Hi Guys, my 2ND post i got the BMW Scanner Ediabas/INPA 4 compatible OBD2 Interface UK — from ebay — serial connection(not USB)

I Have a BMW 120d — SE — 2007 — i think its a E87? — Computer is HP6220 — XP SP3 — NO VMWARE, installed locally.

I cannot get INPA to talk to my car installed 4 differnet installs(ghosting machine each time back to original state) followed different guides. This is what i have concluded to be common to all the installs i have seen.Installed as instructed — INPA 5.02 — EDIABAS — 6.4.7

and made the following changes after install.

YOU WILL GET ISSUES IF YOU DO NOT COPY FILES FROM CD TO THE ROOT DRIVE OF C:INPA BEFORE INSTALLING AT THE BEGINNING.

AND RUN FROM c:|inpa ISSUES START WHEN YOU GET TO THE CHOOSING WHAT TO INSTALL.

aNY WAY AFTER INSTALL:-1

EDIABAS.INI

Lives in

C:EDIABASBin

;——————————————————————————

; Interface

; Description : Connected diagnosis interface

; Default = STD:OBD

Interface =STD:OBD

; Additional information (in German) :

; Bitte beachten: Der HW-Treiber fuer das Interface muss installiert sein!

; Interface = STD:OBD

; Beschreibung : Serieller Pegelwandler (Nachfolger von ADS / Anschluss an OBD-Dose)

; Installation : EDIABASHARDWAREOBDODBSETUP (nur noetig fuer WIN NT4, WIN 2000, WIN XP)

———————————————————————————

2Right Click — my computer- — device manager — ports — com1 — port setting — advancd — fifo buffers ticked — and TX and RX set to 8 — OK to save

—————————————————

3Right Click — my computer- sytem properties — advanced —

Environment Variables — system Variables — find the PATH one in the list highlight and EDIT — add this to the end of the paths(NO SPACES but remove quotes)»;C:EDIABASBin;C:INPABIN»—————————————————

4THE OBD.ini — lives in C:EDIABASBin — well on some installs or can be created manually.

EDIT OBD.ini — copy to windows directory — C:WINDOWS

[OBD]

Port=Com1

Hardware=OBD

RETRY=ON

;Tracelevel=0xFFFFFFFF

;Tracelevel=0xFFFFFFFF

;Tracelevel=0xF0000000

;Tracelevel=0x0000FFFF

; Bit 0 = Funktionsaufruf

; Bit 1 = io Ergebnis

; Bit 2 = nio Ergebnis

; Bit 3 = Detailinfos

; Nibble 0 = readchar_wait

; Nibble 1 = main

; Nibble 2 = cmd

; Nibble 3 = obd

; Nibble 4 = send_and_receive_…

; Nibble 5 = read_telegram_…

; Nibble 6 = send_telegram

; Nibble 7 = SendData

—————————

5Run the OBDSetup.exe in the C:EDIABASHardwareOBD to update the registry for OBD settings and then reboot re run the above and all should show OK.

————————————————

6Ensure you run the INPALOAD.exe — from C:EC-APPSINPABIN — WHEN USING INPA

————————————————————Note.

In INPA i do get the Battery black circle and ignition when turned on black circle but i have had numerous errors when testing i select E87 — status Busy then i get — from IFH-0009 — SYS-0005 — API etc i have checked these in the INPA-FAQ.pdf. I have copied contents from

Any Help would be appreciated — i think it must be an .ini or something.

Thanks in advance.Firstly Guys — thanks for your reply at BMWLAND — I checked the SGBD folder doesn’t exist — so i put it there.

ODB.ini put in the sysyem and system32 folder(although the path in the env variable points to this.)

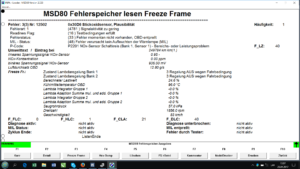

As can be seen from the screen shot the lead is sensing the connection — maybe «minesavolvo» is correct in the fact that i do not have the correct files for the E87?? i have attached the DIR of the entire c’drive hope someone can point me in the right direction — man hours is shooting through the roof.lol

«TheEnd» — you were correct the OBD.ini was a little short i did so to keep the page shorter.

EDIABAS.ini — underlined the OBD bit — I’m also wondering why it shows E89 in the INPA window under model?? is it the same as E87.

As always thanks for your help.;================================================= ============================

;EDIABAS 6.4.3 Configuration

[Configuration]

;================================================= ============================;——————————————————————————

; EcuPath

; Description : ECU file path

; Default = .

EcuPath = C:EDIABASEcu;——————————————————————————

; SimulationPath

; Description : Simulation file path

; Default = .

SimulationPath = C:EDIABASSIM;——————————————————————————

; TracePath

; Description : Trace file path

; Default = .

TracePath = C:DiagProgTrace;——————————————————————————

; CodeMapping

; Description : Character mapping file path

; Default = .

;CodeMapping = C:EDIABASBINansi2oem.tab;——————————————————————————

; TraceSize

; Description : Maximum size of each trace file [KB]

; Value : 0..32767

; Default = 1024

TraceSize = 5120;——————————————————————————

; ApiTrace

; Description : Enable/Disable API/User trace

; Value : 0 = Trace disabled

; 1 = User trace

; 2 = User trace + time stamp

; 3 = User trace + time stamp + process id (Win32)

; 4 = Function trace

; 5 = Function trace + time stamp

; 6 = Function trace + time stamp + timing

; 7 = Function trace + time stamp + timing + process id (Win32)

; Default = 0

ApiTrace = 0;——————————————————————————

; IfhTrace

; Description : Enable/Disable IFH trace

; Value : 0 = Trace disabled

; 1 = Trace enabled

; 2 = Trace enabled

; 3 = Trace enabled

; Default = 0

IfhTrace = 0;——————————————————————————

; SystemTraceSys

; Description : Enable/Disable system trace (runtime system)

; Value : 0 = Trace disabled

; Trace levels 1..7

; Default = 0

SystemTraceSys = 0;——————————————————————————

; SystemTraceBip

; Description : Enable/Disable BIP trace (runtime system)

; Value : 0 = Trace disabled

; Trace levels 1..7

; Default = 0

SystemTraceBip = 0;——————————————————————————

; SystemTraceIfh

; Description : Enable/Disable IFH system trace

; Value : 0 = Trace disabled

; Trace levels 1..7

; Default = 0

SystemTraceIfh = 0;——————————————————————————

; SystemTraceNet

; Description : Enable/Disable network trace

; Value : 0 = Trace disabled

; Trace levels 1..7

; Default = 0

SystemTraceNet = 0;——————————————————————————

; BipDebugLevel

; Description : BIP debug level of ECU files

; Value : 0..32767

; Default = 0

BipDebugLevel = 0;——————————————————————————

; UbattHandling

; Description : Ubatt ON/OFF handling

; Value : 0 = Ubatt ON/OFF: No EDIABAS error

; 1 = Ubatt ON/OFF: EDIABAS error

; Default = 1

UbattHandling = 0;——————————————————————————

; IgnitionHandling

; Description : Ignition ON/OFF handling

; Value : 0 = Ignition ON/OFF: No EDIABAS error

; 1 = Ignition ON/OFF: EDIABAS error

; Default = 1

IgnitionHandling = 0;——————————————————————————

; TaskPriority

; Description : EDIABAS process/thread priority (only Win32/16)

; Value : 0 = Optimal EDIABAS performance = 8

; 1 = Minimal EDIABAS performance

; ..

