Kyocera это профессиональная и достаточно дорогая печатная техника, но зато очень качественная, качестве печати у нее выше чем у аналогов так же как и срок службы. Но как и с любой другой возникают различные проблемы. Сегодня рассмотрим одну ситуацию на примере МФУ Kyocera ECOSYS M2135dn. По непонятным причинам МФУ перестает брать бумагу из основного лотка и выдает сообщение о том что бумаги нет, хотя она там конечно же есть. Сообщение выглядят следующим образом «Кассета 1 не загружена» и «Загрузите бумагу в кассету 1». Есть две причины (по крайне мере которые мне известны) которые могут к этому привести, первая это в настройка кто-то поменял устройство подачи по умолчанию и вторая это сломан флажок датчика наличия бумаги в лотке.

M2135dn не берет бумагу с основного лотка

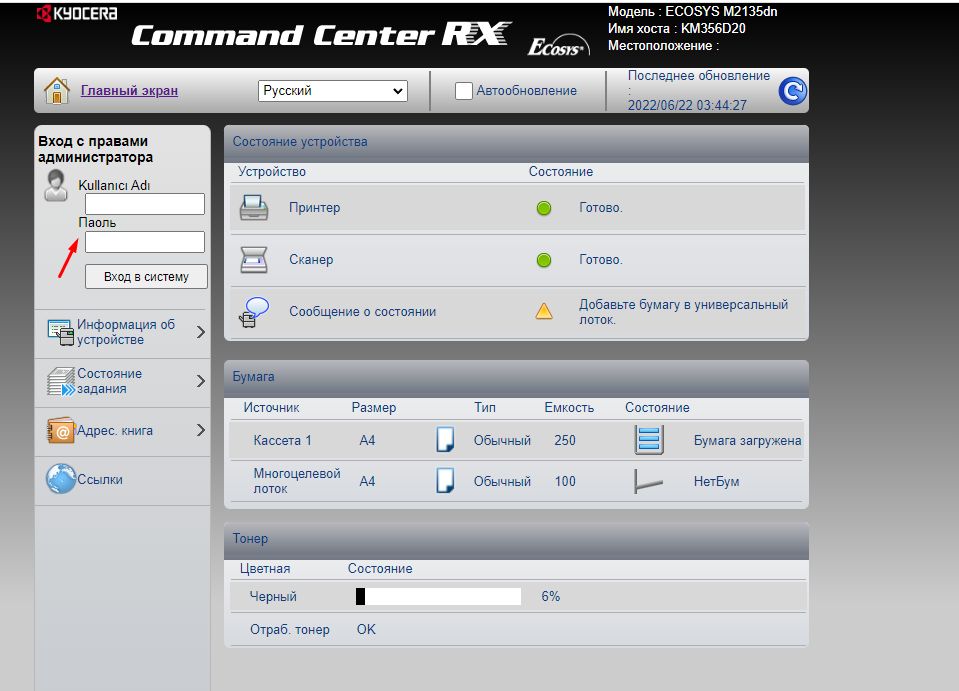

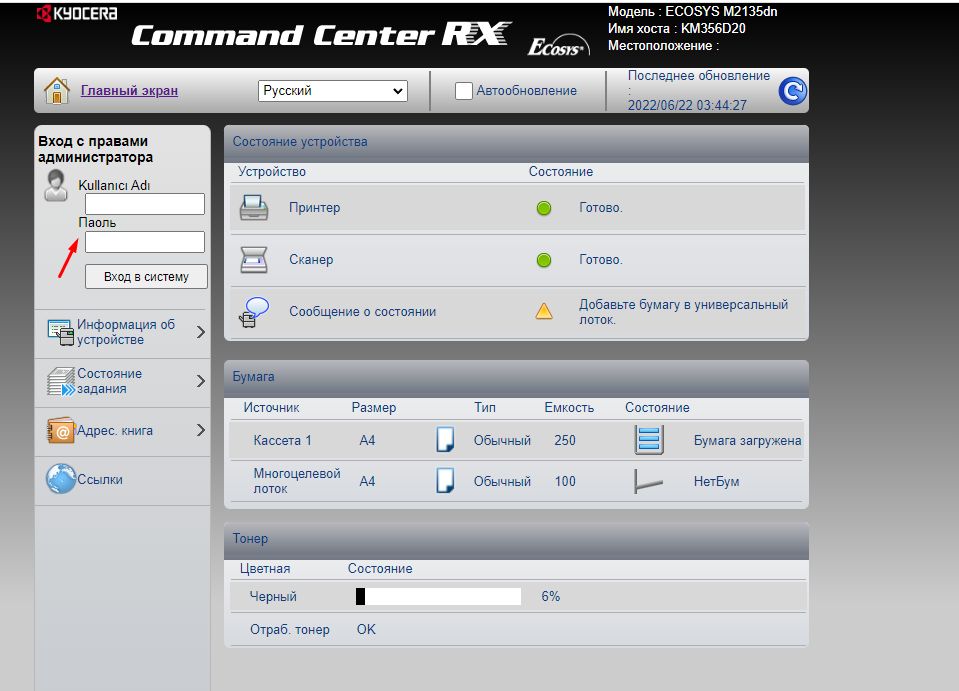

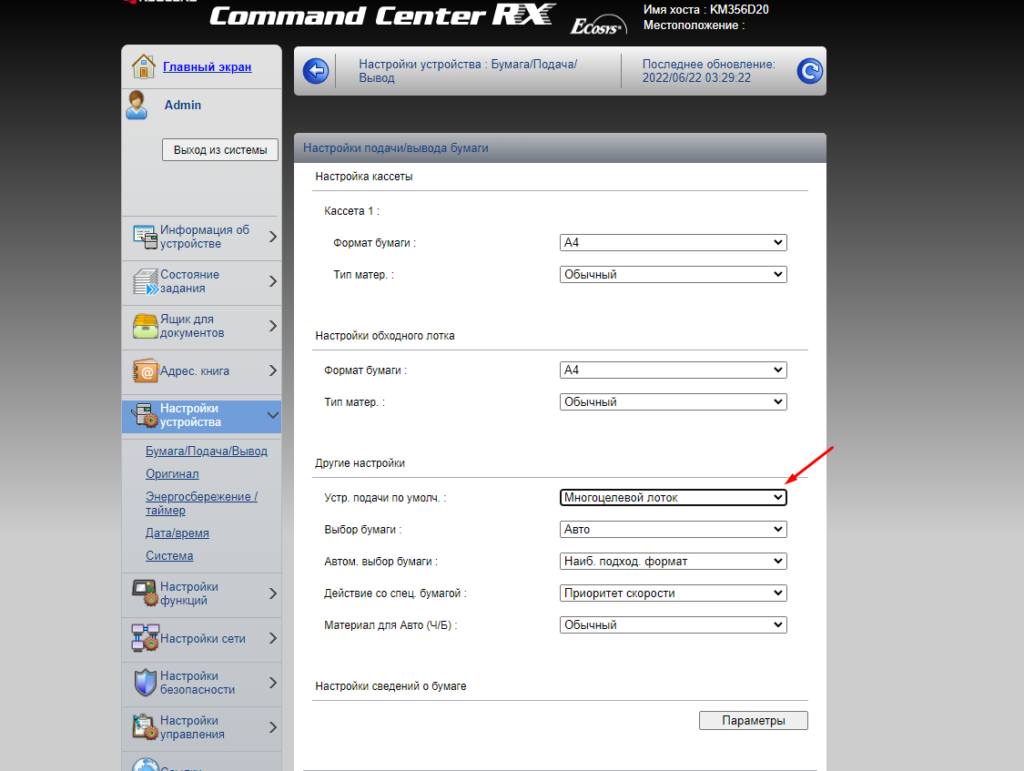

Для начала нужно проверить настройки, сделать это намного проще и удобней через веб интерфейс. Открываем браузер вводим IP адрес принтера далее проходим авторизацию(стандартный логин пароль для этой модели Admin/3500) .

