I have been working and repairing Sea-doo jet skis for the last 20 years. They are very reliable machines but occasionally things go wrong and like all smart vehicles that just display a fault code, it can be confusing. That’s why with the help of a few different Sea-doo workshop manuals I will be showing the full Sea-doo fault code list.

I have split the sections up into areas such as Cluster, iBR, Intelligent Suspension, VTS, and Engine Control Management to make codes simple to read.

As this is a very large document you can either scroll in alphabetic/numeric order or use the browser search function to find a specific Sea-doo fault code to fix it yourself.

Having access to the BRP BUDS or Candoo Pro scanning software is beneficial in tracking down faults but not necessary. I have used both and they work very well. I would recommend the BRP BUDS2 scanner when working on newer 4-Tec Sea-doos. It comes with an ALL-DEALER license to help fix your jet-ski and your friends.

Table of Contents

- 1 Mega Sea-doo fault code list

- 2 Sea doo fault codes for iBR

- 3 Sea-doo “iS” Faults (Stands for Intelligent Suspension)

- 4 Sea-doo ECM Fault codes

- 5 Sea-doo Electrical Fault Codes Continued

- 6 Sea-doo Throttle, CAN-BUS, and VTS Fault Codes List

- 7 Seadoo Code Reader – Candoo Pro and BRP BUDS.

- 7.1 BRP Sea-doo code reader specs

- 8 How to get a list of stored codes from your Sea-doo for 4TEC skis up to 2003

- 9 How to read Sea-doo fault codes on 2004 to 2021 models without a scanner.

- 10 Sea-doo warning lights messages and display meaning

- 11 Conclusion

| SEA-DOO FAULT CODES |

REPORTING MODULE |

DESCRIPTION | POSSIBLE CAUSE | REPAIR ACTION |

| B2210 | CLUSTER | Left keypad fault (Switch kept activated more than 60 seconds) |

Problem with left keypad. |

The switch may be defective, verify the functionality of the switch or the wires. Refer to the shop manual for switch diagnosis/testing procedure. |

| B2211 | CLUSTER | Suspension UP/DOWN switches shorted to ground fault |

Problem with left keypad. |

Look for pin B if shorted to ground or pin C. |

| B2212 | CLUSTER | Suspension UP/DOWN switches disconnected fault |

Problem with left keypad. |

Look for pin B if disconnected to pin 14 on the cluster. Look for pin C if disconnected to pin 15 on the cluster. |

| B2213 | CLUSTER | VTS UP/DOWN switches shorted to ground fault |

Problem with left keypad. |

Look for pin A if shorted to ground or if pin C is grounded. |

| B2214 | CLUSTER | VTS UP/DOWN switches disconnected fault |

Problem with left keypad. |

Look for pin A if disconnected to pin 13 on the cluster. Look for pin C if disconnected to pin 15 on the cluster. |

| B2220 | CLUSTER | Right keypad fault (Switch kept activated more than 60 seconds) |

Problem with the right keypad. |

The switch may be defective, verify the functionality of the switch or the wires. Refer to the shop manual for switch diagnosis/testing procedure. |

| B2221 | CLUSTER | MODE/SET switches shorted to ground fault |

Problem with the right keypad. |

Look for pin B if shorted to ground or pin C. |

| B2222 | CLUSTER | MODE/SET switches disconnected fault |

Problem with the right keypad. |

Look for pin B if disconnected to pin 17 on the cluster. Look for pin C if disconnected to pin 18 on the cluster. |

| B2223 | CLUSTER | UP/DOWN switches shorted to ground fault |

Problem with the right keypad. |

Look for pin A if shorted to ground or pin C. |

| B2224 | CLUSTER | UP/DOWN switches disconnected fault |

Problem with the right keypad. |

Look for pin A if disconnected to pin 16 on the cluster. Look for pin C if disconnected to pin 18 on the cluster. |

Sea doo fault codes for iBR

The Intelligent brake and reverse (iBR) helps the jetski stop sooner, improves safety, and gives you the ability to engage forward, neutral, and reverse. This is important for stable, easy maneuvers at low speeds. But occasionally things go wrong when the iBR gets jammed with sticks or debris.

| SEA-DOO FAULT CODE LIST | REPORTING MODULE | DESCRIPTION | POSSIBLE CAUSE | REPAIR ACTION |

| C0042 | iBR | Brake Lever Sensor (BRLS) signals A open/shorted to ground |

Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. |

Check for 0.5 to 3 V on pin F. and 0.25 to 1.5V on pin C. |

| C0043 | iBR | Brake Lever Sensor (BRLS) signals B open/shorted to ground |

Damaged sensor, damaged circuit wires, damaged connector or damaged iBR pins. Fault detected when the engine is running or stopped. |

Check for 0.5 to 3 V on pin F and 0.25 to 1.5 on pin C. |

| C0073 | iBR | Torque request failure | ECM software failure. CPS wires shorted. | Perform ECM software updates if available or replace ECM. Verify CPS connection. |

| C2100 | iBR | Sensors calibration is corrupted | Incompatible firmware or memory failure. | Replace the iBR unit. Refer to the Service Manual for more details. |

| C2101 | iBR | Actuator movement warning | The reverse gate cannot move to the desired position within the expected time. | Clean and check for damage in the reverse gate and nozzle area. Refer to the Service Manual for more details. |

| C2100 There are a few with the same code. |

iBR | Actuator movement | The reverse gate cannot move to the desired position. | Clean and check for damage in the reverse gate and nozzle area. Refer to the Service Manual for more details. |

| C2110 | iBR | Reverse gate position sensor error | iBR malfunction. | Check for correct movement of iBR.Replace the iBR unit. Refer to the Service Manual for more details. |

| C2110 | iBR | Angle position sensor warning | iBR malfunction. | Replace the iBR unit. Refer to the Service Manual for more details. |

| C2110 | iBR | iBR overheat | iBR cooling system failure. iBR unit failure. |

Check the iBR cooling circuit. Replace the iBR unit. Refer to the Service Manual for more details. |

| C2110 | iBR | Monitoring CPU message timeout or validity | iBR malfunction. | Perform an iBR software update if available. Replace the iBR unit. Refer to the Service Manual for more details. |

| C2110 | iBR | Monitoring CPU limp force | iBR malfunction. | Perform an iBR software update if available. Replace the iBR unit. Refer to the Service Manual for more details. |

| C2111 | iBR | ECM erratic RPM signal | RPM signal received from engine ECM not plausible | Check CPS sensor connection |

| C2120 | iBR | Application calibration is corrupted | Incompatible firmware or memory failure. | Perform an iBR software update if available. Replace the iBR unit. Refer to the Service Manual for more details. |

| C2121 | iBR | Application parameters corrupted (backup #1 or #2) | Battery power loss or memory failure. | Perform an electrical system shut download to clear the fault. Verify starting and charging system circuits. Refer to the Service Manual for more details. |

| 02122 | iBR | The last session interrupted |

Unexpected battery power lost. | Perform an electrical system shut down and clear fault. Verify starting and charging system circuits. Refer to the Service Manual for more details. |

| C2130 | iBR | Motor current software breaker | Motor current too high. | Clean and check for damage in the reverse gate and nozzle area. Refer to the Service Manual for more details. |

| C2130 | iBR | Internal motor drive failure | Motor voltage feedback not fitting with the command. | Check that the power cable to the motor is connected |

| C2131 | iBR | iBR DC motor shorted to ground or 12 V | iBR motor failure. iBR motor wires damaged or moisture detected |

Check iBR circuits A and B. Refer to the Service Manual for more details. |

| C2132 | iBR | Motor Open | No current while activated. | Check the power cables are connected. |

| C2142 | iBR | Brake Lever Sensor (BRLS) signals A shorted to battery | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. |

Check for 0.5 to 3 V on pin F and 0.25 to 1.5 on pin C. |

| C2143 | iBR | Brake Lever Sensor (BRLS) signals B shorted to battery | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. |

Check for 0.5 to 3 Von pin F and 0.25 to 1.5 on pin C. |

| C2144 | iBR | Brake Lever Sensor (BRLS) power shorted to battery | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. |

Check for 4.5 to 5 volts on sensor connector pin A & D. Refer to the Service Manual for more details. |

| C2145 | iBR | Brake Lever Sensor (BRLS) power shorted to ground | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. |

Check for 4.5 to 5 volts on sensor connector pin A & D. Refer to the Service Manual for more details. |

| C2146 | iBR | Brake Lever Sensor (BRLS) signals A/B reading difference | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. |

Check for 0.5 to 3 V on pin F and 0.25 to 1.5 on pin C. |

| C2150 | iBR | System current software breaker | iBR input current too high. | Clean and check for damage in the reverse gate and nozzle area. Refer to the Service Manual for more details. |

| C2151 | iBR | System disabled and need activation | The system is locked. Need activation. | Use B.U.D.S. iBR unlock function. Refer to the Service Manual for more details. |

| C2155 | iBR | Water temperature sensor overheat | iBR cooling system failure. iBR unit failure. |