; 10 = Maximal EDIABAS performance

; Default = 0

TaskPriority = 0;——————————————————————————

; LoadWin32

; Description : Map EDIABAS Win16 calls to EDIABAS Win32

; Value : 0 = Win16/32 Mapping disabled (Win16—>Win16)

; 1 = Win16/32 Mapping enabled (Win16—>Win32)

; Default = 0 for Windows 9x/Me

; Default = 1 for Windows NT4/2000/XP

;LoadWin32 = 0;——————————————————————————

; SystemResults

; Description : Enable/Disable system results (ubatt/ignition/jobstatus)

; Value : 0 = Disable system results

; 1 = Enable system results

; Default = 1

SystemResults = 1;——————————————————————————

; RetryComm

; Description : Repeat failed communication automatically (1x)

; Value : 0 = Retry disabled

; 1 = Retry enabled (1x)

; Default = 1

RetryComm = 1;——————————————————————————

; Simulation

; Description : Enable/Disable ECU simulation

; Value : 0 = Simulation disabled

; 1 = Simulation enabled

; Default = 0

Simulation = 0;——————————————————————————

;

; Description : Connected diagnosis interface

;Default = OBD

Interface = STD:OBD

; Additional information (in German) :

; Bitte beachten: Der HW-Treiber fuer das Interface muss installiert sein!; Interface = STD:OBD

; Beschreibung : Serieller Pegelwandler (Nachfolger von ADS / Anschluss an OBD-Dose)

; Installation : EDIABASHARDWAREOBDODBSETUP (nur noetig fuer WIN NT4, WIN 2000, WIN XP)

; INI-Datei : OBD.ini nur benutzt wenn im Windows-Verzeichnis

; Unterstuetzung : WIN3.xx : Nein

; WIN95,98 16-Bit : Ja

; WIN95,98 32-Bit : Ja

; WIN NT 4.0 : Ja

; WIN XP : Ja; Interface = STD:FUNK

; Beschreibung : Funk-Diagnose Interface MDA von Fa. Siemens

; Installation : keine

; INI-Datei : FUNK.INI

; Unterstuetzung : WIN95,98 16-Bit : Ja

; WIN95,98 32-Bit : Ja

; WIN NT 4.0 : Ja

; WIN XP : Ja; Interface = ADS

; Beschreibung : Serieller Pegelwandler (Anschluss an Diagnose-Dose)

; Installation : EDIABASHARDWAREADSADS32ADSSETUP (nur fuer WinNT4 noetig)

; INI-Datei : keine

; Unterstuetzung : WIN95,98 16-Bit : Ja

; WIN95,98 32-Bit : Nein

; WIN NT 4.0 : Ja

; WIN XP : Ja; Interface = KBUS

; Beschreibung : Serieller Pegelwandler (Anschluss direkt an K-Bus oder I-Bus)

; Installation : EDIABASHARDWAREADSADS32ADSSETUP (nur fuer WinNT4 noetig)

; INI-Datei : keine

; Unterstuetzung : WIN95,98 16-Bit : Ja

; WIN95,98 32-Bit : Nein

; WIN NT 4.0 : Ja

; WIN XP : Ja; Interface = EDIC

; Beschreibung : Serielles , PCMCIA , PC-Card Interface von Fa. Softing

; Installation : EDIABASHARDWAREEDICSETUP.EXE

; INI-Datei : EDICFW.INI, EDICHW.INI

; Unterstuetzung : WIN95,98 16-Bit : Ja

; WIN95,98 32-Bit : Ja

; WIN NT 4.0 : Ja

; WIN XP : Ja; Interface = EDICC

; Beschreibung : EDIC-Card C oder EDIC-Card 2 CAN-Interface von Fa. Softing

; Installation : EDIABASHARDWAREEDICSETUP.EXE

; INI-Datei : XEDICC.INI

; Unterstuetzung : WIN95,98 16-Bit : Ja

; WIN95,98 32-Bit : Ja

; WIN NT 4.0 : Ja

; WIN XP : Ja; Interface = STD:CAN

; Beschreibung : PCMCIA CAN-Interface CanCardX von Fa. Vector

; Installation : keine (ausser Installation der CAN-Karte)

; INI-Datei : CANRTTP.INI

; Unterstuetzung : WIN95,98 16-Bit : ?

; WIN95,98 32-Bit : ?

; WIN NT 4.0 : Ja

; WIN XP : ?

; Ansprechpartner: Hr. Jusko

; Telefon : +49-(0)89/382-35891 (Hotline)

; email :FLASH.SERVICE@BMW.DE (Hotline)

; Interface = STD:ADS4MOST

; Beschreibung : Most-Interfaces von Fa. Oasis

; Installation : keine (ausser Installation der Oasis-Karte)

; INI-Datei : ADS4MOST.INI

; Unterstuetzung : WIN95,98 16-Bit : ?

; WIN95,98 32-Bit : ?

; WIN NT 4.0 : Ja

; WIN XP : Ja

; Ansprechpart.: Hr. Rowedder

; Telefon : 089 / 382-29159

; email :Michael.Rowedder@bmw.de

; Interface = REMOTE

; Beschreibung : Anbindung eines EDIABAS-Interfaces �ber TCP/IP

; Installation : Anpassung der Eintr�ge in [TCP] auf beiden Seiten (ins.: RemoteHost, Port)

; INI-Datei : keine

; Unterstuetzung : WIN95,98 16-Bit : Nein

; WIN95,98 32-Bit : Ja

; WIN NT 4.0, XP : Ja

; WIN XP : Ja

; Sonderfall : Interface OPPS

; Ansprechpart.: Hr. Rowedder

; Telefon : 089 / 382-29159

; email :Michael.Rowedder@bmw.de

; Interface = REMOTE:name

; Beschreibung : Anbindung eines EDIABAS-Interfaces �ber TCP/IP

; Installation : Anpassung der Eintr�ge in [TCP] auf beiden Seiten (ins.: RemoteHost, Port)

; INI-Datei : REMOTE.INI (insbesondere f�r Parallelbetrieb notwendig)

; In REMOTE.INI stehen unter [name] spezif. Einstellungen(z.B.: RemoteHost, Port)

; Unterstuetzung : WIN95,98 16-Bit : Nein

; WIN95,98 32-Bit : Ja

; WIN NT 4.0, XP : Ja

; WIN XP : Ja

; Sonderfall : Interface OPPS

; Ansprechpart.: Hr. Rowedder

; Telefon : 089 / 382-29159

; email :Michael.Rowedder@bmw.de

;——————————————————————————

; NetworkProtocol

; Description : Network protocol

; Default =

NetworkProtocol = TCP;================================================= ============================

;TCP/IP Configuration

[TCP]

;================================================= ============================;——————————————————————————

; RemoteHost

; Description : server address/name

; Default =

RemoteHost = WMUC102911;——————————————————————————

; Port

; Description : IP communication port

; Value : 1000 < port < 30000

; Default =

Port = 3000;——————————————————————————

;TimeoutConnect

; Description : Timeout for establishing the connection

; Default = 5000

TimeoutConnect = 2000;——————————————————————————

;TimeoutReceive

; Description : Timeout for receiving a message

; Default = 5000

TimeoutReceive = 2000;——————————————————————————

;TimeoutFunction

; Description : Timeout for a long function

; Default = 59000

TimeoutFunction = 10000;——————————————————————————

;DisconnectOnApiEnd

; Description : Enable/Disable Disconnection with function call ApiEnd

; Value : 0 = Disconnection disabled

; 1 = Disconnection enabled

; Default = 0

;DisconnectOnApiEnd = 1;——————————————————————————

;InitCmd<n>

; Description : Initialization command <n> (normally for OPPS)

; Default =

;InitCmd0 = FE,04,00,03,01

;InitCmd1 = FD,05,00,03,01;================================================= ============================

; End Of File EDIABAS.ini

;================================================= ============================

In this article I will share solutions of BMW INPA Errors,belows list 12 errors of BMW INPA when installing BMW INPA Software.Hope it is helpful!

