PDF, Fault Codes DTC are above this page — FM, RX.

STILL GmbH was founded in 1920 in Hamburg and is named after its founder Hans Still. It all started with a small electrical workshop where the electric motors

were repaired and semi-automatic emergency power supply units were manufactured.

After a considerable period of time, including the WW2, in 1949, Still presented his first loader. From that moment a new history of the company began — already under the sign of

the manufacturer of forklifts.

Today there are several enterprises in STILL.

The expansion began in 1989, when SAXBY was acquired in 1997 Wagner purchased.

In 2001, the production site in South America began operating. Since 2006, STILL belongs to Kion Group.

In addition to 4 factories, Still has 14 branches in Germany, 20 subsidiaries and an extensive dealer network around the world. The