Check the iBR cooling circuit. Sea-Doo coolant flush procedure. Replace the iBR unit. Refer to the Service Manual for more details. |

| C2161 | iBR | Low voltage detected | Battery failure, rectifier failure, damaged circuit wires, battery terminal connection, damaged AC generator or damaged connectors. |

Check fuses #6 (refer to WIRING DIAGRAM). Check ground continuity to the engine block. Refer to the Service Manual for more details. |

Sea-doo “iS” Faults (Stands for Intelligent Suspension)

Sea-Doo discontinued its Intelligent Suspension system in 2017 possibly due to costs, weight and for me, it just didn’t work very well. But there are a number of Jet-skis out there with this feature so below are the fault codes that can occur with Intelligent Suspension.

| SEA-DOO FAULT CODES | REPORTING MODULE |

DESCRIPTION | POSSIBLE CAUSE | REPAIR ACTION |

| C2200 | iS | Sensors calibration is corrupted | Incompatible firmware or memory failure (Internal memory failure, return to supplier). | Defective iS module, replace the module and return to supplier. |

| C2210 | iS | Bridge/CPU temperature sensor overheat |

Hardware failure or external heat source. | Check for overutilization/heat. |

| C2220 | iS | Application calibration is corrupted | Incompatible firmware or memory failure (B.U.D.S. should repair that). | Program calibration with B.U.D.S. software. |

| C2221 | iS | Application parameters corrupted (backup #1 or #2) | Battery power lost or memory failure (Reset after power-down-up, clear fault. If happens often, verify supply voltage). |

Check power wiring and fuse. |

| C2222 | iS | Last session interrupted |

Unexpected battery power lost. | Check power wiring and fuse. |

| C2230 | iS | Internal motor drive failure | Motor voltage feedback not fitting with the command. | Defective iS module, replace the module and return to supplier. |

| C2231 | iS | Motor shorted to ground/battery | Motor shorted to ground/battery | Check suspension actuator pump wiring. |

| C2232 | iS | Motor open | No current while activated. | Check suspension actuator pump and/or wiring. |

| C2233 | iS | Motor current software breaker | Motor current too high. | Check suspension actuator pump. |

| C2240 | iS | Seat position sensor error Open, Shorted to Ground | Sensor not connected | Check system circuit at iS module, (refer to WIRING DIAGRAM) |

| C2250 | iS | System current software breaker | Battery input current too high. | Check suspension actuator pump. |

| C2251 | iS | System disabled and need activation | The system is locked for safety. Need activation. | Activate iS using BRP B.U.D.S. fault scanner activation function. |

| C2252 | iS | TOPS active Tip-over protection |

Warning only! TOPS detected by the system, the suspension is disabled while the TOPS is “ON’. | Refer to the Service Manual for more details. |

| C2260 | iS | System under voltage | The system has an under-voltage warning. | Check battery and charging system. Replace Seadoo battery. |

Sea-doo ECM Fault codes

The Engine Control Module (ECM), also called the Engine Control Unit (ECU), ensures that your Sea-doo jetski operates at optimal performance. The ECM is looking at hundreds of parameters every second and will throw up a fault code if something is wrong to protect the engine.

| SEA-DOO FAULT CODE LIST |

REPORTING MODULE |

DESCRIPTION | POSSIBLE CAUSE | REPAIR ACTION |

| P0008 | ECM | Engine phase-detection fault | ||

| P0030 | ECM | Heater Power Stage fault for lambda sensor upstreams of catalyst |

||

| P0031 | ECM | Heater Power Stage fault for lambda sensor upstreams of catalyst short circuit to GNI) |

It can have several problems, but wiring being damaged by excessive heat from the exhaust is most common. Make certain the wiring is good and has proper voltage and ground to the sensor before replacing the sensor. Check if the ground wire on the HO2 sensor circuit is corroded |

|

| P0032 | ECM | Heater Power Stage fault for lambda sensor upstreams of catalyst short circuit to V+ |

It can have several problems, but wiring being damaged by excessive heat from the exhaust is most common. Make certain the wiring is in good condition and has proper voltage and ground to the sensor before replacing the sensor. Check if the ground wire on the HO2 sensor circuit is corroded |

|

| P0036 | ECM | Heater Power Stage fault for lambda sensor downstream of the catalyst |

This can mean that the specified sensor is not sending the right data to the PCM (powertrain control module). | |

| P0037 | ECM | Heater Power Stage fault for lambda sensor downstream of catalyst – short circuit to GND |

||

| P0038 | ECM | Heater Power Stage fault for lambda sensor downstream of catalyst – short circuit to V+ |

||

| P0106 | ECM | Intake pressure sensor out of range | Sensing port dirty or blocked. Sensor failure or unexpected reading at idle. The sensor has fallen out of housing or leaking inlet. |

Check system circuits A-64, A-G4, A-H2. Make sure that the sensor housing is correctly inserted into the manifold. Check sensor connector for: a)5 volts on pin 1. b)0 volt on pin 2. c)0 volt on pin 3. Refer to the Service Manual for more details |

| P0107 | ECM | Manifold absolute pressure sensor shorted to ground or not connected. |

Sensing port dirty or blocked. Sensor failure or unexpected reading at idle. The sensor has fallen out of housing or leaking inlet. Connector disconnected |

Check system circuits A-B4, A-G4, A-H2. Make sure that the sensor housing is correctly inserted into the manifold. Check sensor connector for: a)5 volts on pin 1. b)0 volt on pin 2. c)0 volt on pin 3. Refer to the Service Manual for more details. |

| P0108 | ECM | Manifold absolute pressure sensor open circuit or shorted to battery | Sensing port dirty or blocked. A sensor failure or unexpected reading at idle. The sensor has fallen out of housing or leaking inlet. |

Check system circuits A-B4, A-G4, A-H2. Make sure that the sensor housing is correctly inserted into the manifold. Check sensor connector for: a)5 volts on pin 1. b)0 volt on pin 2. c)0 volt on pin 3. Refer to the Service Manual for more details. |

| P0112 | ECM | Intake manifold temperature sensor shorted to ground | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins. | Check the sensor for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F). Check for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F) between ECM connector pins A-H3 and A-J3. Refer to the Service Manual for more details. |

| P0113 | ECM | Intake manifold temperature sensor open circuit or shorted to battery | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins. | heck the sensor for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F). Check for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F) between ECM connector pins A-H3 and A-J3. Refer to the Service Manual for more details. |

| P0116 | ECM | Engine coolant temperature signal not plausible | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins. | Check for debris Dr blockage in the cooling system. Check the sensor for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F). Check for approximately 2280 to 2736 Ohms at 19 to 21°C (66 to 70°F) between ECM connector pins A-Al and A-J2. Refer to the Service Manual for more details. |

| P0117 | ECM | Engine coolant temperature sensor fault – Short circuit to GND | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins. | Check for debris or blockage in the cooling system. Check the sensor for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F). Check for approximately 2280 to 2736 Ohms at 19 to 21°C (66 to 70°F) between ECM connector pins A-Al and A-J2. Refer to the Service Manual for more details. |

| P0118 | ECM | Engine coolant temperature sensor fault – Short circuit to V+ or connector disconnected. | Engine overheated or damaged sensor. Connector disconnected. | Check for debris or blockage in the cooling system. Check the sensor for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F). Check for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F) between ECM connector pins A-A1 and A-J2. Refer to the Service Manual for more details. |

| P0122 | ECM | TAS (Throttle Accelerator sensor) 1 fault (short circuit to GND) | Damaged sensor, damaged circuit wires, damaged connector or damaged ECM pins, | Check system circuits B-E1, B-K1, B-K3. Check for 0 volts on sensor connector pin E. Check for 5 volts on sensor connector pin D. Check for 0.5 to 3 volts on sensor connector pin F. Refer to the Service Manual for more details. |

| P0123 | ECM | TAS (Throttle Accelerator sensor) 1 fault (short circuit to the battery) | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins. | Check system circuits B-E1, B-K1, B-K3. Check for 0 volts on sensor connector pin E. Check for 5 volts on sensor connector pin D. Check for 0.5 to 3 volts on sensor connector pin F. Refer to the Service Manual for more details. |

| P0127 | ECM | Intercooler system fault | High air intake temperature detected. Fault detected when the engine is running and stopped. Blocked intercooler water circuit. | Clean intercooler water circuit system. Refer to the Service Manual for more details. |

| P0130 | ECM | Lambda Sensor fault upstreams of catalyst signal not plausible | ||

| P0131 | ECM | Lambda Sensor fault upstreams of catalyst short circuit to GND | Replace oxygen sensor find ground fault | |