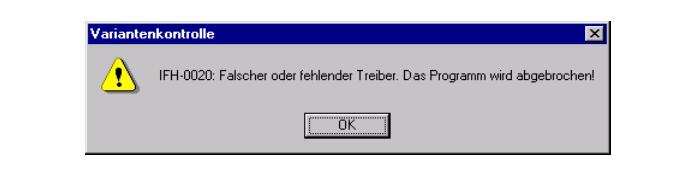

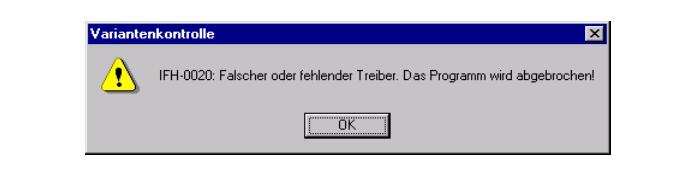

Error Message 0020: Incorrect or Missing Driver. The programme will be aborted!

Conditions:

You have access to \smuc0900sg . You are linked to this drive and would like to start an INPA script.

Reason 1: Missing Ediabas.ini file in C:Winnt.

Reason 2: You are not connected to the controller.

For developers: Simulation is not switched on in the Ediabas.ini file.

Solution: Copy the Ediabas.ini file from C:EdiabasBin to C:Winnt.

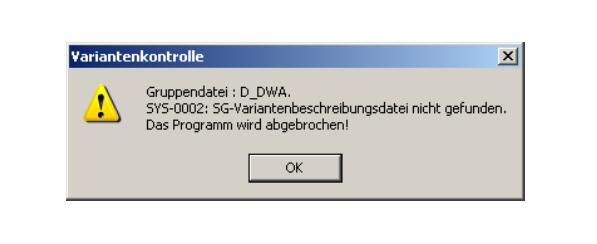

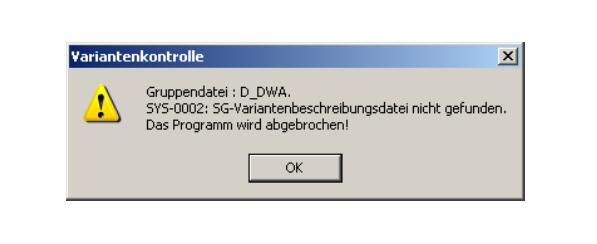

SYS-00002: ECU variation description file not found.

The error occurs when starting an INPA script.

Reason 1: The *.prg SGBD is not located in the path C:EdiabasEcu.

Solution 1: Copy the *.prg SGBD into the ECU directory.

Reason 2: The external table T_GRTB.prg doesn’t exist in the directory C:EDIABASECU

or it is obsolete.

Solution 2: Copy the file into the ECU directory or update the external table using the ECCO

Web Client.

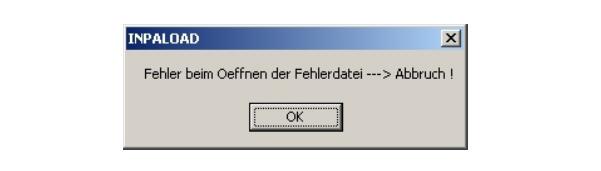

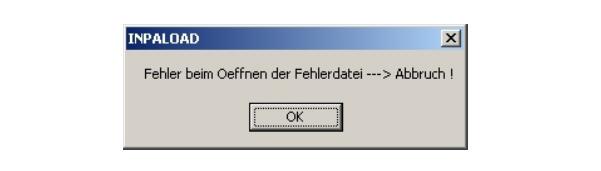

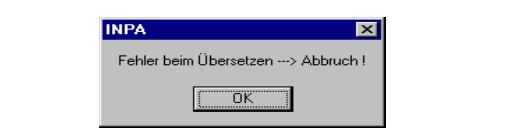

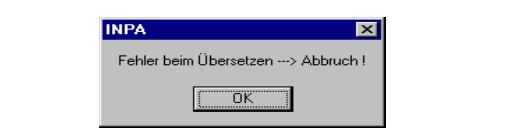

INPA Error: Error at Compiling Abort!

The following error message appears when starting an INPA script.

Reason 1: An INPA script with the ending IPO was started by the programme INPA.EXE

instead of by the programme INPALOAD.EXE.

Solution 1: Only start INPA scripts that end with IPO with INPALOAD.EXE.

Reason 2: The selected INPA script doesn’t exist in the C:INPASGDAT directory.

Solution 2: Update the INPA scripts using the ECCO Web Client.

Reason 3: INPA Version 5.0.1: The INPA script *.IPO can’t be started with a double-click in

the directory C:INPASGDAT*.IPO.

Solution 3: Update to Version 5.0.2.

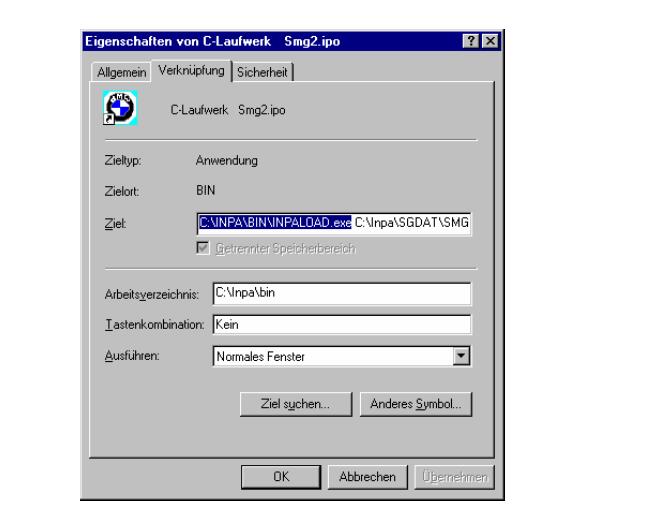

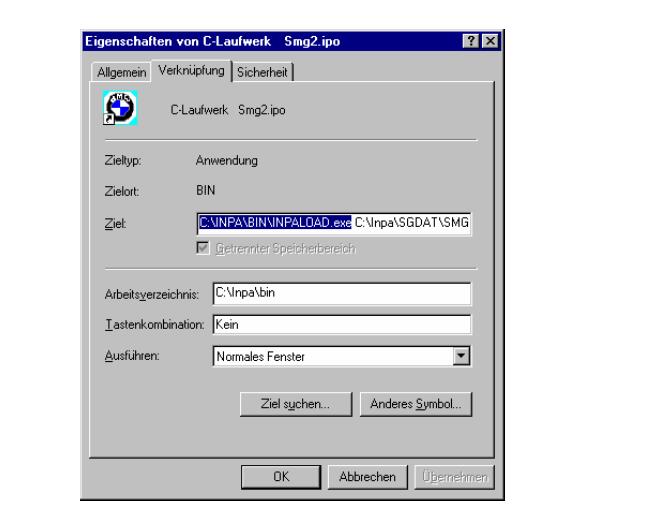

Reason 4: INPA Version 5.0.1: The desktop link of an INPA script doesn’t work.