Сервисные пароли Kyocera — https://mita.by/articles/servisnyie-paroli-kyocera/

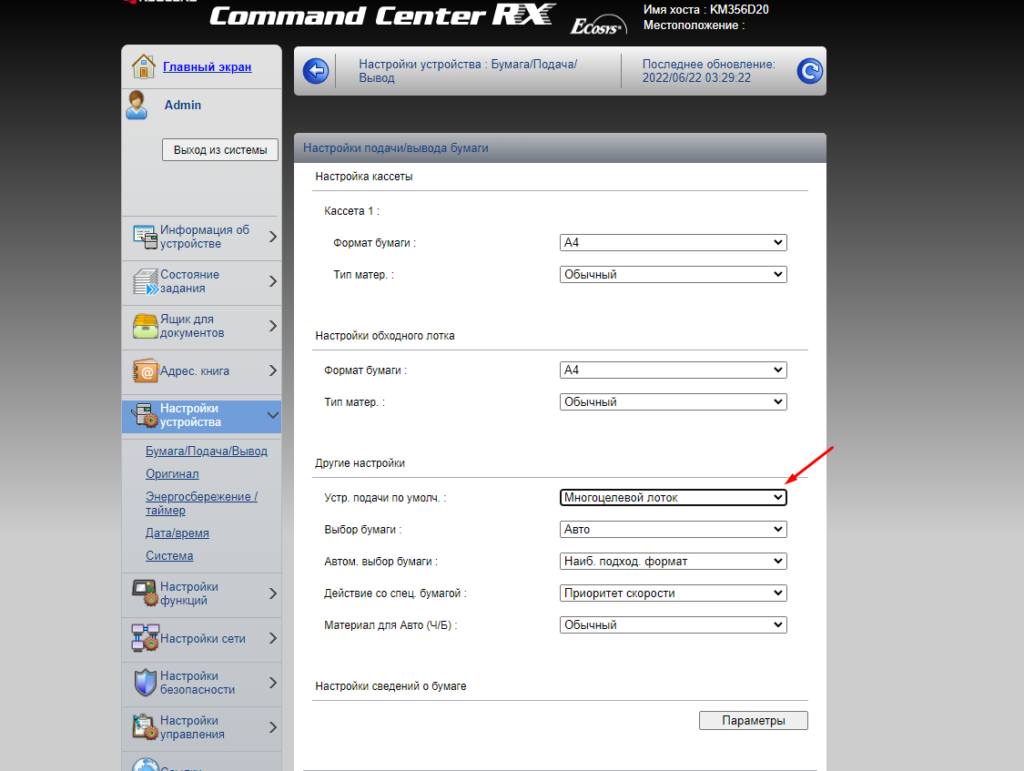

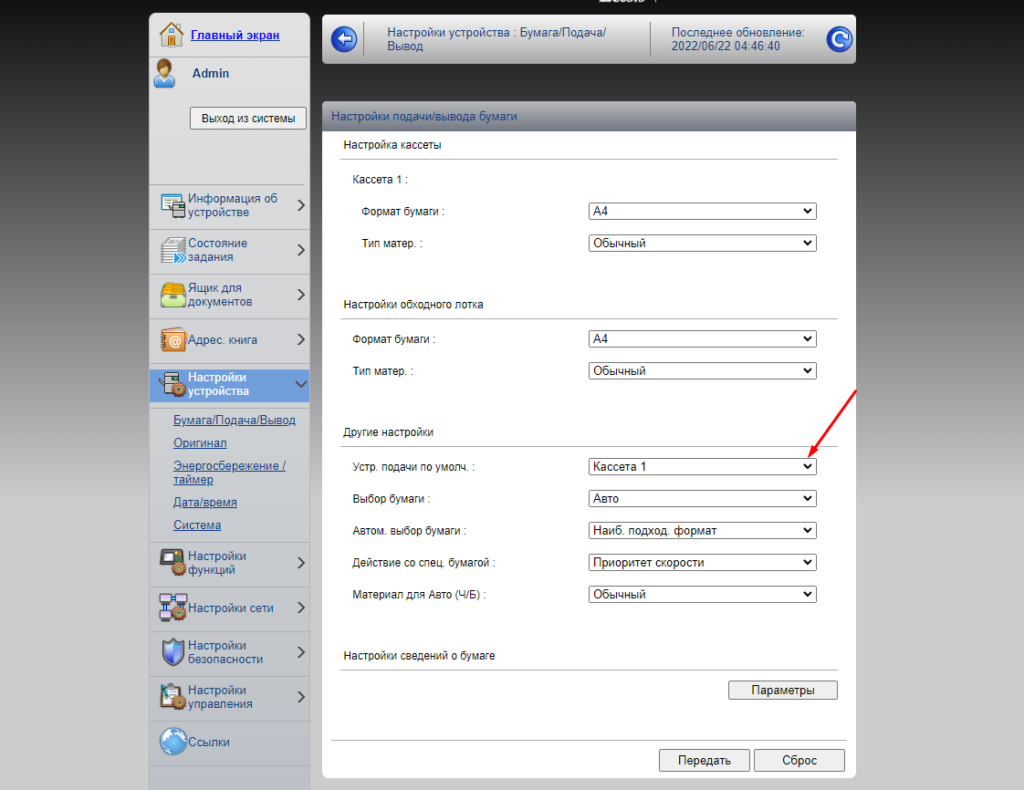

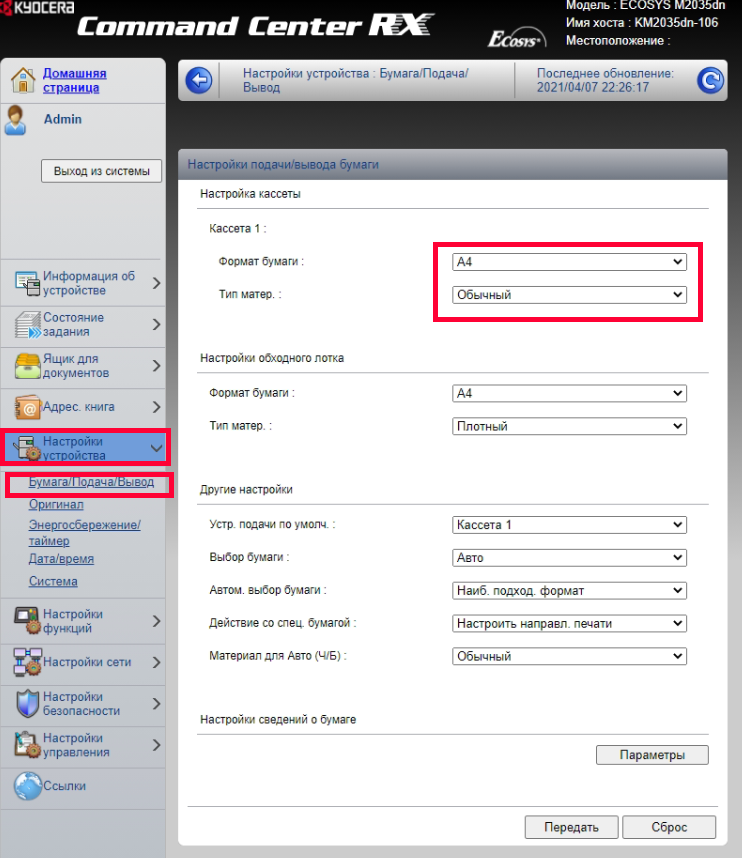

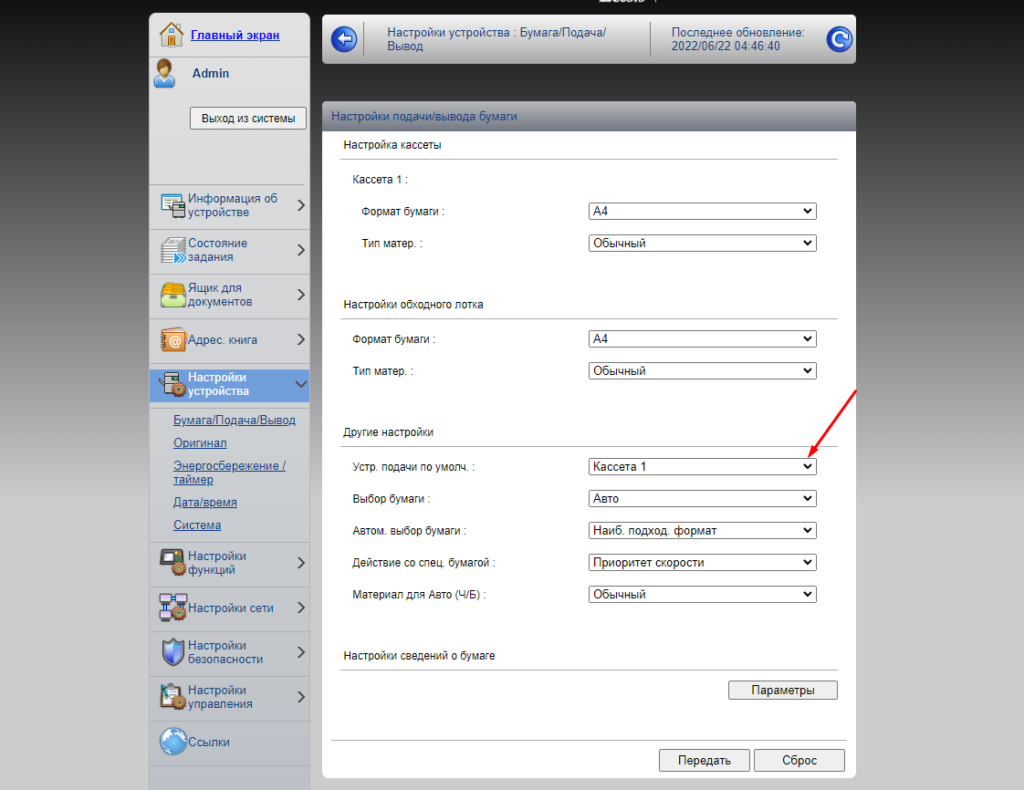

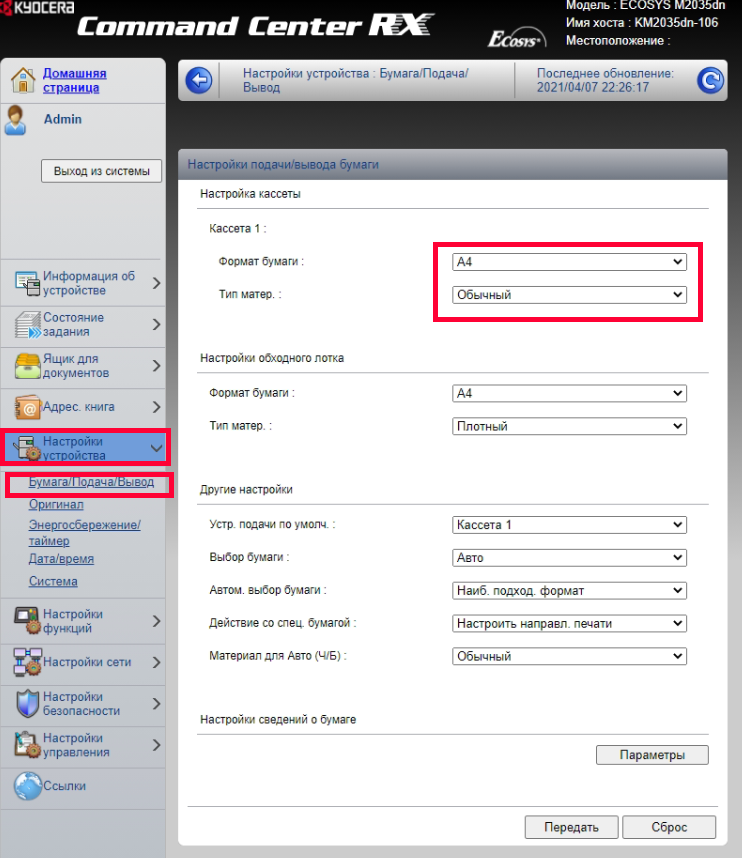

Далее открываем раздел «Настройки» и выбираем пункт «Бумага/Подача/Вывод». В открывшемся окне в пункте «Устр. подачи по умолч» должно стоять «Кассета 1» многоцелевой лоток это лоток ручной подачи.

Изменяем и сохраняем настройки.

Если вы не совсем в этом понимаете или кто-то до вас там что-то непонятное настроил можно вообще сделать сброс до заводских настроек.