| P0132 | ECM | Lambda Sensor fault upstreams of catalyst short circuit to V+ | Replace oxygen sensor | |

| P0133 | ECM | Oxygen sensor upstreams of catalyst react too slow —› contaminated | Clean replace the oxygen sensor | |

| P0134 | ECM | Oxygen sensor upstreams of catalyst react too slow —> defective | Clean replace the oxygen sensor | |

| P0135 | ECM | Lambda Sensor heating fault upstreams of catalyst | It can have several problems, but wiring being damaged by excessive heat from the exhaust is most common. Make certain the wiring is good and has proper voltage and ground to the sensor before replacing the sensor. Check if the ground wire on the HO2 sensor circuit is corroded |

|

| P0136 | ECM | Lambda Sensor fault downstream of catalyst – signal not plausible | It can have several problems, but wiring being damaged by excessive heat from the exhaust is most common. Make certain the wiring is good and has proper voltage and ground to the sensor before replacing the sensor. Check if the ground wire on the O2 sensor circuit is corroded |

|

| P0137 | ECM | Lambda Sensor fault downstream of catalyst – short circuit to GROUND | It can have several problems, but wiring being damaged by excessive heat from the exhaust is most common. Make certain the wiring is good and has proper voltage and ground to the sensor before replacing the sensor. Check if the ground wire on the O2 sensor circuit is corroded |

|

| P0138 | ECM | Lambda Sensor fault downstream of catalyst – short circuit to V+ | It can have several problems, but wiring being damaged by excessive heat from the exhaust is most common. Make certain the wiring is good and has proper voltage and ground to the sensor before replacing the sensor. Check if the ground wire on the O2 sensor circuit is corroded |

|

| P0141 | ECM | Lambda Sensor heating fault downstream of the catalyst | It can have several problems, but wiring being damaged by excessive heat from the exhaust is most common. Make certain the wiring is good and has proper voltage and ground to the sensor before replacing the sensor. Check if the ground wire on the O2 sensor circuit is corroded |

|

| P0171 | ECM | Multiplicative mixture adaptation exceeds the upper limit—> mixture too lean | ||

| P0172 | ECM | Multiplicative mixture adaptation below lower limit—> mixture too rich | ||

| P0201 | ECM | Injection Power Stage fault – open line/Cylinder 1 | Damaged injector, damaged circuit wires, damaged connector, or damaged ECM Output pins. | Check for 11.4 to 12.6 ohms between engine connector pin 2 and ECM connector pin A-B3. Check for 12 volts on pin 2 of injector connector. Check fuse #13 (refer to WIRING DIAGRAM). Check for damaged circuit wires. Refer to the Service Manual for more details. |

| P0202 | ECM | Injection Power Stage fault – Open line/Cylinder 2 | Damaged injector, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 11.4 to 12.6 ohms between engine connector pin 2 and ECM connector pin A-K1. Check for 12 volts on pin 2 of the injector connector. Check fuse #14 (refer to WIRING DIAGRAM). Check for damaged circuit wires Refer to the Service Manual for more details. |

| P0203 | ECM | Injection Power Stage fault – open line/Cylinder 3 | Damaged injector, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 11.4 to 12.6 ohms between engine connector pin 3 and ECM connector pin A-J1, Check for 12 volts on pin 2 of the injector connector. Check fuse #15 (refer to WIRING DIAGRAM). . Check for damaged circuit wires. Refer to the Service Manual for more details. |

| P0217 | ECM | High engine coolant temperature detected | High engine coolant temperature detected caused by a blockage in coolant ride plate, cooling system, or low coolant.

This Sea-doo fault code comes up often when seaweed is blocking the intake grate. |

Check for debris or blockage in the cooling system. Check the sensor for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F). Check for approximately 2280 to 2736 ohms at 19 to 21°C (66 to 70°F) between ECM connector pins A-Al and A-J2. Refer to the Service Manual for more details. |

| P0222 | ECM | TAS (Throttle Accelerator sensor) 2 fault (short circuit to GND) | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins. | Check system circuits B-A3, B-B3, B-J3. Check for 0 volts on sensor connector pin B. Check for 5 volts on sensor connector pin A. Check for 0.25 to 1.5 volts on sensor connector pin C, Refer to the Service Manual for more details. |

| P0223 | ECM | TAS (Throttle Accelerator sensor) 2 fault (short circuit to the battery) | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins. | Check system circuits B-A3, B-B3, 8-J3. Check for 0 volt Dn sensor connector pin B. Check for 5 volts on sensor connector pin A. Check for 0.25 to 1.5 volts on sensor connector pin C. Refer to the Service Manual for more details. |

| P0231 | ECM | Fuel pump open circuit or short to ground | Damaged pump, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for approximately 1 ohm between pins A and B of the fuel pump connector. Check fuse #18 (refer to WIRING DIAGRAM). Check for damaged circuit wires. Check for damaged connector, damaged ECM Output pins or ECM failure. Refer to the Service Manual for more details. |

| P0232 | ECM | Fuel pump short circuit to battery | Damaged pump, damaged circuit wires, damaged connector, or damaged ECM Output pins. | Check for approximately 1 ohm between pins A and B of the fuel pump connector. Check fuse #16 (refer to WIRING DIAGRAM). Check for damaged circuit wires. Check for damaged connector, damaged ECM output pins or ECM failure. Refer to the Service Manual for more details. |

| P0261 | ECM | Injector 1 open circuit or shorted to ground |

Damaged injector, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 11.4 to 12.6 ohms between engine connector pin 1 and ECM connector pin A-B3. Check for 12 volts on pin 2 of the injector connectors. Check fuse #13 (refer to WIRING DIAGRAM), Check for damaged circuit wires. Refer to the Service Manual for more details. |

| P0262 | ECM | Injector 1 shorted to battery | Damaged injector, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 11.4 to 12.6 ohms between engine connector pin 1 and ECM connector pin A-83. Check for 12 volts on pin 2 of the injector connector. Check fuse #13 (refer to WIRING DIAGRAM). Check for damaged circuit wires. Refer to the Service Manual for more details. |

| P0264 | ECM | Injector 2 open circuit or shorted to ground | Damaged injector, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 11.4 to 12.6 ohms between engine connector pin 2 and ECM connector pin A-K1. Check for 12 volts on pin 2 of the injector connectors. Check fuse #14 (refer to WIRING DIAGRAM). Check for damaged circuit wires. Refer to the Service Manual for more details. |

| P0265 | ECM | Injector 2 shorted to battery | Damaged injector, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 11.4 to 12.6 ohms between engine connector pin 2 and ECM connector pin A-KI. Check for 12 volts on pin 2 of the injector connector. Check fuse #14 (refer to WIRING DIAGRAM). Check for damaged circuit wires. Refer to the Service Manual for more details. |

| P0267 | ECM | Injector 3 open circuit or shorted to ground | Damaged injector, damaged circuit wires, damaged connector, or damaged ECM Output pins. | Check for 11.4 to 12.6 ohms between engine connector pin 3 and ECM connector pin A-.11. Check for 12 volts on pin 2 of the injector connector. Check fuse #15 (refer to WIRING DIAGRAM). Check for damaged circuit wires. Refer to the Service Manual for more details. |

| P0268 | ECM | Injector 3 shorted to battery | Damaged injector, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 11.4 to 12.6 ohms between engine connector pin 3 and ECM connector pin A-J1. Check for 12 volts on pin 2 of the injector connector. Check fuse #15 (refer to WIRING DIAGRAM). Check for damaged circuit wires. Refer to the Service Manual for more details. |

| P0300 | ECM | Multiple misfires detected | Check coil and spark plugs. | |

| P0301 | ECM | Misfire cylinder 2 (physical cylinder 1) | Check coil and spark plugs. | Replace Sea-doo spark plugs and coil |

| P0302 | ECM | Misfire cylinder 2 (physical cylinder 1) | Check coil and spark plugs. Water ingress into the electrical system. | Replace spark plugs and coil |

| P0303 | ECM | Misfire cylinder 1 (physical cylinder 3) | Check coil and spark plugs. Water ingress. | Replace spark plugs and coil |

| P0325 | ECM | Knock sensor 1 fault | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM output pins. Open circuit. | Bring the engine to 5000 RPM. If fault code appears then check for approximately 5 M ohms between system circuits A-C3 and A-G2. Refer to the Service Manual for more details. |

| P0330 | ECM | Knock sensor 2 fault | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM output pins. Open circuit. | Bring the engine to 5000 RPM. If fault code appears then check for approximately 5 Mohms between system circuits A-C3 and A-G2. Refer to the Service Manual for more details. |