Solution 4: The target path must be expanded to include the INPALOAD path. To do this,

click the desktop link once with the right mouse button and go to ‘Properties’.

Expand the target path to include C:INPABININPALOAD.exe for Windows NT

(see Fig.) and C:EC-AppsINPABININPALOAD.exe for Windows XP.

Reason 5: The file startger.ipo of the german installation and the file startus.ipo of the

english installation don’t exist in the directory INPACFGDAT.

Solution 5: Install INPA once again.

IFH-0018: Inizialisation Error – INPA doesn’t work but Toolset yet

The error occurs if a SGBD is running by INPA or CASCADE. If the same SGBD is loaded in

the Toolset it will not occure an inizialisation error.

Reason 1: The communications port COM1 doesn’ exist, but COM3 yet. The Toolset is

working without the inizialisation error, because the file OBD.ini exists in the

directory C:Ediabasbin. But the file OBD.ini has to exist in the direcory

C:Windows.

Solution 1: Copy the file OBD.ini in the directory C:Windows or create a new one. (Creation

of OBD.ini q.v. 3.3).

Reason 2: q.v. 3.3

Solution 2: q.v. 3.3

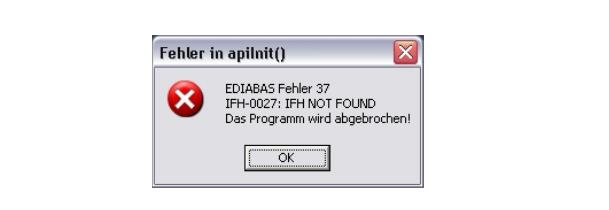

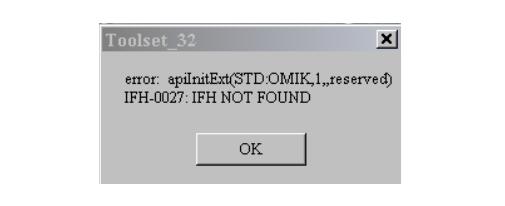

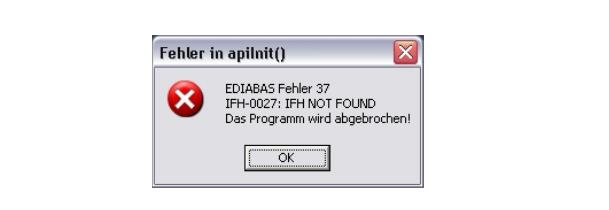

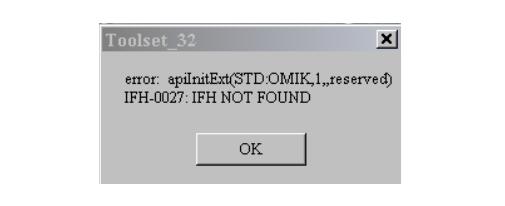

IFH-0027: IFH not found The Programm was aborted!

The error occurs when starting INPA.

Reason 1: The setting for the interface in the configuration file Ediabas.ini doesn’t exist.

Solution 1: Please do the settings for the interface e.g.:

Interface = STD:OBD

Reason 2: The setting for the interface in the configuration file Ediabas.ini is

Interface=STD:OMITEC, but the OMITEC driver isn’t installed correctly.

Solution 2: Install the OMITEC driver with the instructions

InstructionforOMITECInstallation.pdf via the GIS server.

Reason 3: The setting for the interface in the configuration file Ediabas.ini is

Interface=OMITEC, but the correct setting is Interface=STD:OMITEC.

Solution 3: Please do the settings for the interface Interface=STD:OMITEC.

Reason 4: The old OMITEC driver wasn’t uninstalled correctly.

Solution 4: Please uninstall the old OMITEC driver with the instructions

InstructionforOMITECInstallation.pdf via the GIS server.

INPA Error: Opening Inpa – Transmission error returned a_0x2

Reason: During the installation of Ediabas/Inpa, the configuration “Without configuration”

was selected.

Solution: When running the installation programme, select a configuration, e.g. “BMW

Plant 1.1 Munich”.

INPA Error: Only a white screen appears when you run INPALOAD.EXE.

Reason 1: The api.dll or api32.dll file has been manually copied into the WINDOWS

directory with Windows XP and into the WINNT directory with Windows NT.

Solution 1: Delete the file api.dll or alternatively api32.dll from the WINDOWS or alternatively

the WINNT directory. The file may only exist in the directory EDIBASBIN.

Reason 2: You have installed the 32-bit version of INPA (as of Version 5.0.1) and have not

performed an update of the INPA scripts.

Solution 2: Update the INPA scripts using the ECCO Web Client.

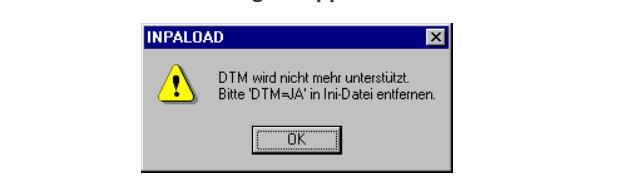

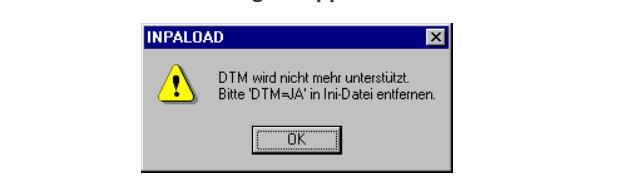

INPA Error: DTM is no longer supported

Reason: This error message appears if INPA.INI has been copied from Version 4.7.7 to

Version 5.x.x.

Solution: Since it can’t be excluded that even more files from the old version have been

mixed with the new ones, the old ones must be deleted, or alternatively

reinstalled (see Chapter 5). Reinstall INPA using the Global Information Service

(GIS) https://gis.bmw.com.

INPA Error: Bridge16.exe can’t be initialised

Reason 1: A 16-bit INPA script has been started with the 32-bit version of INPA (as

of Version 5.0.1).

Solution 1: Update the INPA scripts using the ECCO Web Client.

Solution 2: Convert the INPA script to the standard ‘includes’ for the 32-bit version.

To do this, contact the respective person responsible for INPA at TI-43x

(see \smuc0900sgrefReferenzReferenz.inp)

Reason 2: A 16-bit DLL has been found, which means the developer of the INPA

script is using a 16-bit DLL.

Solution 2: The developer of the INPA script must convert the DLL to 32-bit.

Error when opening the error file abort:

Reason: This error occurs with Windows XP because the user doesn’t have the correct

rights to change files in the directory C:INPABin.

Solution: The user needs “Power user” rights or the user needs the appropriate write rights

to the “INPA” directory.