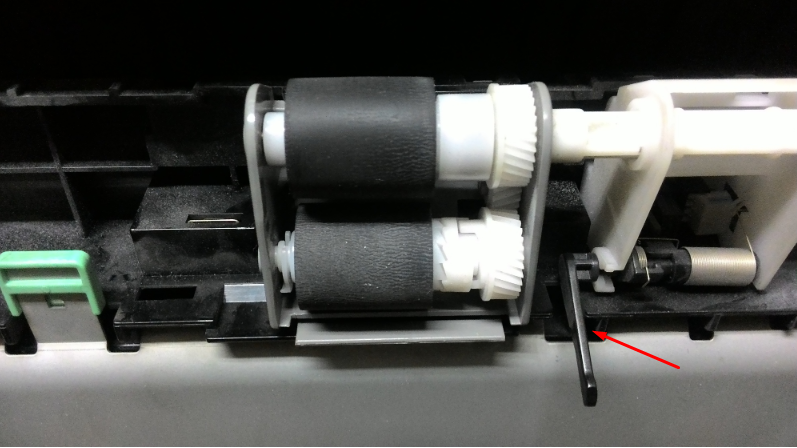

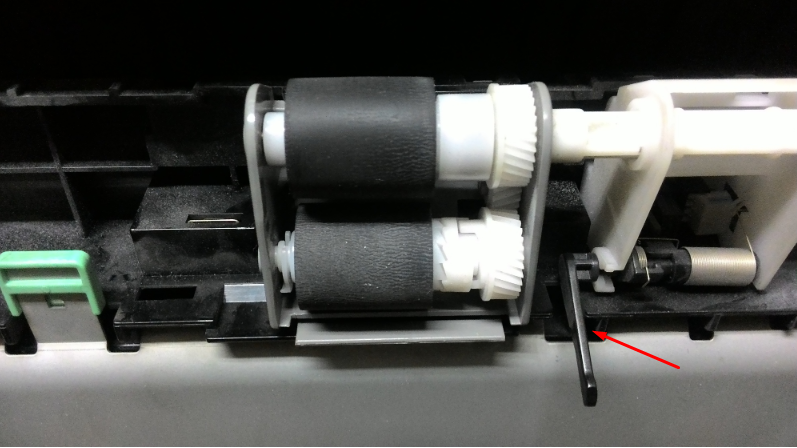

Если это не помогло и принтер упорно сообщает о том что в лотке нет бумаги проверяем не сломан ли флажок датчика наличия бумаги. Для этого извлекаем полностью нижний лоток, переворачиваем МФУ на один из боком и смотрим вот на этот флажок.

Он может сломаться, либо застрять в приводном валу такое бывает когда вытаскивают застрявшею бумагу, так же с него может слететь пружинка. Если есть неисправности исправляем их, после этого МФУ должно начать работать с вероятностью 95%. Если настройки правильные, флажок на месте но МФУ все равно не печатает то причина в другом. Если у Вас есть другой способ исправить эту ошибку обязательно поделитесь им.

Модератор: vetal

- Вложения

-

-

Foont

- Добрался до абсорбера

-

![]()

![]() Goldwater » Пн апр 19, 2021 4:11 pm

Goldwater » Пн апр 19, 2021 4:11 pm

Последний раз редактировалось Goldwater Пн апр 19, 2021 4:11 pm, всего редактировалось 1 раз.

-

Goldwater

- Избран тонером

-

![]()

![]() Foont » Пн апр 19, 2021 4:22 pm

Foont » Пн апр 19, 2021 4:22 pm

Goldwater писал(а):Явный недочинизм механизма подъёма лотка. Либо лифт, либо шестерня.

имеете в виду, что проблема изначально не только в сломанной оси? ошибку как на фото, выдавал и до замены направляющей.

-

Foont

- Добрался до абсорбера

-

![]()

![]() Foont » Пн апр 19, 2021 4:30 pm

Foont » Пн апр 19, 2021 4:30 pm

-

Foont

- Добрался до абсорбера

-

![]()

![]() Foont » Вт апр 20, 2021 12:45 pm

Foont » Вт апр 20, 2021 12:45 pm

-

Foont

- Добрался до абсорбера

-

![]()

-

- Kyocera FS-1120d индикатор «Нет бумаги»

vs-dos в форуме Принтеры, МФУ, факсы, копиры формата A4

- 11

- 14580

СТРОНЦИЙ

Вт ноя 02, 2021 2:24 pm

- Kyocera FS-1120d индикатор «Нет бумаги»

-

- [SCANNER ERROR] Lamp Error Kyocera FS-1016

мастерчип в форуме Принтеры, МФУ, факсы, копиры формата A4

- 3

- 6436

Усатый Полосатый

Вс окт 28, 2018 11:08 pm

- [SCANNER ERROR] Lamp Error Kyocera FS-1016

-

- Kyocera 1035 «бледная» печать

srMax в форуме Принтеры, МФУ, факсы, копиры формата A4

- 2

- 13544

srMax

Пт янв 23, 2015 2:49 pm

- Kyocera 1035 «бледная» печать

-

- Taskalfa 180 ошибка «Е» и «Встряхните картр. с тонером»

manik.76 в форуме Принтеры, МФУ, копиры формата A3

- 3

- 9189

dviz

Пн фев 20, 2017 1:35 pm

- Taskalfa 180 ошибка «Е» и «Встряхните картр. с тонером»

-

- Стирание вала ведущей шестерни в «печке» Kyocera M2035dn

Грецкий орех в форуме Принтеры, МФУ, факсы, копиры формата A4

- 12

- 2902

СТРОНЦИЙ

Пн дек 13, 2021 3:35 pm

- Стирание вала ведущей шестерни в «печке» Kyocera M2035dn

Вернуться в Принтеры, МФУ, факсы, копиры формата A4

Кто сейчас на форуме

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 131

Иногда ошибка звучит по-другому, «добавьте бумагу в универсальный лоток», но смысл один. Симптом «проблемы» прост. На компьютерах под управлением Windows 10 при попытке отправить на печать любой документ на МФУ, Kyocera выдаёт ошибку. На табло надпись — «вставьте бумагу в универсальный лоток». При этом есть возможность указать другой лоток с бумагой, и тогда документ распечатается, но не бегать же к нему постоянно?

По какой-то причине матёрые приходящие админы в некоторых организациях никак не могут победить эту горе-проблемку. А дело тут просто в источнике бумаги. Дело в том, что универсальный лоток (верхний) у Kyocera потому и универсальный, что способен жрать любую бумагу. Будь то открытки, картон или любой нестандартный размер — все эти форматы Kyocera будет печатать с универсального лотка. А возникающая ошибка лишь говорит нам о том, что с компа на мфу отправлена задача напечатать документ нестандартного размера.

Иногда всё очень просто — например при печате из Word секретарша просто не замечает размер бумаги, что там указан не А4, а, скажем, Letter (письмо). Но чаще всего там стоит верный формат, но Kyocera всё равно пишет «Вставьте бумагу в универсальный лоток».

Решение

Нужно вычислить, в каком именно месте МФУ чётко указано расположение лотка для бумаги, а так же является ли проблема общей, либо такая печать идёт лишь с одного компа.