Sea-doo Electrical Fault Codes Continued

| SEA-DOO FAULT CODES | REPORTING MODULE |

DESCRIPTION | POSSIBLE CAUSE |

REPAIR ACTION |

| P0335 | ECM | Crankshaft signal error | Damaged sensor, damaged circuit wires, damaged connector, damaged ECM pins, or damaged tooth wheel. Connector disconnected. | For the CPS, check for 700 to 900 ohms between terminals A-H1 and A-K2 of the ECM connector. Refer to the Service Manual for more details. |

| P0340 | ECM | Camshaft 1 signal error | Damaged sensor, damaged circuit wires, damaged connector, damaged ECM pins, or damaged tooth wheel. Connector disconnected. | For the CAPS, check for 12 volts on sensor connector pin 3. Check continuity for circuits A-D4, A-E2, and terminal 4 on engine connector. Check fuse #12 (refer to WIRING DIAGRAM). Engine must run to erase the corrected fault. Refer to the Service Manual for more details. |

| P0351 | ECM | Ignition coil 1 open circuit or shorted to ground or to battery |

Damaged coil, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 0.85 to 1.15 Ohms between engine connector pin 1 and ECM connector pin A-M4. Check for 12 volts on pin 2 of the coil connector. Check fuse #13 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0352 | ECM | Ignition coil 2 open circuit or shorted to ground or to battery |

Damaged coil, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 0.85 to 1.15 ohms between engine connector pin 1 and ECM connector pin A-M2. Check for 12 volts on pin 2 of the coil connector. Check fuse #14 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0353 | ECM | Ignition coil 3 open circuit or shorted to ground or to battery |

Damaged coil, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 0.85 to 1.15 ohms between engine connector pin 3 and ECM connector pin A-M1. Check for 12 volts on pin 2 of the coil connector. Check fuse #15 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0354 | ECM | Ignition Power Stage fault – short circuit to GND/Cylinder 1 | Damaged coil, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 0.85 to 1.15 ohms between engine connector pin 1 and ECM connector pin A-M4. Check for 12 volts on pin 2 of the coil connector. Check fuse #13 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0355 | ECM | Ignition Power Stage fault – short circuit to GND/Cylinder 2 | Damaged coil, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 0.85 to 1.15 ohms between engine connector pin 1 and ECM connector pin A-M2. Check for 12 volts on pin 2 of the coil connector. Check fuse #14 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0356 | ECM | Ignition Power Stage fault – short circuit to GND/Cylinder 3 | Damaged coil, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 0.85 to 1,15 ohms between engine connector pin 3 and ECM connector pin A-M1. Check for 12 volts on pin 2 of the coil connector. Check fuse #15 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0357 | ECM | Ignition Power Stage fault – short circuit to V+/Cylinder 1 | Damaged coil, damaged circuit wires, damaged connector Dr damaged ECM output pins. | Check for 0.85 to 1,15 ohms between engine connector pin 1 and ECM connector pin A-M4. Check for 12 volts on pin 2 of the coil connector. Check fuse #13 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0358 | ECM | Ignition Power Stage fault – short circuit to V+/Cylinder 2 | Damaged coil, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for 0.85 to 1.15 ohms between engine connector pin 1 and ECM connector pin A-M2. Check for 12 volts Dn pin 2 of coil connector. Check fuse #14 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0359 | ECM | Ignition Power Stage fault – short circuit to V+/Cylinder 3 | Damaged coil, damaged circuit wires, damaged connector Dr damaged ECM output pins. | Check for 0.85 to 1.15 ohms between engine connector pin 3 and ECM connector pin A-M1. Check for 12 volts on pin 2 of the coil connector. Check fuse #15 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0360 | ECM | Ignition Power stage max error & false detection of low battery voltage/Cylinder 1 | Signal not plausible, verify battery voltage too low during ignition. | Check for 0.85 to 1.15 Ohms between engine connector pin 1 and ECM connector pin A-M4. Check for 12 volts on pin 2 of the coil connector. Check fuse #13 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0361 | ECM | Ignition Power stage max error & false detection of low battery voltage/Cylinder 2 | Signal not plausible, verify battery voltage too low during ignition. | Check for 0.85 to 1.15 ohms between engine connector pin 1 and ECM connector pin A-M2. Check for 12 volts on pin 2 of the coil connector. Check fuse #14 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0362 | ECM | Ignition Power stage max error & false detection of low battery voltage/Cylinder 3 | Signal not plausible, verify battery voltage too low during ignition. | Check for 0.86 to 1.15 ohms between engine connector pin 3 and ECM connector pin A-M1. Check for 12 volts on pin 2 of the coil connector. Check fuse #15 (refer to WIRING DIAGRAM). Refer to the Service Manual for more details. |

| P0365 | ECM | Camshaft 2 signal error | Replacement of the sensor, along with a repair of the oil leak responsible for contaminating the sensor. Wiring damage and corroded connectors and earth are also often common problems. |

|

| P0500 | ECM | Vehicle speed signal fault | Cluster fault detected by ECM C.A.N. circuit failure, Instrument cluster, or ECM failure | Check C.A.N. circuits wires. Replace instrument Cluster. Verify Outside of the building if the GPS LED becomes active after 1 minute and stays steady Refer to the Service Manual for more details. |

| P0501 | ECM | Vehicle speed not plausible | Cluster or iBR fault detected by ECM. C.A.N. circuit failure, Instrument cluster, iBR, or ECM failure. | Check C.A.N. circuits wires. Replace instrument Cluster. Verify outside of the building if the GPS LED becomes active after 1 minute and stays steady Refer to the Service Manual for more details. |

| P0504 | ECM | Vehicle speed not plausible | iBR fault detected by ECM. C.A.N. circuit failure, ECM software failure. |

Check C.A.N. circuits wires. Replace iBR. Refer to the Service Manual for more details. |

| P0512 | ECM | The starter power stage detects high current | Damaged solenoid, damaged circuit wires, damaged connector, or damaged ECM. | Verify fuse #16 (5AIVIP). Check for 12 volts on pin 2 of the starter relay. Check earth. Refer to the Service Manual for more details. |

| P0513 | ECM | Invalid D.E.S.S. Key detected | Key not programmed in ECU. | Replace or program a good key. |

| P0520 | ECM | Oil pressure switch functional problem | Engine leak, oil pump failure, damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins | Check resistance at 0 RPM and above 3500 RPM, Switch is normally closed, ECM connector pin A-E3 When blow-by pressure exceeds 40 kPa (6 PSI), the resistance is infinitely high. Refer to the Service Manual for more details. |

| P0523 | ECM | Oil pressure sensor fault | Engine leak, oil pump failure, damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins. Fault detected when the engine is running or stopped. | Check resistance at 0 RPM and above 3500 RPM. When blow-by pressure exceeds 40 kPa (6 PSI), the resistance is infinitely high. Refer to the Service Manual for more details. |

| P0524 | ECM | Low oil pressure condition | Low Oil level, engine leak, oil pump fault. | Check the oil level in the engine. Blocked oil filter. How to do an easy Oil Change on a Sea-doo PWC. Check impedance of the sensor. Refer to the Service Manual for more details. |

| P0544 | ECM | Exhaust gas temperature sensor functional problem | Damaged sensor, damaged circuit wires, damaged connecter, or damaged ECM output pins. | Check for approximately 2280 to 2736 ohms at a temperature of 19 to 21°C (66 to 70°F) between system circuits A-H4 and A-J4. Refer to the Shop Manual for more details. |

| P0545 | ECM | Exhaust gas temperature sensor shorted to ground |

Damaged sensor, damaged circuit wires, damaged connecter, or damaged ECM output pins. | Check for approximately 2280 to 2736 ohms at a temperature of 19 to 21°C (66 to 70°F) between system circuits A-H4 and A-J4. Refer to the Service Manual for more details |

| P0546 | ECM | Exhaust gas temperature sensor open circuit or shorted to battery | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for approximately 2280 to 2736 ohms at a temperature of 19 to 21°C (86 to 70°F) between system circuits A-H4 and A-J4. Refer to the Service Manual for more details. |

| P0560 | ECM | Battery voltage is not plausible | Battery failure, rectifier failure, damaged circuit wires, battery terminal connection, damaged AC generator or damaged connectors. | Check fuses #6 (refer to WIRING DIAGRAM). Check ground continuity to the engine block. Refer to the Service Manual for more details |

| P0562 | ECM | Battery voltage too low | Battery failure, rectifier failure, damaged circuit wires, battery terminal connection, damaged AC generator, or damaged connectors. |