Compiler: File: INPADEUTSCH***.OUT not found!

Reason: The path C:EDIABASBIN has not been set in the ‘Path’ system variable.

Solution: Set the path C:EDIABASBIN in the ‘Path’ system variable. (q.v. chapter 2.1).

(Visited 102 times, 1 visits today)

BMW INPA how to use- with frequently asked questions:

INPA EDIABAS download:

Inpa diver.zip (unknown security)

Inpa 5.0.1.zip (unknown security)

Inpa 5.0.2.zip (tested & worked on Windows XP)

INPA cable: K+DCAN cable switch mode:

http://www.obdexpress.co.uk/wholesale/new-bmw-inpa-kcan-with-ft232rq-chip-with-switch-expressuk.html

Old K+Dcan cable vs K+DCAN cable switch mode:

2018 New BMW K+Dcan cable with switch vs. Old INPA Dcan cable

Credits to BMW Group!

I take no credit for composing the package, just sharing it

Table of Contents

1. EDIABAS Error Messages …………………………………………………………………………………. 4

1.1 Driver Error……………………………………………………………………………………………………. 4

1.2 DirectNt.sys can’t be opened……………………………………………………………………………. 4

1.3 IFH-0002: Interface isn’t connected or doesn’t respond………………………………………… 4

1.4 IFH-0003: Data transmission HOST/Interface failed…………………………………………….. 4

1.5 IFH-0010: Data transmission to control unit disturbed ………………………………………….. 5

1.6 IFH-0013: Command not implemented………………………………………………………………. 5

1.7 Error: EBAS32.EXE not found or illegal version! …………………………………………………. 5

1.8 EDIABA error: Error (95) SYS-0005: OBJECT FILE NOT FOUND ………………………. 6

1.9 Createfile_error: OPEN CONNECTION; IFH 0018- INITIALIZATION ERROR…………. 6

1.10 Battery and Ignition not recognised …………………………………………………………………… 6

1.11 Warning when starting OBD Setup……………………………………………………………………. 7

1.12 ERROR C1015: Too Many String Variables in Job………………………………………………. 8

1.13 Failure: EDIABAS Fehler 159, NET-0009: TIMEOUT…………………………………………… 8

1.14 Failure: The name of the file or folder can’t be changed……………………………………….. 9

2 Error Message INPA ………………………………………………………………………………………… 10

2.1 APLDLL or API32.DLL can’t be found. …………………………………………………………….. 10

2.2 Error Message 0020: Incorrect or Missing Driver. The programme will be aborted!…. 12

2.3 SYS-00002: ECU variation description file not found………………………………………….. 12

2.4 INPA Error: Error at Compiling à Abort! ………………………………………………………….. 13

2.5 IFH-0018: Inizialisation Error – INPA doesn’t work but Toolset yet ……………………….. 14

2.6 IFH-0027: IFH not found à The Programm was aborted! …………………………………… 14

2.7 INPA Error: Opening Inpa – Transmission error returned a_0x2 ………………………….. 15

2.8 INPA Error: Only a white screen appears when you run INPALOAD.EXE. …………….. 15

2.9 INPA Error: DTM is no longer supported ………………………………………………………….. 16

2.10 INPA Error: Bridge16.exe can’t be initialised …………………………………………………….. 16

2.11 Error when opening the error file à abort:………………………………………………………… 17

2.12 Compiler: File: INPADEUTSCH***.OUT not found! …………………………………………. 17

3 Tool Set Error Messages …………………………………………………………………………………. 18

3.1 EDIABAS error 100: SYS-0010: INITIALIZATION ERROR …………………………………. 18

3.2 EDIABAS Error 126 (only up to Ediabas V6.4.x)………………………………………………… 18

3.3 IFH-0006: Command not accepted and IFH-0018: Initialization Error and IFH-0038:

Interface Command not implemented………………………………………………………………. 18

3.4 IFH-0006: Command not accepted………………………………………………………………….. 19

3.5 IFH-0009: ECU isn’t connected or doesn’t respond……………………………………………. 20

3.6 SYS-0002: ECU OBJECT FILE NOT FOUND…………………………………………………… 20

3.7 SYS-0005: Controller description file not found. The programme will be aborted! …… 20

3.8 ToolSet Error: Runtime error ’372’…………………………………………………………………… 21

3.9 Tool Set Error: Run-time error ’5’ – Invalid Procedure Call ………………………………….. 21

3.10 Tool Set Problem: If an SGBD is opened, then only the hourglass appears and the

SGBD is not loaded. ……………………………………………………………………………………… 21

3.11 EDIABAS error 20: IFH-0010: Data transmission to control unit disturbed …………….. 21

3.12 EDIABAS Error 134: API-0014: Result not found ………………………………………………. 22

3.13 It takes too long to load an SGBD in the Tool Set ……………………………………………… 22

3.14 Black Windows in the Tool Set ……………………………………………………………………….. 22

4 General Questions

………………………………………………………………………………………….. 23

4.1 Installation of EDIABAS and INPA…………………………………………………………………… 23

4.2 xBD-Export of SGBDs, Group SGBDs, INPA scripts and INPA configuration files using

the ECCO Web Client …………………………………………………………………………………… 23

4.3 How can I find out if the serial interface COM1 has been taken?………………………….. 25

4.4 How do I start INPA?…………………………………………………………………………………….. 26

4.5 How can I switch between OBD and ADS interfaces? ………………………………………… 26

4.6 In which directory structure is OBD.ini saved?…………………………………………………… 27

4.7 How can I find out what interface I installed with INPA? ……………………………………… 27

4.8 How do I find out what EDIABAS package is installed?………………………………………. 27

4.9 How can I uninstall EDIABAS or INPA?……………………………………………………………. 27

4.10 How can tell if the EDIABAS server is running as a 16-bit or a 32-bit application? ….. 27

4.11 What is the difference between EDIABASbinToolSet.exe and

EDIABAbinTool32.exe?………………………………………………………………………………. 28

4.12 What is an SGBD and what is its connection to EDIABAS? ………………………………… 28

4.13 Where are the individual SGBD names and their meanings given in plain English?… 28

4.14 What is a Job? …………………………………………………………………………………………….. 28

4.15 What do SGBDs with the name _xxx mean?…………………………………………………….. 29

4.16 What is the group file used for?………………………………………………………………………. 29

4.17 Diagnostics Index …………………………………………………………………………………………. 29

4.18 Variation Index …………………………………………………………………………………………….. 29

4.19 What is the meaning of the file EDIABAS.ini? …………………………………………………… 29

4.20 How is the simulation file connected to the trace file?…………………………………………. 31

4.21 Why have an XBD Generator? ……………………………………………………………………….. 31

4.22 What are the prerequisites for remote access via TCP/IP? …………………………………. 31

4.23 What is the VC Tool and when is it used? ………………………………………………………… 32

4.24 What is the KVP Editor?………………………………………………………………………………… 32

1. EDIABAS Error Messages

1.1 Driver Error

Message comes along with an ADS or OBD connector.

This error occurs if another program or device has taken the COM1 port of your PC.

If you want to work with EDIABAS or INPA, please make sure that the COM1 port is not

taken.

1.2 DirectNt.sys can’t be opened

This error only occurs with an NT computer if the ADS driver hasn’t been installed.