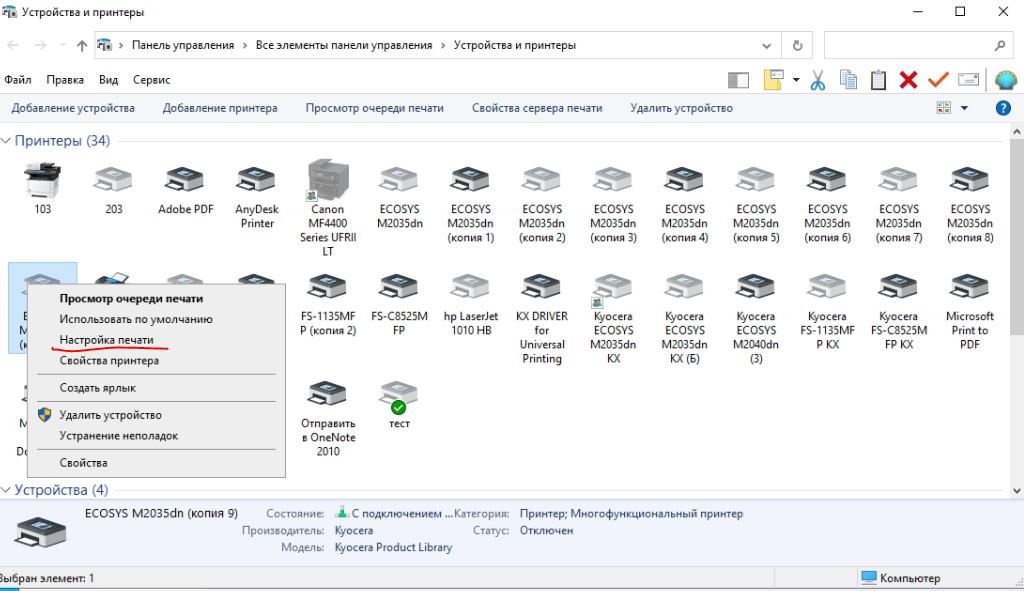

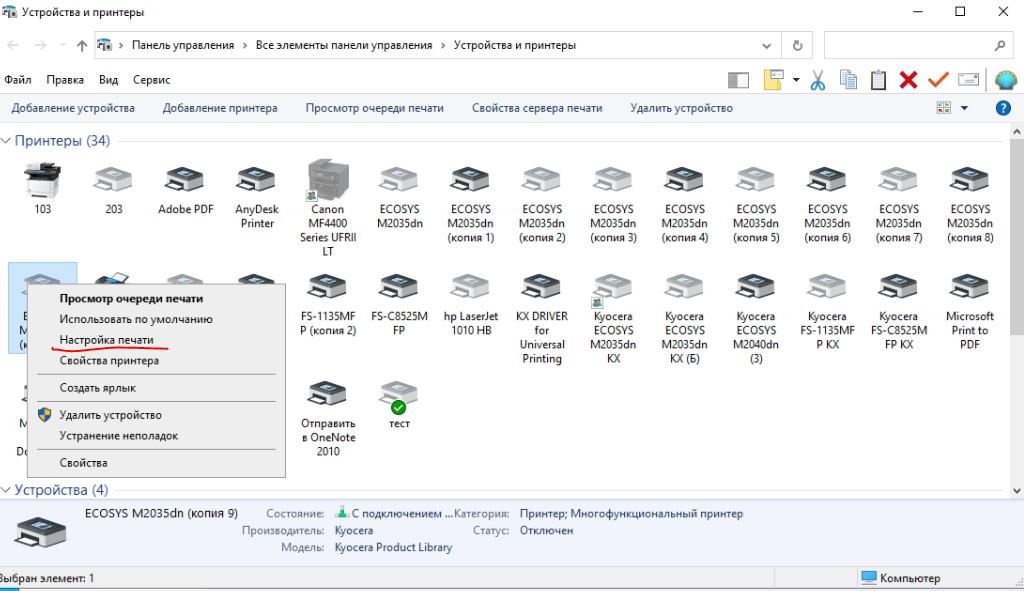

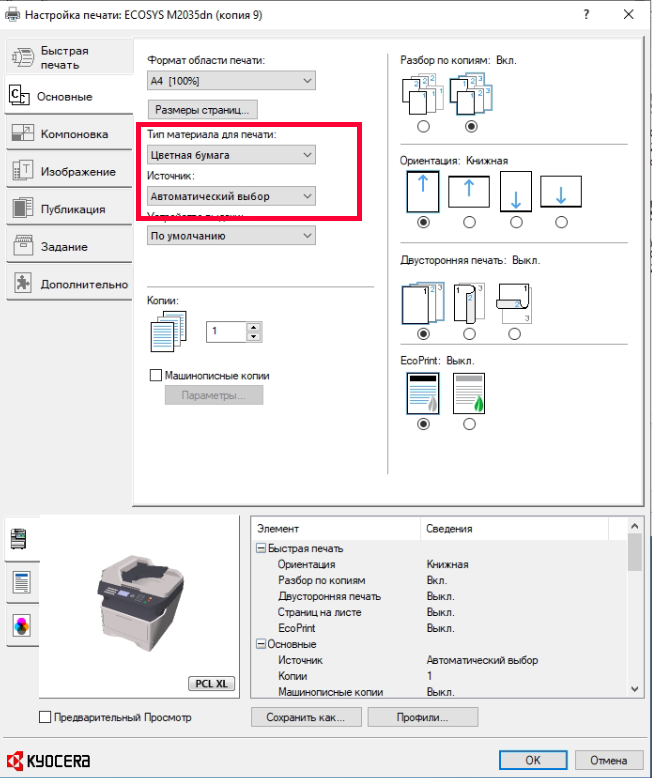

Если kyocera пишет ошибку «Вставьте бумагу в универсальный лоток» только с некоторых АРМ — дело в настройках на них. Первым делом у них следует проверить настройки печати. Для этого идём в панель управления — устройства и принтеры, правый тык на нужной мфу — настройка печати.

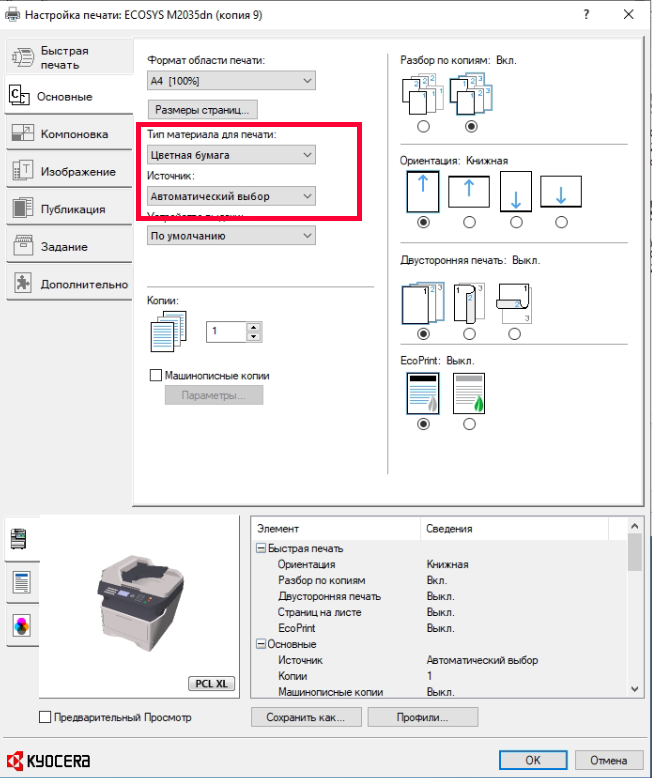

В первом же окне, на вкладке «основные» нужно убедиться в двух пунктах.

1. Тип материала для печати — должен быть Обычным, а не цветной бумагой и тд.

2. В качестве источника бумаги по-умолчанию не установлен универсальный лоток.

Обычно, на этом всё и заканчивается. Неизвестно почему, но во время штатной установки на некоторые компы драйвер Kyocera KX выставляет там левую бумагу.

Если же проблема наблюдается у любой машины, отправляющей на данную мфу задания по печати — нужно смотреть в конфигурацию самой Kyocera. Для этого идём в веб-часть мфу по её Ip адресу. Быстро узнать IP можно прям с Kyocera, выбрав Системное меню — печать отчёта — строка состояния. Логин и пароль по умолчанию разнятся у разных моделей, у 1135 это admin00, у 2035 — Admin.

Нас интересует пункт настройки устройства — бумага/подача/вывод. Проверьте что для первой касеты установлен тип материала обычный. Такой подвох вам скорее всего оставил бывший админ, либо какие-то шаловливые ручки. Верните настройки на свои места и бухгалтерии перестанут бегать к мфу, а вам скорее всего подарят пивасик.

Выдуманная проблема типа «вставьте бумагу в универсальный лоток» решена.

- Code: 0030

- Description: FAX PWB system error The FAX process can not be continued due to the malfunction of the FAXPWB. *Only 4in1 models detect

- Remedy: FAX PWB 1. Unplug the power cord from the wall outlet, and reinstall the FAX controller PWB, and then plug the power cord and turn power on. 2. Reinstall the FAX firmware. 3. Replace the FAX PWB.

- Code: 0070

- Description: FAX PWB incompatible detection error In the initial communication with the FAX control PWB, any normal communication command is not transmitted. *Only 4in1 models detect

- Remedy: FAX PWB 1. Install the FAX system designed for the model. 2. Reinstall the FAX firmware.

- Code: 0100

- Description: Backup memory device error Outputs an abnormal status from the flash memory.

- Remedy: Flash memory (Main/Engine PWB) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Check that the connectors on the Main/ Engine PWB are properly connected, and if not, re-connect them. 3. Replace the Main/Engine PWB.

- Code: 0120

- Description: MAC address data error In case MAC address is invalid data

- Remedy: Flash memory (Main/Engine PWB) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Check the MAC address on the network status page. 3. Replace the Main/Engine PWB.

- Code: 0130

- Description: Backup memory read/write error (Main/Engine PWB) Read/write to the NAND memory can not be executed.

- Remedy: Flash memory (Main/Engine PWB) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Check that the connectors on the Main/ Engine PWB are properly connected, and if not, re-connect them. 3. Replace the Main/Engine PWB.

- Code: 0140

- Description: Backup memory data error (Main/Engine PWB) At power up, the data that was read from the NAND memory has been determined to be a error.

- Remedy: Flash memory (Main/Engine PWB) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Execute U021 initialize memory. 3. Replace the Main/Engine PWB.

- Code: 0150

- Description: EEPROM read/write error (Main/Engine PWB) 1. No response is issued from the device in reading/ writing for 5 ms or more and this problem is repeated 5 times successively. 2. Mismatch of reading data from two locations occurs 8 times successively. 3. Mismatch between writing data and reading data occurs 8 times successively.

- Remedy: EEPROM (Main/ Engine PWB) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Check that the EEPROM is peroperly installed on the Main/Engine PWB and if not, reinstall it. 3. Replace the Main/Engine PWB. 4. Check the EEPROM and if it is damaged, contact the service support.

- Code: 0160

- Description: EEPROM data error (Main/ Engine PWB) Reading data from EEPROM is detected abnormal.

- Remedy: EEPROM (Main/ Engine PWB) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Execute U021 initialize memory. 3. If the EEPROM data are currupted, contact the service support.

- Code: 0170

- Description: Billing counting error Mismatch between the value of the Main/Engine PWB and EEPROM, in one of the value of billing counter, life counter, or scanner counter.

- Remedy: EEPROM (Main/ Engine PWB) 1. Check that the EEPROM installed in the Main/Engine PWB is correct and, if not, install the correct EEPROM for the model. 2. Replace the Main/Engine PWB. 3. If the EEPROM data are currupted, contact the service support.

- Code: 0180

- Description: Machine number mismatch When the power is turned on, the machine number does not match the one stored in the Main/Engine PWB.

- Remedy: EEPROM (Main/ Engine PWB) 1. Check that the EEPROM installed in the Main/Engine PWB is correct and, if not, install the correct EEPROM for the model. 2. Confirm the serial number data for the Main/Engine PWB by using U004. If the mutually different machine number data between «Machine No. (Main)» and «Machine No. (Eng)» is displayed, or if there is a difference between the actual machine number and the number of «Machine No. (Eng)», install the correct EEPROM, and then execute U004.

- Code: 0190

- Description: Backup memory device error (Main/Engine PWB) At power up, read/write data from FRAM can not be performed. (retry: 3times)

- Remedy: FRAM (Main/ Engine PWB) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Check that the connectors on the Main/ Engine PWB are properly connected, and if not, re-connect them. 3. Replace the Main/Engine PWB.

- Code: 0360

- Description: Communication error between the engine ASIC During the readback data checked after data transmission, the checksum error or the video signal is not inverted. (failed 10 consecutive times)

- Remedy: Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 0640

- Description: Hard disk (SSD) error During the file access after Ready, the I/O error of SSD is detected. (SSD format error after rebooting. For example, System initialization, Sanitization, Encrypted format when installing security kit.)

- Remedy: SSD (optional HD- 6/7) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Unplug the power cord from the wall outlet, and reinstall the HD-6/7 (SSD). 3. Check that the connection between KUIO connector on the Main/Engine PWB and HD-6/7 (SSD) is proper, and if not, re-connect them. 4. Initialize the HD-6/7 (SSD). 5. Replace the Main/Engine PWB.

- Code: 0800

- Description: Image formation problems The printing sequence JAM (J010X) is detected for 2 consecutive times.

- Remedy: Main/Engine PWB 1. Check if the problem is a printing operation error detection in a particular file, and if it is possible to obtain the reproduction of phenomena by the identification of the job that detected the error, take the job log. 2. If the problem occurs in unspecified job, check the connectors on the Main/ Engine PWB, and reattach it. 3. Replace the Main/Engine PWB.

- Code: 0830

- Description: FAX PWB flash program area checksum error The program stored in the flash memory on the FAX control PWB is broken and can not be executed. *Only 4in1 models dete

- Remedy: FAX firmware 1. Reinstall the FAX firmware.