Check fuses #6 (refer to WIRING DIAGRAM). Check ground continuity to the engine block. Charge the battery with a smart charger. Refer to the Service Manual for more details |

| P0563 | ECM | Battery voltage too high | Battery failure, rectifier failure, or battery terminal connection. | Check for regulator-rectifier failure. Make sure if jump-starting the battery that you are connected in parallel and not series. Refer to the Service Manual for more details. |

| P0564 | CLUSTER | Cruise switch fault | The cruise switch is shorted or activated for more than 60 seconds. | Verify the cruise switch if it is normally open and close when activated. Sticky switch replace. |

| P0606 | ECM | ECM ADC fault | Damaged ECM. | Replace damaged ECM. |

| P060D | ECM | TAS (Throttle Accelerator sensor) synchronization error | Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM pins. | Check system circuits B-El, B-K1, B-K3, B-A3, B-B3, B-J3. Check for 0 volts on sensor connector pin B and E. Check for 5 volts on sensor connector pin A and D. Check for 0.5 to 3 volts on sensor connector pin F and 0.25 to 1.5 volts on C Refer to the Service Manual for more details. |

| P060E | ECM | Throttle Actuator – Controller Fault-digital position control exceeds the limit. | ||

| P0610 | ECM | Variant coding fault | ||

| P0629 | CLUSTER | Fuel sensor disconnected fault |

Damaged sensor, damaged circuit wires, damaged connector Dr damaged ECM output pins. | Check for 2.6 ohms (full tank) to 93.6 ohms (empty tank) between pin C and pin D at the fuel pump connector. Check the system circuit at the gauge Pin 19 and 20. (refer to WIRING DIAGRAM). |

| P062C | ECM | Cluster CAN error – Loss of vehicle speed information from the cluster | Cluster fault detected by ECM. C.A.N. circuit failure, Instrument cluster, or ECM failure. | Check C.A.N. circuits wires. Replace instrument Cluster. Verify outside of the building if the GPS LED becomes active after 1 minute and stays steady Refer to the Service Manual for more details. |

| P062F | ECM | ECM EEPROM fault – exchange ECM | Damaged ECM. | Replace damaged ECM. |

| P06B6 | ECM | ECM Fast ADC fault (knock detection line) | ||

| P1030 P1036 |

ECM | Heater Power Stage | ||

| P1106 | ECM | Altitude correction | ||

| P1120 | ECM | Throttle positions calculated from TPS 1 and TPS 2 not corresponding | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S code scanner. Replace throttle actuator, replace ECM. |

| P1130 P1136 |

ECM | Lambda Sensor fault | Lambda Sensor fault upstream of the catalyst, replace the sensor. | |

| P1171 | ECM | Additive mixture too lean | An open signal on the coolant temperature sensor (CTS) can trigger this fault. | |

| P1172 | ECM | Additive mixture too rich | An open signal on the coolant temperature sensor (CTS) can trigger this fault. | |

| P1264 | ECM | Ignition Power stage overload | Damaged coil, replace. Damaged circuit wires, damaged connector, or damaged ECM output pins. |

|

| P1502 | ECM | T.O.P.S functional problem | Boat, Jet-ski, or sensor upside down, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check continuity for circuits A-C4, A-G1, A-F4. Refer to the Service Manual for more details. |

| P1503 | ECM | T.O.P.S switch short circuit to 12 V | Boat or sensor upside down, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check continuity circuits A-C4, A-G1, A-F4. Refer to the Service Manual for more details. |

| P1504 | ECM | T.O.P.S switch short circuit ground | Boat or sensor upside down, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check continuity circuits A-C4, A-G1, A-F4. Refer to the Service Manual for more details. |

| P1505 | ECM | T.O.P.S switch fault non-plausible state | Boat or sensor upside down, damaged circuit wires, damaged connector, or damaged ECM output pins. Open circuit. | Check continuity for circuits A-C4, A-G1, A-F4. Refer to the Service Manual for more details. |

| P1506 | ECM | T.O.P.S switch open circuit | Boat or sensor upside down, damaged circuit wires, damaged connector, or damaged ECM output pins. Open circuit. | Check continuity for circuits A-C4, A-G1, A-F4. Refer to the Service Manual for more details. |

| P1509 | ECM | Lake Water Temperature sensor fault |

Clean or replace the sensor |

Sea-doo Throttle, CAN-BUS, and VTS Fault Codes List

| SEA-DOO FAULT CODES | REPORTING MODULE |

DESCRIPTION | POSSIBLE CAUSE | REAPIR ACTION |

| P1550 | ECM | O.T.A.S sensor voltage not plausible | Sensor or a magnet out of place | Check for rust on the magnet or sensor. Clean. Replace magnet or sensor. See this post on P1550 OTAS fix for more information. |

| P1590 | ECM | VTS position sensor circuit out of range | ||

| P1591 | ECM | VTS position sensor circuit voltage low | ||

| P1592 | ECM | VTS position sensor circuit voltage high | ||

| P1593 | ECM | VTS malfunction | ||

| P1606 | ECM | ECM ADC fault – exchange ECM | Damaged ECM. | No service action is available for fault P1606. |

| P160E | ECM | Throttle Actuator – Controller Fault – digital position control below the limit | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with BRP B.U.D.S Diagnostic Scanner. Replace throttle actuator, replace ECM module. |

| P1610 | ECM | Throttle Actuator – Power Stage fault | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1611 | ECM | Throttle Actuator – Power Stage fault | Damaged throttle actuator, damaged circuit wires, damaged connector or damaged ECM, | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1612 | ECM | Throttle Actuator – Power Stage fault | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1613 | ECM | Throttle Actuator – Power Stage fault | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1614 | ECM | Throttle Actuator – Return-Spring check not passed/Spring does not close | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, cable, replace ECM. |

| P1615 | ECM | Throttle Actuator – Position monitoring fault | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1616 | ECM | Throttle Actuator – Default position check or learning fault | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1619 | ECM | Throttle Actuator – Adaptation of upper mechanical limit failed | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1619 | ECM | Throttle Actuator – Adaptation of upper mechanical limit failed | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1620 | ECM | Throttle Actuator – Adaptation of lower mechanical limit failed | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1621 | ECM | Throttle Actuator – Abortion of adaptation | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1622 | ECM | Throttle Actuator – Repeated abortion of adaptation | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1654 | ECM | The voltage of D.E.S.S, key switch out of range. DESS stands for ‘digital encoded security system’. |

Damaged D.E.S.S. key switch, damaged circuit wires, damaged connector, or damaged ECM output pins. | Remove the D.E.S.S. key and check system circuit B-B2. Refer to the Service Manual for more details. |

| P1657 | ECM | Electrical- fault of D.E.S.S. key communication line |

Damaged D.E.S.S. key switch, damaged circuit wires, damaged connector, or damaged ECM output pins. | Remove the D.E.S.S. key and check system circuit B-B2. Refer to the Service Manual for more details. |

| P1658 | ECM | Faulty D.E.S.S. key communication | Damaged D.E.S.S. key switch, damaged circuit wires, damaged connector, or damaged ECM output pins. | Remove the D.E.S.S. key and check system circuit B-B2. Refer to the Service Manual for more details. |

| P1661 | ECM | iBR malfunction | iBR fault detected by ECM. | Remove D.E.S.S. key Perform an electrical system shut down. Clear fault. |

| P1662 | ECM | iBR torque request is not plausible | iBR fault detected by ECM. | Perform iBR software update if available or replace iBR. |

| P1679 | ECM | Main Relay Sticking | Permanent 12 V is present on ECM Pin B-M4. | ECU pin B-M4 is permanently supplied thru a 15 amp fuse and it should be accessory 12 Vdc. |

| P1690 | ECM | VTS control up circuit open circuit or shorted to ground | ||

| P1691 | ECM | VTS control up circuit shorted to battery | ||

| P1692 | ECM | VTS control down circuit open circuit or shorted to ground | ||

| P1693 | ECM | VTS control down circuit shorted to battery |

||

| P1694 | ECM | VTS Power stage fault | ||

| P1695 | ECM | VTS Power stage fault | ||

| P1686 | ECM | ECU Fast ADC fault (knock detection line) | ||

| P1687 P1688 P16B7 P16B8 |

ECM | ECU Fast ADC fault (knock detection line) | ||

| P16C0 P16C1 |

ECM | The fault of ECM ADC | ||

| P16C2 | ECM | The fault of ECM monitoring module | ||

| P16C3 | ECM | Monitoring fault due to Accelerator Sensor check | ||

| P16C4 | ECM | Monitoring fault due to engine speed check | ||

| P16C5 | ECM | Safety fuel cut off active – Monitoring level 1 | ||

| P16C6 | ECM | Safety fuel cut off active – Monitoring level 2 | ||

| P1607 | ECM | Monitoring fault due to throttle valve plausibility check | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1608 | ECM | Monitoring fault due to exceeding permitted throttle valve position | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P1609 | ECM | Monitoring detected non-plausible D.E.S.S. key state | Damaged D.E.S.S. key switch, damaged circuit wires, damaged connector, or damaged. | Remove D.E.S.S. key and check system circuit B-B2. Refer to the Service Manual for more details. |

| P16CA | ECM | ECU detected faulty watchdog line ECU defect | Damaged ECM. | Replace Damaged ECM. |