The instructions for installing the ADS driver can be found in the “Installation Guide/Update

Guide” ADS_DOKU.pdf in the directory C:EDIABASHardwareADS or on the Intranet page

http://www5.muc/ti4-web/ti-430/german/themen/Diagnose.htm.

1.3 IFH-0002: Interface isn’t connected or doesn’t respond

Reason: In the Ediabas.ini file, the interface is set to STD:FUNK. However, you have

connected an ADS or OBD connector.

Solution: Modify the interface setting in Ediabas.ini.

1.4 IFH-0003: Data transmission HOST/Interface failed

Reason 1: In the Ediabas.ini file, the interface is set to STD:OBD. However, you have

connected an ADS connector.

Solution 1: Modify the interface setting.

Reason 2: The data transmission failed when sending (e.g. short circuit in the line).

Solution 2: Get rid of the short circuit, for example.

Reason 3: Connector not connected or no power supplied.

Solution 3: Check whether the connector is connected and is supplied with power.

Reason 4: The device manager has been used to disable the FIFO buffer for COM1.

Solution 4: In the device manager (Windows XP: Enter “Start” à “Control Panel” à

“System” à “Hardware” à “Device Manager” à Ports (COM & LPT)), and then

select COM1 from the ports. Then under the “Port Settings” tab, select

“Advanced”. There must be a check-mark by “Use FIFO buffers” and “8” must be

selected for the receive buffer and transmit puffer.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 5 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

1.5 IFH-0010: Data transmission to control unit disturbed

This problem can occur with XP computers with the OBD interface.

Reason: With Windows XP, it is not possible to automatically set the receive and transmit

buffers using OBDSetup.exe, like in Windows NT.

Solution: Set the receive and transmit buffers to 8 as shown in the following:

Use Start à My Computer à Control Panelà System à Hardware à Device

Manager à Ports (COM & LPT) and then click with the right mouse button to call

up the properties of the COM port that is being used. Under the Port Settings tab,

set the Data bits of the receive and transmit buffers to 8.

1.6 IFH-0013: Command not implemented

Reason: The error was caused by another programme that accessed the COM1 interface.

Usually, the “HotSync” programme is installed on the computer for the organiser.

Solution: Check the programmes that are started automatically when Windows is started.

1.7 Error: EBAS32.EXE not found or illegal version!

This error occurs if the path variable is set with the path C:EDIABASBIN in the system and

user variables (Start à My Computer à Control Panel à System à Advanced and then in

the “Environment“ tab).

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 6 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

1.8 EDIABAS error: Error (95) SYS-0005: OBJECT FILE NOT FOUND

Reason 1: No SGBD in C:EDIABASECU

Solution 1: Copy the SGBD into the Ecu directory.

Reason 2: No group file in C:EDIABASECU (for group call)

Solution 2: Copy the group file to C:EDIABASECU

Reason 3: No path definition C:EDIABASBIN

Solution 3: Set the system variable (see 2.1)

Reason 4: Incorrect path definition in EDIABAS.INI

Solution 4: Set the EcuPath path in Ediabas.ini to C:EDIABASECU

Reason 5: The SGBD name contains reserved characters or is too long. Only 8 characters

are allowed (a-z, A-Z, 0-9, “_”).

1.9 Createfile_error: OPEN CONNECTION; IFH 0018- INITIALIZATION

ERROR

ADS Interface:

The following error appears when Ediabas is started: Createfile_error: OPEN

CONNECTION

OBD Interface:

The following error appears when Ediabas is started: Error 28: IFH 0018- INITIALIZATION

ERROR. (Also see Section 3.3)

Reason: Ediabas is attempting to access port COM1. However, the port doesn’t exist, or it

has been taken by another programme (e.g. HotSync from Palm, infrared).

Solution: Install a COM1 interface or free it.

1.10 Battery and Ignition not recognised

Reason: With a Dell Latitude D600 laptop, pin 9 has no function and it is therefore not

able to correctly recognise the battery status.

Solution 1: Use OBD via USB, see C:EDIABASBININI.PDF Chapter 2.2 for this.

Solution 2: The laptop is connected to the docking station.

Solution 3: Workaround for the OBD driver as of February 2004: A file “OBD.ini” must be

created in the directory C:WINDOWS for Windows XP, or alternatively

C:WINNT for Windows NT, with the following entry. This is because with

UBATT=OFF, the battery status is not determined via hardware, but is

permanently set to “Battery voltage available”. Also see OBD_DOKU.pdf in the

EdiabasHardwareOBD directory.

Entry in OBD.ini:

[OBD]

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 7 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

UBATT=OFF

1.11 Warning when starting OBD Setup

A warning occurs when starting C:EDIABASHARDWAREOBDOBDSetup.exe. After You

want to start Tool Set or INPA You will get the following error message:

Reason: The value of the variable DWORD (here RxFIFO) can not be set by

OBDSetup.exe.

Solution: You have to set the value of the DWORT in the registry. You have to open the

Regedit by using Start à Ausführen… à enter regedit à OK. Choose the

following path in the regedit: HKEY_LOCAL_MACHINE à System à

CurrentControlSet à click on Services. On the right side of the window You can

cklick on the name of the DWORd value which is defective (here RxFIFO). Enter

the value 8 with the base hexadecimal. Click Ok an close the regedit. Now You

can start the Tool Set or INPA without an error.

If You have warnings for other DWORDs when startig OBDSetup.exe, You will

have to set the value of the coloum „Expected“ for the wrong value in the registry.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 8 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

1.12 ERROR C1015: Too Many String Variables in Job

Reason: In a job only a maximum of 6 string-variables is acceptable.

Solution: You have to reduce the number of variables.

1.13 Failure: EDIABAS Fehler 159, NET-0009: TIMEOUT

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 9 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

Reason 1: The configuration for the remotehost is false.

Solution 1: Set the corresponding networkname for the remotehost in the configuration file

EDIABAS.INI.

Reason 2: The inface-cable on the OPPS is not correct.

Solution 2: You need a special OPPS-Cable for the connection with the CAN-BUS. (since

type series L6)

Reason 3: In the remotecontrol the OPPS-interface is used by default (since EDIABAS 7.0).

The remotecontrol between two PC’s is not possible with this configuration.

Solution 3: Close all diagnosticapplications and EDIABAS-Processes that are running and

open the file “remote_mit_pc.bat” in the directory C:EDIABASbin.

1.14 Failure: The name of the file or folder can t be changed

Reason: EDIABAS or another component of EDIABAS is still open.

Solution: You have to shut down the diagnosticapplication and EDIABAS. If necessary, the

fileexplorer and the editors which access the EDIABAS-Directory have to close

as well.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 10 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

2 Error Message INPAs

2.1 APLDLL or API32.DLL can’t be found.

When calling INPA under Windows NT, the following error messages appear:

Reason 1: The path C:EDIABASBIN has not been set in the ‘Path’ system variable.

Solution with Windows NT:

Set the system variable: Please log into your system as the administrator with administrator

rights. Use Start à My Computer à Control Panel to call the “System” menu. In the

“Environment” tab, double click the system variable ‘Path’.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 11 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

Go to the end of the field value. There, enter a semicolon and then enter the path

C:EDIABASBIN. Click “Set” and “OK”.