FAX PWB 1. Unplug the power cord from the wall outlet, and reinstall the FAX controller PWB, and then plug the power cord and turn power on. 2. Check that the connection between KUIO connector on the Main/Engine PWB and Fax PWB is proper, and if not, re-connect them. 3. Execute [Initializing] by U600. 4. Replace the FAX PWB.

- Code: 0840

- Description: Faults of RTC Check at power up. The RTC setting has reverted to a previous state. The machine has not been powered for 5 years (compared to the settings stored periodically in the EEPROM). The RTC setting is older than 00:01 on January 1, 2000. Checked periodically (at every 5 minutes) after power-up. The RTC setting has reverted to a state older than the last time it was checked. 10 minutes have been passed since the previous check.

- Remedy: Settings of RTC 1. Execute Date Setting using the system menu.

Backup battery (Main/Engine PWB) 1. Check if the backup battery on the Main/ Engine PWB is not short-circuited. 2. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. If the same service call error is displayed, replace the backup battery

Main/Engine PWB 1. If the communication error (due to a noise, etc.) is present with the RTC on the Main/Engine PWB, check that the PWB is properly grounded or secured by screws. 2. Replace the Main/Engine PWB.

- Code: 0870

- Description: FAX PWB to Main/Engine PWB image data transfer error High-capacity data transfer between the FAX PWB and the Main/Engine PWB was not normally performed even if the data transfer was retried the specified times. *Only 4in1 models detect

- Remedy: FAX PWB 1. Unplug the power cord from the wall outlet, and reinstall the FAX controller PWB, and then plug the power cord and turn power on. 2. Check that the connection between KUIO connector on the Main/Engine PWB and Fax PWB is proper, and if not, re-connect them. 3. Replace the FAX PWB.

Main/Engine PWB 1. Replace the Main/Engine PWB.

- Code: 0920

- Description: Fax file system error The backup data is not retained for file system abnormality of the flash memory of the FAX PWB. *Only 4in1 models detect

- Remedy: FAX PWB 1. Execute [Initializing] by U600. 2. Reinstall the FAX firmware. 3. Unplug the power cord from the wall outlet, and reinstall the FAX controller PWB, and then plug the power cord and turn power on. 4. Check that the connection between KUIO connector on the Main/Engine PWB and Fax PWB is proper, and if not, re-connect them. 5. Replace the FAX PWB.

- Code: 1010

- Description: Lift motor error (main unit) The following states have been detected 5 times in succession. The lift motor overcurrent is detected for 80 ms. After the cassette is installed, the upper limit detection sensor does not turn ON within 10 s. During printing, after the upper limit detection sensor detects off, and 1 s after ascending control, and the upper limit detection sensor does not detect on. The upper limit detection sensor does not turn off within 5 s after descending control.

- Remedy: Bottom plate 1. Check to see if the bottom plate can move smoothly and repair or replace it if any problem is found.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. If a wire is pinched by other component, or has defect conduction, replace it. Lift motor and Engine relay PWB (YC25) Engine relay PWB (YC1) and Main/Engine PWB (YC4) Llift sensor and Engine relay PWB

Drive transmission system for the lift motor 1. Check if the gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Check broken gears and replace if any.

Lift motor Replace the lift motor.

Lift sensor (upper limit detection sensor) 1. Check if the actuator of the lift sensor can be turned ON/OFF to suit the rise of the cassette bottom plate. 2. Replace the lift sensor

Engine relay PWB 1. Replace the engine relay PWB.

Main/Engine PWB 1. Replace the Main/Engine PWB.

- Code: 1020

- Description: PF lift motor error (PF1) The following states have been detected 5 times in succession. The lift motor overcurrent is detected for 200 ms. After the cassette is installed, the upper limit detection sensor does not turn ON within 10 s. During printing, after the upper limit detection sensor detects off, and 1 s after ascending control, and the upper limit detection sensor does not detect on. The upper limit detection sensor does not turn off within 5 s after descending control.

- Remedy: Bottom plate Check to see if the bottom plate can move smoothly and repair or replace it if any problem is found.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. If a wire is pinched by other component, or has defect conduction, replace it. PF lift motor and PF main PWB (YC7) Llift sensor and PF main PWB (YC7) PF main PWB and Engine relay PWB (YC19)

Drive transmission system for the lift motor 1. Check if the gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Check broken gears and replace if any.

PF lift motor Replace the PF lift motor 1.

PF lift sensor (upper limit detection sensor) 1. Check if the actuator of the PF lift sensor can be turned ON/OFF to suit the rise of the cassette bottom plate. 2. Replace the PF lift sensor.

PF main PWB Replace the PF main PWB.

Engine relay PWB Replace the engine relay PWB.

- Code: 1030

- Description: PF lift motor error (PF2) The following states have been detected 5 times in succession. The lift motor overcurrent is detected for 200 ms. After the cassette is installed, the upper limit detection sensor does not turn ON within 10 s. During printing, after the upper limit detection sensor detects off, and 1 s after ascending control, and the upper limit detection sensor does not detect on. The upper limit detection sensor does not turn off within 5 s after descending control.

- Remedy: Bottom plate Check to see if the bottom plate can move smoothly and repair or replace it if any problem is found.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. If a wire is pinched by other component, or has defect conduction, replace it. PF lift motor and PF main PWB (YC7) Llift sensor and PF main PWB (YC7) PF main PWB and Engine relay PWB (YC19)

Drive transmission system for the lift motor 1. Check if the gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Check broken gears and replace if any.

PF lift motor Replace the PF lift motor 2.

PF lift sensor (upper limit detection sensor) 1. Check if the actuator of the PF lift sensor can be turned ON/OFF to suit the rise of the cassette bottom plate. 2. Replace the PF lift sensor.

PF main PWB Replace the PF main PWB.

Engine relay PWB Replace the engine relay PWB.

- Code: 1040

- Description: PF lift motor error (PF3) The following states have been detected 5 times in succession. The lift motor overcurrent is detected for 200 ms. After the cassette is installed, the upper limit detection sensor does not turn ON within 10 s. During printing, after the upper limit detection sensor detects off, and 1 s after ascending control, and the upper limit detection sensor does not detect on. The upper limit detection sensor does not turn off within 5 s after descending control.

- Remedy: Bottom plate Check to see if the bottom plate can move smoothly and repair or replace it if any problem is found.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. If a wire is pinched by other component, or has defect conduction, replace it. PF lift motor and PF main PWB (YC7) Llift sensor and PF main PWB (YC7) PF main PWB and Engine relay PWB (YC19)

Drive transmission system for the lift motor 1. Check if the gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Check broken gears and replace if any.

PF lift motor Replace the PF lift motor.

PF lift sensor (upper limit detection sensor) 1. Check if the actuator of the PF lift sensor can be turned ON/OFF to suit the rise of the cassette bottom plate. 2. Replace the PF lift sensor.

PF main PWB Replace the PF main PWB.

Engine relay PWB Replace the engine relay PWB.

- Code: 1810

- Description: Paper feeder communication error (first cassette) A communication error from paper feeder is detected 10 times in succession.

- Remedy: Paper feeder 1 Check the wiring connection status with the main unit, and if necessary, reconnecting it.

PF1 main PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. PF1 main PWB (YC3 and Engine relay PWB (YC19) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Reinstall the PF firmware. 4. Replace the PF main PWB. (Refer to the service manual for the paper feeder).

Engine relay PWB 1. Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 1820

- Description: Paper feeder communication error (second cassette) A communication error from paper feeder is detected 10 times in succession.

- Remedy: Paper feeder 2 Check the wiring connection status with PF1, and if necessary, reconnect it.

PF2 main PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. PF1 main PWB (YC3)and PF2 main PWB (YC5,4) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Reinstall the PF firmware. 4. Replace the PF2 main PWB.

PF1 main PWB Replace the PF1 main PWB.

- Code: 1830

- Description: Paper feeder communication error (third cassette) A communication error from paper feeder is detected 10 times in succession.

- Remedy: Paper feeder 3 Check the wiring connection status with PF2, and if necessary, reconnect it.

PF3 main PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. PF2 main PWB (YC3 and PF3 main PWB (YC5,4) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Reinstall the PF firmware. 4. Replace the PF3 main PWB.

PF2 main PWB Replace the PF2 main PWB.

- Code: 1900

- Description: Paper feeder 1 EEPROM error (first cassette) When writing the data, read and write data does not match 4 times in succession.

- Remedy: PF1 main PWB (EEPROM) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Confirm that the wiring connector to the main unit is firmly connected, and if necessary, connect the connector all the way in. 3. Replace the PF1 main PWB.

- Code: 1910

- Description: Paper feeder 2 EEPROM error (second cassette) When writing the data, read and write data does not match 4 times in succession.

- Remedy: PF2 main PWB (EEPROM) 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Confirm that the wiring connector with the PF1 is firmly connected, and if necessary, connect the connector all the way in. 3. Replace the PF2 main PWB.

- Code: 1920

- Description: Paper feeder 3 EEPROM error (third cassette) When writing the data, read and write data does not match 4 times in succession.

- Remedy: PF3 main PWB 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Confirm that the wiring connector with the PF2 is firmly connected, and if necessary, connect the connector all the way in. 3. Replace the PF3 main PWB.

- Code: 2101

- Description: Developer motor steadystate error (C,M,Y) After motor is stabilized, the stable signal is turned OFF for continuous 2 s.

- Remedy: Developer unit 1. Check that the developer roller can be rotated by hand, and if it is locked, replace the developer unit.

Developer motor 1. Check if the couplings and gears rotate smoothly, and if necessary replace them. 2. Reinsert the connector. 3. Check continuity within the connector wire. If none, replace the wire. Developer motor and Engine relay PWB (YC12) Engine relay PWB (YC1) and Main/ Engine PWB (YC4) 4. Replace the developer motor

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 2111

- Description: Developer motor startup error (C,M,Y) After the motor starting, the stable signal is not turned ON within 3 s.

- Remedy: Developer unit 1. Check that the developer roller can be rotated by hand, and if it is locked, replace the developer unit.

Developer motor 1. Check if the couplings and gears rotate smoothly, and if necessary replace them. 2. Reinsert the connector. 3. Check continuity within the connector wire. If none, replace the wire. Developer motor and Engine relay PWB (YC12) Engine relay PWB (YC1) and Main/ Engine PWB (YC4) 4. Replace the developer motor

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 2201

- Description: Drum motor CY steadystate error After motor is stabilized, the stable signal is turned OFF for continuous 2 s.