| P160B | ECM | ECU switch off through watchdog line (hardware fault) ECU defect | Damaged ECM. | Replace Damaged ECM. |

| P2080 | ECM | Exhaust temperature not plausible | Damaged sensor, damaged circuit wires, damaged connector Dr damaged ECM output pins. | Check for approximately 2280 to 2736 ohms at a temperature of 19 to 21°C (66 to 70°F) between system circuits A-H4 and A-J4. Refer to the Service Manual for more details. |

| P2081 | ECM | Exhaust temperature sensor fault | Intermittent connection. Damaged sensor, damaged circuit wires, damaged connector, or damaged ECM output pins. | Check for approximately 2280 to 2736 ohms at a temperature of 19 to 21°C (66 to 70°F) between system circuits A-H4 and A-J4. Refer to the Service Manual for more details. |

| P212C | ECM | Electrical lower-range violation TPS 2 | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM |

| P212D | ECM | Electrical upper-range violation TPS 2 | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM |

| P2159 | ECM | TAS (Throttle Accelerator sensor) signal not plausible | ||

| P2245 | ECM | Lambda Sensor aging fault downstream of catalyst Sensor Voltage too low | Replace sensor | |

| P2246 | ECM | Lambda Sensor aging fault downstream of catalyst Sensor Voltage too high | Replace sennsor | |

| P2428 | ECM | High exhaust temperature detected |

Exhaust system overheating, damaged sensor, or damaged circuit wires. | Check the cooling system for blockage. Check if the exhaust injection valve is properly calibrated. Refer to the Service Manual for more details. |

| P2620 | ECM | TPS value not plausible | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P2621 | ECM | Electrical lower-range violation TPS 1 | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| P2622 | ECM | Electrical upper-range violation TPS 1 | Damaged throttle actuator, damaged circuit wires, damaged connector, or damaged ECM. | Check system circuit, perform closed throttle with B.U.D.S. Replace throttle actuator, replace ECM. |

| U0129 | ECM | CAN-BUS communication error between ECM and iBR module | iBR fault detected by ECM. C.A.N. circuit failure, iBR, or ECM failure. Disconnected connector. |

Check C.A.N. circuits wires. Replace iBR. Refer to the Service Manual for more details. |

| U0129 | iS | IBR CAN messages timeout or validity | Warning only: the iS module lost communication with the iBR. | If fault ACTIVE, verify CAN connection between iBR and iS. |

| U016A | ECM | Loss of vehicle speed | Instrument cluster fault detected by ECM. C.A.N. circuit failure, instrument Cluster, or ECM failure. | Check C.A.N. circuits wires, replace instrument Cluster. Refer to the Service Manual for more details. |

| U0300 | ECM | Exchange security – Wrong ECM | Incorrect ECM or cluster for the engine. | Install proper recommended ECM or cluster for the vehicle. |

| U0401 | iBR | ECM CAN messages timeout or validity | C.A.N. circuit failure, ECM software failure. | Check C.A.N. circuits wires. Replace ECM. Refer to the Service Manual for more details. |

| U0401 | iS | ECM CAN messages timeout or validity | Warning only: the iS module lost communication with the engine ECU. | If fault ACTIVE, verify CAN connection between ECM and iS. |

| U0457 | iBR | Cluster CAN messages timeout or validity | C.A.N. circuit failure, Cluster software failure. | Check C.A.N. circuits wires. Replace instrument Cluster. Refer to the Service Manual for more details. |

| U0457 | iS | Cluster CAN messages timeout Dr validity | Warning only: the iS module lost communication with the Cluster. | If fault ACTIVE, verify CAN connection between Cluster and iS. |

| U16A1 | ECM | Cluster CAN Timeout error-Missing CAN ID 514h | Cluster fault detected by ECM. C.A.N. circuit failure, Instrument cluster, or ECM failure. | Check C.A.N. circuits wires. Replace instrument Cluster. Refer to the Service Manual for more details. |

| U16A2 | ECM | Cluster CAN Timeout error-Missing CAN ID 230h | Cluster fault detected by ECM. C.A.N. circuit failure, Instrument cluster, or ECM failure | Check C.A.N. circuits wires. Replace instrument Cluster. Refer to the Service Manual for more details. |

| U16A3 | ECM | Cluster CAN Timeout error-Missing CAN ID 40Bh | Cluster fault detected by ECM. C.A.N. circuit failure, Instrument cluster, or ECM failure. | Check C.A.N. circuits wires. Replace instrument Cluster. Refer to the Service Manual for more details. |

| U16A4 | ECM | iBR CAN Timeout error-Missing CAN ID 010h | iBR fault detected by ECM. C.A.N. circuit failure, iBR, or ECM failure. Disconnected connector. |

Check C.A.N. circuits wires. Replace iBR. Refer to the Service Manual for more details. |

| U16A5 | ECM | iBR CAN Timeout error-Missing CAN ID 012h | iBR fault detected by ECM. C.A.N. circuit failure, iBR, or ECM failure. Disconnected connector. |

Check C.A.N. circuits wires. Replace instrument iBR. Refer to the Service Manual for more details. |

| U16A6 | ECM | Cluster checksum error – CAN ID230h | Cluster fault detected by ECM. C.A.N. circuit failure, Instrument cluster, or ECM failure. | Check C.A.N BUS circuits wires. Replace instrument Cluster. Refer to the Service Manual for more details. |

| U16A7 | ECM | Cluster checksum error – CAN ID408h | Cluster fault detected by ECM. C.A.N. circuit failure, Instrument cluster, or ECM failure | Check C.A.N. circuits wires. Replace instrument Cluster. Refer to the Service Manual for more details. |

| U16A8 | ECM | 1131-i checksum error – CAN ID010h | iBR fault detected by ECM. C.A.N. circuit failure, ECM software failure. |

Check C.A.N. circuits wires. Replace iBR. Refer to the Service Manual for more details. |

| U16A9 | ECM | 1131-i checksum error – CAN ID020h | iBR fault detected by ECM. C.A.N. circuit failure, ECM software failure. |

Check C.A.N. circuits wires. Replace iBR. Refer to the Service Manual for more details. |

| U16AA | ECM | Cluster CAN Timeout Error missing CAN 1D 410h |

||

| U16AB | ECM | Cluster checksum error – CAN ID410h |

Seadoo Code Reader – Candoo Pro and BRP BUDS.

There are two great Sea-doo code readers on the market.

- BRP BUDS / BUDS2 MPI-3 Diagnostic Scanner 4TEC/ETEC for Sea-doo, Ski-doo, Canam, Lynx

- Candoo Pro for all BRP Seadoo model Jetki and Ski-doos.

In the past, you could only get public access to the Candoo Pro code reader. Lately, BRP has made their dealer and technician Seadoo code reader available to the public. They are both slightly pricey but you will save on dealer workshop fees. I can work on my own Sea-doo now and after a few Sea-doo oil changes, my costs are only oil, filters, and spark plugs.

I have the Candoo Pro but my mate has the BRP BUDS2 and they are very similar in features. I even changed my spare learners DESS key and turned it into a full-speed key.

BRP Sea-doo code reader specs

- BRP MPI-3 Interface (main unit, is used for diagnosis of all BRP vehicles)

- Diagnostic Cable (for connection of MPI-3 Interface to 4-TEC/E-TEC vehicles

- BRP B.U.D.S. Diagnostic software with ALL-DEALER license (supports BRP vehicle till 2016)

- BRP B.U.D.S.2 Diagnostic software with DEALER TECHNICIAN license (supports BRP vehicle from 2016 and after)

How to get a list of stored codes from your Sea-doo for 4TEC skis up to 2003

With the engine, off, plug in your lanyard and hit SET 5 times. You will be able to cycle through these codes. You will see a list of codes on the display. If nothing comes up you need a dealer to read the codes.

How to read Sea-doo fault codes on 2004 to 2021 models without a scanner.

- Press the MODE button repetadly untill the Fault Code funtion is displayed on the console.

- Press the SET buttor and the UP/DOWN buttons to cycle through any stores or active fault codes to select them.

- Contrinnue to press the UP/Down buttons to scroll to the next fault code.

- If there is no faults active then the console will display NO ACTIVE FAULT CODES.

- To exit out of the Fault code section press MODE or SET once.

Sea-doo warning lights messages and display meaning

If you see the following pictures pop up on your Sea-doo GTI, GTR, GTS, RXT, GTX, or RXP display you will need to rectify the problem.

- High temperature

- Check Engine or Limp mode

- Low/High battery voltage

- iBR module error

- Low oil pressure

Conclusion

There are over 230 Sea-doo fault codes listed here and even though the solution is basic it will give you a good starting point to repair your Sea-doo jet-ski. Often the fix will be simple such as why your Jetski turns over but won’t start.