Solution with Windows XP:

Set the system variable: Please log into your system as the administrator with administrator

rights. Use Start à Control Panel to call the “System” menu. Under “Advanced” and the

“Environment” tab, double click the system variable ‘Path’.

Go to the end of the variables field value. There, enter a semicolon and then enter the path

C:EDIABASBIN.

Click “OK”.

Completely restart your computer!!! (Don’t login under a new name or the like.) It should no

longer be a problem to call INPA.

Reason 2: Ediabas is not installed, only INPA is.

Solution 2: Install Ediabas.

When calling INPA under Windows 95, 98, the following error message appears:

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 12 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

Reason: The path C:EDIABASBIN has not been set in the ‘Path’ system variable.

Solution: Set the system variable:

Open the file Autoexec.bat in the directory C: by clicking it with the right mouse key with the

shift key pressed, and then select “Open with”. The best thing is to use the Notepad to

display the file.

Now, at “path”, enter the path c:ediabasbin.

Save the change and close the file.

Completely restart your computer!!! (Don’t login under a new name or the like.)

2.2 Error Message 0020: Incorrect or Missing Driver. The programme will

be aborted!

Conditions:

You have access to smuc0900sg. You are linked to this drive and would like to start an

INPA script.

Reason 1: Missing Ediabas.ini file in C:Winnt.

Reason 2: You are not connected to the controller.

For developers: Simulation is not switched on in the Ediabas.ini file.

Solution: Copy the Ediabas.ini file from C:EdiabasBin to C:Winnt.

2.3 SYS-00002: ECU variation description file not found.

The error occurs when starting an INPA script.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 13 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

Reason 1: The *.prg SGBD is not located in the path C:EdiabasEcu.

Solution 1: Copy the *.prg SGBD into the ECU directory.

Reason 2: The external table T_GRTB.prg doesn’t exist in the directory C:EDIABASECU

or it is obsolete.

Solution 2: Copy the file into the ECU directory or update the external table using the ECCO

Web Client.

2.4 INPA Error: Error at Compiling à Abort!

The following error message appears when starting an INPA script.

Reason 1: An INPA script with the ending IPO was started by the programme INPA.EXE

instead of by the programme INPALOAD.EXE.

Solution 1: Only start INPA scripts that end with IPO with INPALOAD.EXE.

Reason 2: The selected INPA script doesn’t exist in the C:INPASGDAT directory.

Solution 2: Update the INPA scripts using the ECCO Web Client.

Reason 3: INPA Version 5.0.1: The INPA script *.IPO can’t be started with a double-click in

the directory C:INPASGDAT*.IPO.

Solution 3: Update to Version 5.0.2.

Reason 4: INPA Version 5.0.1: The desktop link of an INPA script doesn’t work.

Solution 4: The target path must be expanded to include the INPALOAD path. To do this,

click the desktop link once with the right mouse button and go to ‘Properties’.

Expand the target path to include C:INPABININPALOAD.exe for Windows NT

(see Fig.) and C:EC-AppsINPABININPALOAD.exe for Windows XP.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 14 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

Grund 5: The file startger.ipo of the german installation and the file startus.ipo of the

english installation don’t exist in the directory INPACFGDAT.

Lösung 5: Install INPA once again.

2.5 IFH-0018: Inizialisation Error – INPA doesn’t work but Toolset yet

The error occurs if a SGBD is running by INPA or CASCADE. If the same SGBD is loaded in

the Toolset it will not occure an inizialisation error.

Reason 1: The communications port COM1 doesn’ exist, but COM3 yet. The Toolset is

working without the inizialisation error, because the file OBD.ini exists in the

directory C:Ediabasbin. But the file OBD.ini has to exist in the direcory

C:Windows.

Solution 1: Copy the file OBD.ini in the directory C:Windows or create a new one. (Creation

of OBD.ini q.v. 3.3).

Grund 2: q.v. 3.3

Lösung 2: q.v. 3.3

2.6 IFH-0027: IFH not found à The Programm was aborted!

The error occurs when starting INPA.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 15 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

Reason 1: The setting for the interface in the configuration file Ediabas.ini doesn’t exist.

Solution 1: Please do the settings for the interface e.g.:

Interface = STD:OBD

Reason 2: The setting for the interface in the configuration file Ediabas.ini is

Interface=STD:OMITEC, but the OMITEC driver isn’t installed correctly.

Solution 2: Install the OMITEC driver with the instructions

InstructionforOMITECInstallation.pdf via the GIS server.

Reason 3: The setting for the interface in the configuration file Ediabas.ini is

Interface=OMITEC, but the correct setting is Interface=STD:OMITEC.

Solution 3: Please do the settings for the interface Interface=STD:OMITEC.

Reason 4: The old OMITEC driver wasn’t uninstalled correctly.

Solution 4: Please uninstall the old OMITEC driver with the instructions

InstructionforOMITECInstallation.pdf via the GIS server.

2.7 INPA Error: Opening Inpa – Transmission error returned a_0x2

Reason: During the installation of Ediabas/Inpa, the configuration “Without configuration”

was selected.

Solution: When running the installation programme, select a configuration, e.g. “BMW

Plant 1.1 Munich”.

2.8 INPA Error: Only a white screen appears when you run INPALOAD.EXE.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 16 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

Reason 1: The api.dll or api32.dll file has been manually copied into the WINDOWS

directory with Windows XP and into the WINNT directory with Windows NT.

Solution 1: Delete the file api.dll or alternatively api32.dll from the WINDOWS or alternatively

the WINNT directory. The file may only exist in the directory EDIBASBIN.

Reason 2: You have installed the 32-bit version of INPA (as of Version 5.0.1) and have not

performed an update of the INPA scripts.

Solution 2: Update the INPA scripts using the ECCO Web Client.

2.9 INPA Error: DTM is no longer supported

Reason: This error message appears if INPA.INI has been copied from Version 4.7.7 to

Version 5.x.x.

Solution: Since it can’t be excluded that even more files from the old version have been

mixed with the new ones, the old ones must be deleted, or alternatively

reinstalled (see Chapter 5). Reinstall INPA using the Global Information Service

(GIS) https://gis.bmw.com.

2.10 INPA Error: Bridge16.exe can’t be initialised

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 17 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

Reason 1: A 16-bit INPA script has been started with the 32-bit version of INPA (as

of Version 5.0.1).

Solution 1a): Update the INPA scripts using the ECCO Web Client.

Solution 1b): Convert the INPA script to the standard ‘includes’ for the 32-bit version.

To do this, contact the respective person responsible for INPA at TI-43x

(see smuc0900sgrefReferenzReferenz.inp)

Reason 2: A 16-bit DLL has been found, which means the developer of the INPA

script is using a 16-bit DLL.

Solution 2: The developer of the INPA script must convert the DLL to 32-bit.

2.11 Error when opening the error file à abort:

Reason: This error occurs with Windows XP because the user doesn’t have the correct

rights to change files in the directory C:INPABin.

Solution: The user needs “Power user” rights or the user needs the appropriate write rights

to the “INPA” directory.

2.12 Compiler: File: INPADEUTSCH***.OUT not found!

Reason: The path C:EDIABASBIN has not been set in the ‘Path’ system variable.

Solution: Set the path C:EDIABASBIN in the ‘Path’ system variable. (q.v. chapter 2.1).