- Remedy: Drum unit C or Drum unit Y Check that the drum can be rotated by hand, and if it is locked, replace the drum unit C or drum unit Y.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. Drum motor CY and Engine relay PWB (YC13) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Drive transmission system for the drum motor CY 1. Check if the couplings and gears rotate smoothly, and if not, clean or grease the gears. 2. Check broken couplings and gears, and replace if any.

Drum motor CY Replace the drum motor CY.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 2202

- Description: Drum motor KM steadystate error After motor is stabilized, the stable signal is turned OFF for continuous 2 s.

- Remedy: Drum unit K or Drum unit M Check that the drum can be rotated by hand, and if it is locked, replace the drum unit K or drum unit M.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. Drum motor KM and Engine relay PWB (YC13) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Drive transmission system for the drum motor KM 1. Check if the couplings and gears rotate smoothly, and if not, clean or grease the gears. 2. Check broken couplings and gears, and replace if any.

Drum motor KM Replace the drum motor KM.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 2211

- Description: Drum motor CY startup error After the motor starting, the stable signal is not turned ON within 3 s.

- Remedy: Drum unit C or Drum unit Y Check that the drum can be rotated by hand, and if it is locked, replace the drum unit C or drum unit Y.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. Drum motor CY and Engine relay PWB (YC13) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Drive transmission system for the drum motor CY 1. Check if the couplings and gears rotate smoothly, and if not, clean or grease the gears. 2. Check broken couplings and gears, and replace if any.

Drum motor CY Replace the drum motor CY.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 2212

- Description: Drum motor KM startup error After the motor starting, the stable signal is not turned ON within 3 s.

- Remedy: Drum unit K or Drum unit M Check that the drum can be rotated by hand, and if it is locked, replace the drum unit K or drum unit M.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. Drum motor KM and Engine relay PWB (YC13) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Drive transmission system for the drum motor KM 1. Check if the couplings and gears rotate smoothly, and if not, clean or grease the gears. 2. Check broken couplings and gears, and replace if any.

Drum motor KM Replace the drum motor KM.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 2500

- Description: Paper feed motor error After the motor starting, the stable signal is not turned ON within 3 s. After motor is stabilized, the stable signal is turned OFF for continuous 2 s.

- Remedy: Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. Paper feed motor and Engine relay PWB (YC15) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Drive transmission system for the paper feed motor 1. Check if the rollers and gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Replace the gears, if damaged.

Paper feed motor Replace the paper feed motor.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 2600

- Description: PF drive motor 1 error (PF1) During the motor drive, the stable signal is not turned on for continuous 5 s.

- Remedy: Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. PF drive motor 1 and PF main PWB (YC6)

Drive transmission system for the PF drive motor 1. Check if the rollers and gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Replace the gears, if damaged.

PF drive motor Replace the PF drive motor 1.

PF main PWB Replace the PF main PWB.

- Code: 2610

- Description: PF drive motor 2 error (PF2) During the motor drive, the stable signal is not turned on for continuous 5 s.

- Remedy: Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. PF drive motor 2 and PF main PWB (YC6)

Drive transmission system for the PF drive motor 1. Check if the rollers and gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Replace the gears, if damaged.

PF drive motor Replace the PF drive motor 2.

PF main PWB Replace the PF main PWB.

- Code: 2620

- Description: PF drive motor 3 error (PF3) During the motor drive, the stable signal is not turned on for continuous 5 s.

- Remedy: Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. PF drive motor 3 and PF main PWB (YC6)

Drive transmission system for the PF drive motor 1. Check if the rollers and gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Replace the gears, if damaged.

PF drive motor Replace the PF drive motor 3.

PF main PWB Replace the PF main PWB.

- Code: 2760

- Description: Primary transfer belt motor startup error After the motor starting, the stable signal is not turned ON within 3 s.

- Remedy: Primary transfer unit 1. Check that the belt can be rotated by hand, and if it is locked, get rid of the factor. 2. Replace the primary transfer unit.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. Transfer belt motor and Engine relay PWB (YC14) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Drive transmission system for the primary transfer belt motor 1. Check if the rollers and gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Replace the gears, if damaged.

Primary transfer belt motor Replace the primary transfer belt motor.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 2820

- Description: Primary transfer belt motor steady-state error After motor is stabilized, the stable signal is turned OFF for continuous 2 s.

- Remedy: Primary transfer unit 1. Check that the belt can be rotated by hand, and if it is locked, check if foreign objects such as jammed paper, and if jammed, get rid of it. 2. Replace the primary transfer unit.

Defective connector cable or poor contact in the connector 1. Reinsert the connector. 2. Check continuity within the connector wire. If none, replace the wire. Transfer belt motor and Engine relay PWB (YC14) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Drive transmission system for the primary transfer belt motor 1. Check if the rollers and gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Replace the gears, if damaged.

Primary transfer belt motor Replace the primary transfer belt motor.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 3100

- Description: Scanner carriage error When turning the power on, or when the reading of the original document by table or DP scanning has completed, the home position sensor is not turned off, even if the home position sensor is on and the scanner carriage moves to the scanning direction. Or, the home position sensor does not turn on, even if the home position sensor is in off and the scanner carriage move to the return direction.

- Remedy: Image scanner motor 1. Move the scanner by hand to check whether it smoothly moves, and if necessary, remedy it. 2. Check that the scanner drive belt is not disengaged, and if necessary, remedy it. 3. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Image scanner motor and Main/Engine PWB (YC17) 4. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 5. Replace the image scanner motor.

Home position sensor 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Home position sensor and CCD PWB (YC3) CCD PWB (YC1) and Main/Engine PWB (YC2014) 3. Replace the home position sensor.

CCD PWB Replace the scanner carriage and execute the U411.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 3200

- Description: LED lamp error The white standard data obtained when the lamp is turned on at the time of an initialization is lower than the rated value.

- Remedy: LED PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LED PWB and CCD PWB (YC2) CCD PWB (YC1) and Main/Engine PWB (YC2014)

Mirror Replace the image scanner unit and execute U411, if the mirror is dropped off by drop shock.

CCD PWB Replace the scanner carriage and execute the U411.

Main/Engine PWB Replace the Main/Engine PWB.

- Code: 3500

- Description: Communication error between scanner ASIC (MFP model only) A communication error is detected. (Read back values are different.)

- Remedy: CCD PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. CCD PWB (YC1) and Main/Engine PWB (YC2014) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the scanner carriage and execute the U411.

Main/Engine PWB 1. Upgrade the scanner firmware to the latest version. 2. Replace the Main/Engine PWB.

- Code: 4001

- Description: Polygon motor (Black, Magenta) startup error After the polygon motor starting, the motor stable signal is not turned ON after 6 s.

- Remedy: Polygon motor (Black, Magenta) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2016) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 4002

- Description: Polygon motor (Cyan, Yellow) startup error After the polygon motor starting, the motor stable signal is not turned ON after 6 s.

- Remedy: Polygon motor (Cyan, Yellow) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2017) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 4011

- Description: Polygon motor (Black, Magenta) steady error After the polygon motor stabilization, the motor stable signal is turned OFF for consecutive 6 s.

- Remedy: Polygon motor (Black, Magenta) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2016) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 4012

- Description: Polygon motor (Cyan, Yellow) steady error After the polygon motor stabilization, the motor stable signal is turned OFF for consecutive 6 s.

- Remedy: Polygon motor (Cyan, Yellow) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2017) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 4101

- Description: Laser BD (Black) error The laser can not be received for 1 s, after the Black laser emission starts.

- Remedy: LSU (Black,Magenta) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2016) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check both main and engine firmware, and upgrade to the latest version, if necessary. 2. Replace the Main/Engine PWB.

- Code: 4102

- Description: Laser BD (Cyan) error The laser can not be received for 1 s, after the Cyan laser emission starts.

- Remedy: LSU (Cyan, Yellow) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2017) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check both main and engine firmware, and upgrade to the latest version, if necessary. 2. Replace the Main/Engine PWB.

- Code: 4103

- Description: Laser BD (Magenta) error The laser can not be received for 1 s, after the Magenta laser emission starts.

- Remedy: LSU (Black,Magenta) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2016) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check both main and engine firmware, and upgrade to the latest version, if necessary. 2. Replace the Main/Engine PWB.

- Code: 4104

- Description: Laser BD (Yellow) error The laser can not be received for 1 s, after the Yellow laser emission starts.

- Remedy: LSU (Cyan, Yellow) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2017) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check both main and engine firmware, and upgrade to the latest version, if necessary. 2. Replace the Main/Engine PWB.

- Code: 4201

- Description: Laser BD (Black) steadystate error During the polygon motor steady rotation, the BD signal of Black is not detected.

- Remedy: LSU (Black,Magenta) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2016) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check both main and engine firmware, and upgrade to the latest version, if necessary. 2. Replace the Main/Engine PWB.

- Code: 4202

- Description: Laser BD (Cyan) steadystate error During the polygon motor steady rotation, the BD signal of Cyan is not detected.

- Remedy: LSU (Cyan,Yellow) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2017) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check both main and engine firmware, and upgrade to the latest version, if necessary. 2. Replace the Main/Engine PWB.

- Code: 4203

- Description: Laser BD (Magenta) steadystate error During the polygon motor steady rotation, the BD signal of Magenta is not detected.

- Remedy: LSU (Black,Magenta) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2016) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check both main and engine firmware, and upgrade to the latest version, if necessary. 2. Replace the Main/Engine PWB.

- Code: 4204

- Description: Laser BD (Yellow) steadystate error During the polygon motor steady rotation, the BD signal of Yellow is not detected.

- Remedy: LSU (Cyan,Yellow) 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. LSU and Main/Engine PBW (YC2017) 2. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 3. Replace the LSU.

Main/Engine PWB 1. Check both main and engine firmware, and upgrade to the latest version, if necessary. 2. Replace the Main/Engine PWB.

- Code: 4600

- Description: LSU cleaning motor error During driving the LSU cleaning motor, an over-current is detected for 5 s successively

- Remedy: LSU cleaning spiral 1. Execute [LSU cleaning] using [Adjustment/ Maintenance] of the system menu. 2. Check that the drive gear and cleaning spiral can rotate and they are not unusually loaded, and if necessary, clean and grease.

LSU cleaning motor 1. Confirm that the LSU cleaning motor has been firmly attached. 2. Replace the LSU cleaning motor.

Engine relay PWB 1. Reconnect the connector if its connection is loose. 2. If a wire is pinched by other component, or has defect conduction, replace it. LSU cleaning motor and Engine relay PWB (YC26) 3. Replace the engine relay PWB.