These alarm codes give you a very good indication of where to start. Most of the faults that I have come across are because of people not taking care of their Jes-ski. Remember to winterize your Sea-doo so it will be ready for next season.

Let me know in the comments below if I have missed any Sea doo fault codes and I will add them to the list.

I am a qualified Industrial Electrician for the past 20 years and I love to share my knowledge on home repair jobs.

I love fast toys like Motorcycles, Cars, Jetskis, and Boats so writing about them is easy.

To keeps costs down I do all my own mods, repairs, and servicing. These skills I want to share with everyone. DIY is a skill everyone can learn.

-

#1

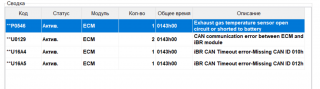

Полдня откатали нормально, не топили. Постоял, завел, поехал, вылез чек, IBR ушел в верхнее положение, мотор в аварийный режим. IBR не насиловал, ошибок не было.

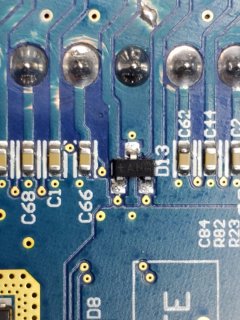

Разъемы сухие, проводку от ECM до IBR прозвонил, ок! Блок снял, вскрыл, чистый, сухой!

Разъем в блоке пропаял, проводку еще раз проверил, проблема осталась…

Три ошибки, все по CAN шине. Скрины и вскрытый блок во вложении.

На плате разъема, белыми точками, отмечены CAN дата, по дорожкам далее, 3х ногая смд tan33 (что это?), далее разводка в многослойку…

Новый блок только под заказ и жаба…

Есть мысли куда копать, ну или может кто ремонтировал уже?

-

109,5 KB

Просмотры: 191 -

222,8 KB

Просмотры: 191 -

168,5 KB

Просмотры: 170

-

#2

Привет, проверьте напряжение которое выходит на мотор IBR. по этношению к земле на 1-2 ношке должно быть по 6 вольт.

ЕСЛИ НЕТУ напряжения — выбиты ключи. ОНИ НАХОДИТСЯ под платой на 2- плате .

проверьте и напишите ответ. чтобы я мог вам дальше помоччь.

-

#3

Всем здравствуйте!Такая же проблема вылезла только я чуть подтопил гидрик Воду слили стал заводить загорелся ibr и чек.Снял полностью ibr когда вскрыл вытекло немного воды где плата стоит,просушил сильно- присильно)Сгорел предохранитель возле Акума на 30А поменял,ставлю на место сразу ibr пищит на панели а в плате что то щёлкает и ничего не работает (

-

#4

Проверь CAN шину от IBR до мозгов

-

#6

Хорошо сегодня попробую.Отпишусь

Если хотите разместить ссылку на Гидрик.ру — Клуб любителей гидроциклов и другой техники для активного отдыха, используйте этот HTML-код:

Всего 12 посетителей :: 0 зарегистрированных, 0 скрытых и 12 гостей

Сейчас этот форум просматривают: нет зарегистрированных пользователей и 12 гостей

| Автор | Сообщение | |||||

|---|---|---|---|---|---|---|

|

Заголовок сообщения: iBR отказал на RXP260 код ошибки… СообщениеДобавлено: 16 июн 2013, 17:54 |

||||||

Имя: Александр |

Привет всем! Отказал IBR и выкидывает ошибку. Загорается чек енжин и падают обороты. Коды на форуме и инете не нашел. Подскажите кто знает…! _________________ |

|||||

| Вернуться к началу |

Профиль Ответить с цитатой |

|||||

|

Lexx5 |

||||

Имя: Александр |

А вообще где находится блок управления iBR? Неужели в самой глубокой корме, где и привод? _________________ |

|||

| Вернуться к началу | ||||

|

Raider |

||||

Имя: Юрий |

Lexx5 писал(а): Р1661 помпа |

|||

| Вернуться к началу | ||||

|

Lexx5 |

||||

Имя: Александр |

Да я тоже нашел на форуме что это помпа… Но трюмной помпы у меня нет… И думаю не у кого на RXP нет в штатном варианте… Есть еще варианты? Программеоы, откликнитесь… _________________ |

|||

| Вернуться к началу | ||||

|

kacik_mega@mail.ru |

||||

Техника: rxp 350 |

в 2011 году на rxt — все время ibr глючил, помогало обновление у диллера. _________________ http://stich-shop.ru/ http://rivaracing.ru |

|||

| Вернуться к началу | ||||

|

Lexx5 |

||||

Имя: Александр |

записался на диагностику… как все сделаю — отпишу…! Но меня уже насторожило то, что наши дилеры убили 2 кластера (как они сказали) обновлением… Типа програграммуля стирает старую программу, а потом не находит обновление, а старую уже стерла и уже 2-е приборки отвезли на Москву… Напрягаюсь, но других вариантов пока нет… _________________ |

|||

| Вернуться к началу | ||||

|

Igor60 |

||||

Имя: Игорь |

Как то так _________________ |

|||

| Вернуться к началу | ||||

|

Lexx5 |

||||

Имя: Александр |

Igor60 писал(а): Как то так Игорь, ОГРОМНОЕ СПАСИБО! Форум — сила!!!! Судя по картинкам, я так понял что для начала мне надо проверить разъем на iBR и снять показания с ножек этого разъема..!? Так? _________________ |

|||

| Вернуться к началу | ||||

|

Lexx5 |

||||

Имя: Александр |

Посмотрел парт-каталог, в принципе понятно как снимать, вроде.. . _________________ |

|||

| Вернуться к началу | ||||

|

Igor60 |

||||

Имя: Игорь |

Lexx5 писал(а): Igor60 писал(а): Как то так Игорь, ОГРОМНОЕ СПАСИБО! Форум — сила!!!! Судя по картинкам, я так понял что для начала мне надо проверить разъем на iBR и снять показания с ножек этого разъема..!? Так? Главное что бы помогло _________________ |

|||

| Вернуться к началу | ||||

|

TiHiY |

|

|

Откуда: Алматы |

Lexx5 писал(а): Привет всем! Отказал IBR и выкидывает ошибку. Загорается чек енжин и падают обороты. Коды на форуме и инете не нашел. Подскажите кто знает…! Приветствую! |

| Вернуться к началу | |

|

Lexx5 |

||||

Имя: Александр |

iBR на 77м/ч, а на примерно 15 м/ч выходил из строя датчик температуры воздуха во впускном коллекторе. Стоимость около 3т.р. Не думаю что iBR на RXP болезнь, просто мне повезло больше… _________________ |

|||

| Вернуться к началу | ||||

|

TiHiY |

|

|

Откуда: Алматы |

Lexx5 писал(а): iBR на 77м/ч, а на примерно 15 м/ч выходил из строя датчик температуры воздуха во впускном коллекторе. Стоимость около 3т.р. Не думаю что iBR на RXP болезнь, просто мне повезло больше… спасибо!! |

| Вернуться к началу | |

|

evv777 |

|

|

Имя: Виктор |

Lexx5 писал(а): iBR на 77м/ч, а на примерно 15 м/ч выходил из строя датчик температуры воздуха во впускном коллекторе. Стоимость около 3т.р. Не думаю что iBR на RXP болезнь, просто мне повезло больше… Тогда фартовый ты Санечек. Привет Братуха |

| Вернуться к началу | |

|

evv777 |

|

|

Имя: Виктор |

TiHiY писал(а): Lexx5 писал(а): iBR на 77м/ч, а на примерно 15 м/ч выходил из строя датчик температуры воздуха во впускном коллекторе. Стоимость около 3т.р. Не думаю что iBR на RXP болезнь, просто мне повезло больше… спасибо!! Тогда жди 79. Салам земеля |

| Вернуться к началу | |

Кто сейчас на конференции |

|

Сейчас этот форум просматривают: нет зарегистрированных пользователей и 12 гостей |

| Вы не можете начинать темы Вы не можете отвечать на сообщения Вы не можете редактировать свои сообщения Вы не можете удалять свои сообщения Вы не можете добавлять вложения |

Skip to content

7 Most Common Sea-Doo iBR Problems and Fixes [+ iBR Fault Codes]

Although Sea-Doo’s iBR is a revolutionary system, it’s prone to occasionally failing. The most common iBR problems are caused by one of these issues:

- iBR gate is stuck

- Electrical system malfunctions

- iBR Motor issues

- Computer failure

- iBR Actuator issues

- Cooling system failure

- Brake lever sensor failure

You’ve come to the right place if you want to find out more about these problems and their fixes.

We at JetDrift have compiled them together along with the official iBR fault codes under one roof!

7 Sea-Doo iBR Problems and Their Fixes

The most obvious symptom of an iBR failure is a stuck gate.

Sometimes the gate gets stuck in the folded-up position, but this is still the preferred case. If this happens, the computer shifts into “Limp Home Mode,” allowing you to ride the ski back to the dock at a limited speed.