- Code: 4700

- Description: VIDEO_ASIC device error Communication with the video ASIC has failed 5 times successively. After writing to VIDEO ASIC, the error that the reading value from same address does not match occurs 8 times successively.

- Remedy: Main/Engine PWB 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Check that the connectors on the Main/ Engine PWB are properly connected, and if not, re-connect them. 3. Replace the Main/Engine PWB.

- Code: 6000

- Description: Broken fuser main heater wire During the warming up, the temperature detected by the center thermistor does not reach 100 °C/212.0 °F for 20 s. During the warming up, the temperature detected by the center thermistor does not reach the stable display temperature for 30 s successively, after it reach to 100 °C/212.0 °F.

- Remedy: Fuser unit 1. Check there is no paper jam. 2. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 3. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 4. If the fuser heater is not turned on (broken thermostat wire), replace the fuser unit.

Power source PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Power source PWB (YC105) and Main/ Engine PWB (YC20) 2. Replace the power source PWB.

Eject PWB Replace the eject PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 6020

- Description: Abnormally high fuser center thermistor temperature The center thermistor detected the temperature exceeds 240 °C/464.0 °F. for 1 s successively.

- Remedy: Fuser unit 1. Check there is no paper jam. 2. Check if the fuser roller has foreign objects such as the toner contamination. 3. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 4. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 5. Replace the fuser unit.

Power source PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Power source PWB (YC105) and Main/ Engine PWB (YC20) 2. If the fuser heater is turned on at all times, replace the power source PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Check if the Main/Engine PWB is properly secured with screws. 3. Replace the Main/Engine PWB.

- Code: 6030

- Description: Broken fuser center thermistor wire During the edge thermistor detects more than 30 °C/86.0 °F, the center thermistor detects low temperature for 1.6 s.

- Remedy: Fuser unit 1. Check there is no paper jam. 2. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 3. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 4. Replace the fuser unit.

Eject PWB Replace the eject PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 6040

- Description: Fuser heater error (35 ppm models) Input value from the fuser center thermistor is abnormal for 1 s successively.

- Remedy: Fuser unit 1. Check there is no paper jam. 2. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 3. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 4. Replace the fuser unit.

Eject Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.PWB Replace the eject PWB.

- Code: 6050

- Description: Abnormally low fuser center thermistor temperature During the warming up and the printing, the center thermistor has detected less than 100 °C/212.0 °F. for 1 s successively.

- Remedy: Reduction of the power supply voltage 1. Check that no voltage drop of more than 10% of the rated is caused during printing. 2. If the power is overloaded, change the AC outlet that supplies power.

Fuser unit 1. Check there is no paper jam. 2. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 3. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 4. If the fuser heater is not turned on (broken thermostat wire), replace the fuser unit.

Power source PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Power source PWB (YC105) and Main/ Engine PWB (YC20) 2. Replace the power source PWB.

Eject PWB Replace the eject PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 6200

- Description: Fuser heater error (SUb heater: for 35ppm models) During the warming up, even if the main heater (sub heater for 35ppm models) is turned on for 30 s successively, the temperature detected by the edge thermistor does not reach 100 °C/212.0 °F. During the warming up, the temperature detected by the edge thermistor does not reach the stable display temperature, even if the main heater (sub heater for 35ppm models) is turned on for 30 s successively, after the temperature detected by the edge thermistor has reached to 100 °C/212.0 °F.

- Remedy: Fuser unit 1. Check there is no paper jam. 2. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 3. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 4. If the fuser sub-heater is not turned on (broken thermostat wire), replace the fuser unit.

Power source PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Power source PWB (YC105) and Main/ Engine PWB (YC20) 2. Replace the power source PWB.

Eject PWB Replace the eject PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 6220

- Description: Abnormally high fuser heater temperature The temperature detected by the edge thermistor exceeds 240 °C/464.0 °F for 1 s successively.

- Remedy: Fuser unit 1. Check there is no paper jam. 2. Check if the fuser roller has foreign objects such as the toner contamination. 3. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 4. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 5. Replace the fuser unit.

Power source PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Power source PWB (YC105) and Main/ Engine PWB (YC20) 2. If the fuser heater is turned on at all times, replace the power source PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Check if the Main/Engine PWB is properly secured with screws. 3. Replace the Main/Engine PWB.

- Code: 6230

- Description: Broken fuser edge thermistor wire Fuser edge thermistor detects low temperature for 1.6 s.

- Remedy: Fuser unit 1. Check there is no paper jam. 2. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 3. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 4. Replace the fuser unit.

Eject PWB Replace the eject PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 6250

- Description: Abnormally low fuser edge thermistor temperature During the warming up and the printing, the edge thermistor has detected less than 100 °C/212.0 °F for 1 s successively.

- Remedy: Reduction of the power supply voltage 1. Check that no voltage drop of more than 10% of the rated is caused during printing. 2. If the power is overloaded, change the AC outlet that supplies power.

Fuser unit 1. Check there is no paper jam. 2. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 3. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 4. If the fuser heater is not turned on (broken thermostat wire), replace the fuser unit.

Power source PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Power source PWB (YC105) and Main/ Engine PWB (YC20) 2. Replace the power source PWB.

Eject PWB Replace the eject PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 6400

- Description: Zero-cross signal error During the fuser heater on, and no detection the disconnection 24V, the zero-cross signal is not input for 1 s successively.

- Remedy: Power source PWB 1. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Power source PWB (YC105) and Main/ Engine PWB (YC20) 2. Replace the power source PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 6610

- Description: The fuser pressure release error The fuser release sensor does not turn on or off, after 30 s from starting pressurization or depressurization operation.

- Remedy: Fuser unit 1. Check there is no paper jam. 2. Check if the fuser pressure can be reduced by inverse rotation of the fuser gear by hand. 3. Check if the envelope sensor light is blocked out by the actuator during depressurization operation. 4. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser unit (Envelope sensor) and Eject PWB (YC2) Eject PWB (YC1) and Main/Engine PWB (YC11) 5. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 6. Replace the fuser unit.

Fuser motor 1. Check if the fuser motor is rotating. 2. When turning the power on, check if the fuser motor rotates reversely. 3. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Fuser motor and Engine relay PWB (YC20) 4. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 5. Replace the fuser motor.

Eject PWB Replace the eject PWB.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 6910

- Description: Engine firmware unexpected error The drum motor drive continued more than 60 minutes except during printing. (engine lock) The charge bias is turned off, during the developer bias is on. If the writing operation to the EEPROM is locked for 30 sec. Fuser temperature is abnormal, for more than a predetermined time.

- Remedy: Main/Engine PWB 1. Unplug the power cord from the wall outlet, and wait five seconds. Then plug the power cord and then turn on the power switch. 2. Check if the Main/Engine PWB is properly secured with screws. (Grounding check) 3. Check that the connectors on the Main/ Engine PWB are properly connected, and if not, re-connect them. 4. Check the engine firmware and upgrade to the latest version if necessary. 5. Replace the Main/Engine PWB.

- Code: 7001

- Description: Toner motor K error During driving the toner motor, an over-current detection signal is detected for 40 ms successively. When detected during warming up The message of «Shake the toner container (K)» is displayed. (exited by the opening and closing of the inner tray) Repeat the operation above, for three times. Four times or more, if an over-current detection signal is detected for 5 s successively, a service call error message appears.

- Remedy: Toner container Black 1. Check that the spiral of the toner container can be rotated by hand 2. Replace the toner container.

Drive transmission system for the toner motor 1. Check if the couplings and gears rotate smoothly, and if not, clean or grease the gears. 2. Check broken couplings and gears, and replace if any.

Defective connector cable or poor contact in the connector 1. Reconnect the connector if its connection is loose. 2. If a wire is pinched by other component, or has defect conduction, replace it. Toner motor and Engine relay PWB (YC18) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Toner motor 1. Check how the toner motor is attached. 2. Replace the toner motor.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7002

- Description: Toner motor C error During driving the toner motor, an over-current detection signal is detected for 40 ms successively. When detected during warming up The message of «Shake the toner container (C)» is displayed. (exited by the opening and closing of the inner tray) Repeat the operation above, for three times. Four times or more, if an over-current detection signal is detected for 5 s successively, a service call error message appears.

- Remedy: Toner container Cyan 1. Check that the spiral of the toner container can be rotated by hand 2. Replace the toner container.

Drive transmission system for the toner motor 1. Check if the couplings and gears rotate smoothly, and if not, clean or grease the gears. 2. Check broken couplings and gears, and replace if any.

Defective connector cable or poor contact in the connector 1. Reconnect the connector if its connection is loose. 2. If a wire is pinched by other component, or has defect conduction, replace it. Toner motor and Engine relay PWB (YC18) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Toner motor 1. Check how the toner motor is attached. 2. Replace the toner motor.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7003

- Description: Toner motor M error During driving the toner motor, an over-current detection signal is detected for 40 ms successively. When detected during warming up The message of «Shake the toner container (M)» is displayed. (exited by the opening and closing of the inner tray) Repeat the operation above, for three times. Four times or more, if an over-current detection signal is detected for 5 s successively, a service call error message appears.

- Remedy: Toner container Magenta 1. Check that the spiral of the toner container can be rotated by hand 2. Replace the toner container.

Drive transmission system for the toner motor 1. Check if the couplings and gears rotate smoothly, and if not, clean or grease the gears. 2. Check broken couplings and gears, and replace if any.

Defective connector cable or poor contact in the connector 1. Reconnect the connector if its connection is loose. 2. If a wire is pinched by other component, or has defect conduction, replace it. Toner motor and Engine relay PWB (YC18) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Toner motor 1. Check how the toner motor is attached. 2. Replace the toner motor.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7004

- Description: Toner motor Y error During driving the toner motor, an over-current detection signal is detected for 40 ms successively. When detected during warming up The message of «Shake the toner container (Y)» is displayed. (exited by the opening and closing of the inner tray) Repeat the operation above, for three times. Four times or more, if an over-current detection signal is detected for 5 s successively, a service call error message appears.

- Remedy: Toner container Yellow 1. Check that the spiral of the toner container can be rotated by hand 2. Replace the toner container.

Drive transmission system for the toner motor 1. Check if the gears rotate smoothly. If not, clean or grease the bushes and gears. 2. Check broken couplings and gears, and replace if any.

Defective connector cable or poor contact in the connector 1. Reconnect the connector if its connection is loose. 2. If a wire is pinched by other component, or has defect conduction, replace it. Toner motor and Engine relay PWB (YC18) Engine relay PWB (YC1) and Main/Engine PWB (YC4)

Toner motor 1. Check how the toner motor is attached. 2. Replace the toner motor.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7101

- Description: Toner sensor K error For a certain period of time, the sensor output value is less than 0.1V, or more than 3.2V.

- Remedy: Toner container Black 1. Check that the toner container has been properly installed, and if necessary, reinstall. 2. Check that the toner supply inlet of the toner container can be opened by the lever operation. 3. Replace the toner container.

Primary transfer unit 1. Check whether the toner supply inlet at the upper side of the unit opens by attaching the toner container. 2. Check whether the toner supply inlet at the lower side of the unit is open by the lever operation. 3. Check if toner is clogged in the toner supplying pass in the cleaning section. 4. Replace the primary transfer unit.

Developer unit (toner sensor) 1. Confirm that the connector of the developer unit is firmly connected, and if necessary, push the unit all the way in. Developer unit (toner sensor) and Drum relay PWB (YC6) Drum relay PWB (YC1) and Main/Engine PWB (YC15) 2. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 3. Check if the gears and spirals in the developer unit rotate smoothly. 4. Replace the developer unit.

Toner motor 1. Check that the toner motor is properly attached. 2. Check the couplings and gears can rotate or they are not unusually loaded, and if necessary, replace. 3. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Toner motor and Engine relay PWB (YC18) Engine relay PWB (YC1) and Main/Engine PWB (YC4) 4. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 5. Replace the toner motor.

Drum relay PWB Replace the drum relay PWB.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7102

- Description: Toner sensor C error For a certain period of time, the sensor output value is less than 0.1V, or more than 3.2V.

- Remedy: Toner container Cyan 1. Check that the toner container has been properly installed, and if necessary, reinstall. 2. Check that the toner supply inlet of the toner container can be opened by the lever operation. 3. Replace the toner container.

Primary transfer unit 1. Check whether the toner supply inlet at the upper side of the unit opens by attaching the toner container. 2. Check whether the toner supply inlet at the lower side of the unit is open by the lever operation. 3. Check if toner is clogged in the toner supplying pass in the cleaning section. 4. Replace the primary transfer unit.

Developer unit (toner sensor) 1. Confirm that the connector of the developer unit is firmly connected, and if necessary, push the unit all the way in. Developer unit (toner sensor) and Drum relay PWB (YC8) Drum relay PWB (YC1) and Main/Engine PWB (YC15) 2. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 3. Check if the gears and spirals in the developer unit rotate smoothly. 4. Replace the developer unit.

Toner motor 1. Check that the toner motor is properly attached. 2. Check the couplings and gears can rotate or they are not unusually loaded, and if necessary, replace. 3. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Toner motor and Engine relay PWB (YC18) Engine relay PWB (YC1) and Main/Engine PWB (YC4) 4. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 5. Replace the toner motor.

Drum relay PWB Replace the drum relay PWB.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7103

- Description: Toner sensor M error For a certain period of time, the sensor output value is less than 0.1V, or more than 3.2V.

- Remedy: Toner container Magenta 1. Check that the toner container has been properly installed, and if necessary, reinstall. 2. Check that the toner supply inlet of the toner container can be opened by the lever operation. 3. Replace the toner container.

Primary transfer unit 1. Check whether the toner supply inlet at the upper side of the unit opens by attaching the toner container. 2. Check whether the toner supply inlet at the lower side of the unit is open by the lever operation. 3. Check if toner is clogged in the toner supplying pass in the cleaning section. 4. Replace the primary transfer unit.

Developer unit (toner sensor) 1. Confirm that the connector of the developer unit is firmly connected, and if necessary, push the unit all the way in. Developer unit (toner sensor) and Drum relay PWB (YC7) Drum relay PWB (YC1) and Main/Engine PWB (YC15) 2. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 3. Check if the gears and spirals in the developer unit rotate smoothly. 4. Replace the developer unit.

Toner motor 1. Check that the toner motor is properly attached. 2. Check the couplings and gears can rotate or they are not unusually loaded, and if necessary, replace. 3. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Toner motor and Engine relay PWB (YC1) Engine relay PWB (YC1) and Main/Engine PWB (YC4) 4. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 5. Replace the toner motor.

Drum relay PWB Replace the drum relay PWB.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7104

- Description: Toner sensor Y error For a certain period of time, the sensor output value is less than 0.1V, or more than 3.2V.

- Remedy: Toner container Yellow 3. Check that the toner container has been properly installed, and if necessary, reinstall. 4. Check that the toner supply inlet of the toner container can be opened by the lever operation. 5. Replace the toner container.

Primary transfer unit 1. Check whether the toner supply inlet at the upper side of the unit opens by attaching the toner container. 2. Check whether the toner supply inlet at the lower side of the unit is open by the lever operation. 3. Check if toner is clogged in the toner supplying pass in the cleaning section. 4. Replace the primary transfer unit.

Developer unit (toner sensor) 1. Confirm that the connector of the developer unit is firmly connected, and if necessary, push the unit all the way in. Developer unit (toner sensor) and Drum relay PWB (YC9) Drum relay PWB (YC1) and Main/Engine PWB (YC4) 2. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 3. Check if the gears and spirals in the developer unit rotate smoothly. 4. Replace the developer unit.

Toner motor 1. Check that the toner motor is properly attached. 2. Check the couplings and gears can rotate or they are not unusually loaded, and if necessary, replace. 3. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. Toner motor and Engine relay PWB (YC18) Engine relay PWB (YC1) and Main/Engine PWB (YC4) 4. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 5. Replace the toner motor.

Drum relay PWB Replace the drum relay PWB.

Engine relay PWB Replace the engine relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7200

- Description: Broken inner thermistor wire (Developer) The sensor input sampling is greater than the reference value. (After detection, controlled at 25 °C/77.0 °F)

- Remedy: Developer unit K 1. Confirm that the connector of developer unit K is firmly connected, and if necessary, push the unit all the way in. Developer unit K (toner sensor) and Drum relay PWB (YC6) Drum relay PWB (YC1) and Main/Engine PWB (YC4) 2. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 3. Replace the developer unit K.

Drum relay PWB Replace the drum relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7201

- Description: Short-circuited inner thermistor (Developer) The sensor input sampling is less than the reference value. (After detection, controlled at 25 °C/77.0 °F)

- Remedy: Developer unit K 1. Confirm that the connector of developer unit K is firmly connected, and if necessary, push the unit all the way in. Developer unit K (toner sensor) and Drum relay PWB (YC6) Drum relay PWB (YC1) and Main/Engine PWB (YC15) 2. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 3. Replace the developer unit K.

Drum relay PWB Replace the drum relay PWB.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7221

- Description: Broken inner thermistor wire (LSU Magenta & Black) The sensor input sampling is greater than the reference value. (After detection, controlled at 25 °C/77.0 °F)

- Remedy: LSU (Magenta & Black) 1. Confirm that the wiring connector of LSU (Magenta & Black) is firmly connected, and if necessary, connect the connector all the way in. LSU (Magenta & Black) and Main/ Engine PWB (YC2016) 2. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 3. Replace the LSU (Magenta & Black).

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7222

- Description: Broken inner thermistor wire (LSU Cyan & Yellow) The sensor input sampling is greater than the reference value. (After detection, controlled at 25 °C/77.0 °F)

- Remedy: LSU (Cyan & Yellow) 1. Confirm that the wiring connector of LSU (Cyan & Yellow) is firmly connected, and if necessary, connect the connector all the way in. LSU (Cyan & Yellow) and Main/Engine PWB (YC2017) 2. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 3. Replace the LSU (Cyan & Yellow).

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB.

- Code: 7401

- Description: Developer unit K type mismatch error (Black) Improper adaptation of the main unit and developer unit is detected.

- Remedy: Developer unit K Check if the developer unit of different models is mounted, and replace it to the correct one.

- Code: 7402

- Description: Developer unit C type mismatch error (Cyan) Improper adaptation of the main unit and developer unit is detected.

- Remedy: Developer unit C Check if the developer unit of different models is mounted, and replace it to the correct one.

- Code: 7403

- Description: Developer unit M type mismatch error (Magenta) Improper adaptation of the main unit and developer unit is detected.

- Remedy: Developer unit M Check if the developer unit of different models is mounted, and replace it to the correct one.

- Code: 7404

- Description: Developer unit Y type mismatch error (Yellow) Improper adaptation of the main unit and developer unit is detected.

- Remedy: Developer unit Y Check if the developer unit of different models is mounted, and replace it to the correct one.

- Code: 7411

- Description: Drum unit K type mismatch error (Black) Improper adaptation of the main unit and drum unit is detected.

- Remedy: Drum unit K Check if the drum unit of different models is attached, and replace it to the correct one.

- Code: 7412

- Description: Drum unit C type mismatch error (Cyan) Improper adaptation of the main unit and drum unit is detected.

- Remedy: Drum unit C Check if the drum unit of different models is attached, and replace it to the correct one.

- Code: 7413

- Description: Drum unit M type mismatch error (Magenta) Improper adaptation of the main unit and drum unit is detected.

- Remedy: Drum unit M Check if the drum unit of different models is attached, and replace it to the correct one.

- Code: 7414

- Description: Drum unit Y type mismatch error (Yellow) Improper adaptation of the main unit and drum unit is detected.

- Remedy: Drum unit Y Check if the drum unit of different models is attached, and replace it to the correct one.

- Code: 7601

- Description: ID sensor L error (Left side) When the measured value of the ID sensor matches any of the following. If the light potential P-wave is lower than the dark potential P-wave (+0.5V). If light potential S-wave is lower than the dark potential S-wave. The dark potential P/S-wave is greater than 0.8V, or less than 0.15V.

- Remedy: ID sensor L (Left side) 1. Clean the ID sensor surface. 2. Check how the ID sensor is attached. 3. Check if the error is detected after performing the calibration. 4. Confirm that the wiring connector is firmly connected, and if necessary, connect the connector all the way in. ID sensor and Main/Engine PWB (YC13) 5. If the wiring is disconnected, short-circuited or has ground fault, replace the wire. 6. Replace the ID sensor.

Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. Replace the Main/Engine PWB.

- Code: 7602

- Description: ID sensor R error (Right side) When the measured value of the ID sensor matches any of the following. If the light potential P-wave is lower than the dark potential P-wave (+0.5V). If light potential S-wave is lower than the dark potential S-wave. The dark potential P/S-wave is greater than 0.8V, or less than 0.15V.