The worst-case scenario is when the iBR gate is stuck in reverse, preventing the ski from moving forward.

If you see the iBR light flashing on the dashboard, you can ensure that the iBR system is broken. The source of the malfunction can be mechanical, electrical, or even both.

iBR failures can be caused by various errors, but the most common ones are arguable as follows:

- iBR gate is stuck

- Electrical system malfunctions

- iBR Motor issues

- Computer failure

- iBR Actuator issues

- Cooling system failure

- Brake lever sensor failure

Let’s get down to the nitty-gritty and discuss these issues in detail!

1. Sea-Doo iBR Gate is Stuck

It’s safe to say that the most common iBR issue is when the gate gets stuck. In these cases, the system is typically clogged by a small bush branch, gravel, or sand.

The iBR system features several moving units that don’t mix well with these materials.

The thruster control mechanism is especially prone to failure due to a clog. These tracks and rollers are designed to position the gate, so they must operate with extreme precision.

This is why beaching a modern, iBR-equipped Sea-Doo is definitely not recommended.

Instead of beaching, best practice is to keep the Sea-Doo on an anchor a few feet from shore.

Fortunately, a clogged iBR system can be easily cleared in most cases. Just override the iBR system (see our step-by-step tutorial below), flip up the gate, and clean the system.

For safety reasons, it’s highly recommended that you disconnect the battery or remove the iBR fuses before touching the iBR gate.

Keep in mind that the iBR motor is pretty strong and cannot detect that your fingers are in the way if it starts moving the gate.

Besides overriding the system, you could also move the gate up and down by hand by disconnecting the reverse gate from the actuator shaft.

If this doesn’t work, it’s a sign that something is blocking the gate from free movement, and it needs a closer look.

2. Electrical and Battery Malfunctions

One of the drawbacks of the iBR system is that it’s picky about battery voltage and electrical issues.

If your Sea-Doo has an iBR malfunction, you should check the battery voltage and wiring system. Only a loosened battery connection can cause an iBR malfunction!

Best practice is to inspect the wire harness and connectors for corrosion and appropriate contact.

Also, don’t forget to check the iBR fuses in the fuse box, including the IBR control fuse and the iBR power fuse.

If the fuses are good, the battery and the cables/connectors are secure, and the gate moves freely, you should take your ski to a dealer.

The iBR is a complex system and not easy to fix without proper tools and experience.

But if you want to drill into the details, keep reading. We’ve listed the key elements of the system and their most common malfunctions.

3. iBR Motor Issues

The heart of the iBR system is a small but pretty strong electric motor, known as the iBR motor. This little power source is prone to seizing or making a grinding noise in case of a malfunction.

In other cases, it spins freely but can’t provide enough power to swing the reverse gate.

4. iBR Computer Problems

The iBR motor is controlled by an on-board iBR computer; these units are marketed as a single unit.

This computer can also fail due to electrical issues or even a simple jump-start. Due to this risk, jump-starting a modern Sea-Doo is a very bad idea!

5. iBR Actuator Issues

The iBR motor is nestled in a larger unit, known as the iBR actuator (a.k.a. iBR Module or iBR Actuator Module.)

As the name suggests, this module is intended to set the correct position of the iBR gate. Besides the iBR motor, this unit houses many moving parts, including a set of plastic gears, bushings, and a threaded rod.

The assembly is enclosed in black plastic featuring two sealed covers and connected to the gate with the iBR actuator shaft.

When it comes to iBR Actuator issues, the most common problems are broken plastic gears, but the bushings are also prone to burning down.

It’s also wise to check the moving arm for excessive backlash.

6. iBR Cooling System Failure

It’s a lesser-known fact that the iBR system can also overheat under certain conditions.

The iBR cooling system failure always comes with a “Water temperature sensor overheat” fault code, indicating that you must check the iBR cooling circuit.

7. Brake Lever Sensor Failure

The iBR system utilizes a handlebar-mounted iBR lever, also known as the brake lever.

Like the fly-by-wire throttle lever, the iBR lever also features a sensor that sends electric signals to the computer.

Unfortunately, this sensor and its hardware can also fail in many ways.

Sea-Doo iBR Fault Codes

How to Read Sea-Doo iBR Fault Codes

Like any other Sea-Doo fault code, the codes of the iBR system can also be read and cleared by a special diagnostic tool and software. The most well-known tools are BRP’s BUDS system and the brand-independent CandooPro.

If you don’t want to invest in these expensive products, you should head to a local shop or an authorized Sea-Doo dealer.

Sea-Doo iBR Fault Code List

For your convenience, we’ve also compiled the Sea-Doo iBR fault codes into one chart:

| SEA-DOO FAULT CODE LIST | DESCRIPTION | POSSIBLE CAUSE | REPAIR ACTION |

|---|---|---|---|

| C0042 | Brake Lever Sensor (BRLS) signals A open/shorted to ground | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. | Check for 0.5 to 3 V on pin F. and 0.25 to 1.5V on pin C. |

| C0043 | Brake Lever Sensor (BRLS) signals B open/shorted to ground | Damaged sensor, damaged circuit wires, damaged connector or damaged iBR pins. Fault detected when the engine is running or stopped. | Check for 0.5 to 3 V on pin F and 0.25 to 1.5 on pin C. |

| C0073 | Torque request failure | ECM software failure. CPS wires shorted. | Perform ECM software updates if available or replace ECM. Verify CPS connection. |

| C2100 | Sensors calibration is corrupted | Incompatible firmware or memory failure. | Replace the iBR unit. Refer to the Service Manual for more details. |

| C2101 | Actuator movement warning | The reverse gate cannot move to the desired position within the expected time. | Clean and check for damage in the reverse gate and nozzle area. Refer to the Service Manual for more details. |

| C2100 There are a few with the same code. | Actuator movement | The reverse gate cannot move to the desired position. | Clean and check for damage in the reverse gate and nozzle area. Refer to the Service Manual for more details. |

| C2110 | Reverse gate position sensor error | iBR malfunction. | Check for correct movement of iBR.Replace the iBR unit. Refer to the Service Manual for more details. |

| C2110 | Angle position sensor warning | iBR malfunction. | Replace the iBR unit. Refer to the Service Manual for more details. |

| C2110 | iBR overheat | iBR cooling system failure. iBR unit failure. | Check the iBR cooling circuit. Replace the iBR unit. Refer to the Service Manual for more details. |

| C2110 | Monitoring CPU message timeout or validity | iBR malfunction. | Perform an iBR software update if available. Replace the iBR unit. Refer to the Service Manual for more details. |

| C2110 | Monitoring CPU limp force | iBR malfunction. | Perform an iBR software update if available. Replace the iBR unit. Refer to the Service Manual for more details. |

| C2111 | ECM erratic RPM signal | RPM signal received from engine ECM not plausible | Check CPS sensor connection |

| C2120 | Application calibration is corrupted | Incompatible firmware or memory failure. | Perform an iBR software update if available. Replace the iBR unit. Refer to the Service Manual for more details. |

| C2121 | Application parameters corrupted (backup #1 or #2) | Battery power loss or memory failure. | Perform an electrical system shut download to clear the fault. Verify starting and charging system circuits. Refer to the Service Manual for more details. |

| 2122 | The last session interrupted | Unexpected battery power lost. | Perform an electrical system shut down and clear fault. Verify starting and charging system circuits. Refer to the Service Manual for more details. |

| C2130 | Motor current software breaker | Motor current too high. | Clean and check for damage in the reverse gate and nozzle area. Refer to the Service Manual for more details. |

| C2130 | Internal motor drive failure | Motor voltage feedback not fitting with the command. | Check that the power cable to the motor is connected |

| C2131 | iBR DC motor shorted to ground or 12 V | iBR motor failure. iBR motor wires damaged or moisture detected | Check iBR circuits A and B. Refer to the Service Manual for more details. |

| C2132 | Motor Open | No current while activated. | Check the power cables are connected. |

| C2142 | Brake Lever Sensor (BRLS) signals A shorted to battery | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. | Check for 0.5 to 3 V on pin F and 0.25 to 1.5 on pin C. |

| C2143 | Brake Lever Sensor (BRLS) signals B shorted to battery | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. | Check for 0.5 to 3 Von pin F and 0.25 to 1.5 on pin C. |

| C2144 | Brake Lever Sensor (BRLS) power shorted to battery | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. | Check for 4.5 to 5 volts on sensor connector pin A & D. Refer to the Service Manual for more details. |

| C2145 | Brake Lever Sensor (BRLS) power shorted to ground | Damaged sensor, damaged circuit wires, damaged connector, or damaged iBR pins. Fault detected when the engine is running or stopped. | Check for 4.5 to 5 volts on sensor connector pin A & D. Refer to the Service Manual for more details. |