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 18 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

3 Tool Set Error Messages

3.1 EDIABAS error 100: SYS-0010: INITIALIZATION ERROR

Reason: This message comes when an SGBD has an automatic concept switch between

multiple diagnostics logs and is not connected to the controller.

Solution: Connect the controller.

3.2 EDIABAS Error 126 (only up to Ediabas V6.4.x)

Reason: This error message appears if you start the Tool Set while an INPA script is

running. This is also true the other way round. The reason for this is that only one

programme can access EDIABAS at a time.

Solution: Therefore, before you start the ToolSet, you must exit INPA!!!

3.3 IFH-0006: Command not accepted and IFH-0018: Initialization Error and

IFH-0038: Interface Command not implemented

Errors IFH-0006 and IFH-0018 occur if any SGBD is loaded in the Tool Set. Error IFH-0038

is generated when loading the utility file into the Tool Set.

Reason 1: The error was caused by another programme that accessed the COM1

interface. This programme could be “HotSync” for Palm or “ActiveSync”

for lpack.

Solution 1: Check the programmes that are started automatically when Windows is

started (see Chapter 4.1).

Reason 2: The COM1 interface is taken by a serial printer.

Solution 2: Uninstall the printer.

Reason 3: The infrared interface is active.

Solution 3: Deactivate the infrared interface.

Reason 4: There is no COM1 interface (COM3 instead, for example)

Solution 4a): Install the COM1 interface.

Solution 4b): Create a file with the name OBD.ini and make the following entry to set

the existing serial interface (COM3, for example):

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 19 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

[OBD]

Port = Com3

The file OBD.ini must be saved in the directory C:WINDOWS for

Windows XP or in directory C:WINNT for Windows NT up to the Ediabas

Package 1.3 and as of Ediabas Package 1.4 in directory

C:EDIABASBIN. The current version of the Ediabas Package can be

seen in the files C:EDIABASversion.txt or C:EDIABASpackage.pdf.

Reason 5: Only for IBM notebooks: The COM1 interface is reserved for the docking

station; the COM3 interface is installed instead.

Solution 5a): see solution 4b:

Solution 5b): Set the COM3 port to COM1: In the device manager (Windows XP:

Select “Start” à “Control Panel” à “System” à “Hardware” and then

select COM3 from the ports under the menu item “Device Manager”.

Then use the right mouse button à “Properties” à “Port Settings” à

“Advanced” to reach the “Advanced Settings for COM3”. Set COM1 in the

COM Port Number. The message that COM1 is already taken can be

ignored in this case.

Reason 6: The old OMITEC driver wasn’t uninstalled correctly.

Solution 6: Please uninstall the old OMITEC driver with the instructions

InstructionforOMITECInstallation.pdf via the GIS server.

3.4 IFH-0006: Command not accepted

This error occurs if a SGBD is loaded in the Tool Set when the OBD connector is being used.

Reason 1: ODB has actually been set as the interface in Ediabas.ini, but the Tool Set uses

the multi-instance with another interface, e.g. K-Line. The setting for the multiinstance

and the interfaces used here is made in the file Tool32.ini in the

directory C:Windows (for Windows XP) or alternatively C:Winnt (for Windows

NT). Then, the entries in Tool32.ini, or alternatively the interface apply and not

the ones in Ediabas.ini. The use of multi-instance in the Tool Set is identified in

the title bar, for example with “Tool32:1”, for single multi-instance.

Solution 2: Enter the interface that is being used in Tool32.ini or disable multi-instance with

the entry “No”.

Reason 2: A SGBD is loaded in the Tool Set when the diagnosis protocol UDS is being

used. For UDS-SGBDs You have to use the interface OMITEC but in the

EDIABAS.ini the setting fort he interface ist „STD:OBD“.

Solution 2: Change the setting for thr interface to „interface = STD:OMITEC“ in the

EDIABAS.ini file. The OMITEC connector has to be stressed by the voltage (blue

blinking). If the connector can’t be stressed by the voltage and You want to load

the SGBD yet, You will use the simulation mode. You can activate the simulation

mode e.g. with the menue „configuration -> EDIABAS“. Notice, if you want to use

the simulation mode, a simulation file for the interface will have to exist in the

simulation path.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 20 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

3.5 IFH-0009: ECU isn’t connected or doesn’t respond

Reason 1: In the Ediabas.ini file, the interface is set to STD:ADS. However, you have

connected an OBD connector.

Solution 1: Modify the interface setting.

Reason 2: The ignition is switched off.

Solution 2: Switch the ignition on.

Reason 3: The device manager has been used to disable the FIFO buffer for COM1.

Solution 3: In the device manager (Windows XP: Enter “Start” à “Control Panel” à

“System” à “Hardware” à “Device Manager” à Ports (COM & LPT)), and select

COM1 from the ports and under the “Port Settings” tab, select “Advanced”. There

must be a check-mark by “Use FIFO buffers” and the highest possible setting

must be selected for the receive buffer.

3.6 SYS-0002: ECU OBJECT FILE NOT FOUND

Reason 1: If the external table T_GRTB.prg doesn’t exist in the directory C:EDIABASECU

the error message will be displayed when You execute the job

IDENT_FUNKTIONAL of a functional SGBD.

Solution 1: You have to download the external table using the ECCO Web Export and copy it

in the directory C:EDIABASECU.

Reason 2: The SGBD, which You want to start doesn’t exist in the directory

C:EDIABASECU or is an old one.

Solution 2: You have to download the SGBD using the ECCO Web Client and copy it in the

directory C:EDIABASECU.

3.7 SYS-0005: Controller description file not found. The programme will be

aborted!

Reason 1: The SGBD is not located in the path C:EdiabasEcu.

Solution 1: Copy the SGBD into the Ecu directory.

Reason 2: This error occurs if the EcuPath in Ediabas.ini (C:EdiabasBin) isn’t set to

C:EDIABASECU.

Solution 2: Set the correct path.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 21 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

3.8 ToolSet Error: Runtime error ’372’

The following error message appears.

Reason: The old version msflxgrd.ocx exists under c:winntsystem32.

Solution: msflxgrd.ocx under c:Ediabasbin must be registered. To do this, select “Start”

à “Run…” and execute regsvr32 :ediabasbinmsflxgrd.ocx in the window and

confirm with “OK“.

The following must be entered for Windows XP: “regsvr32 c:ediabasbin

msflxgrd.ocx“

3.9 Tool Set Error: Run-time error ’5’ – Invalid Procedure Call

Reason: The Tool Set was started twice in a very short period of time.

Solution: Close all Tool Set processes that are running and start the Tool Set again with

only one double-click.

3.10 Tool Set Problem: If an SGBD is opened, then only the hourglass

appears and the SGBD is not loaded.

Reason: An old version Richtx32.ocx exists under c:winntsystem32.

Solution: Richtx32.ocx under c:Ediabasbin must be registered. To do this, select “Start”

à “Run…” and execute “regsvr32 :ediabasbinrichtx32.ocx“ in the window and

confirm with „OK“.

The following must be entered for Windows XP: „regsvr32 c:ediabasbin

richtx32.ocx“

3.11 EDIABAS error 20: IFH-0010: Data transmission to control unit

disturbed

Reason 1: When using the EDIC card, the error message is issued when executing the

IDENT job.

Solution 1: Changes must be made in the file “XEDICC.ini” in the “…EdiabasBin” directory.

There, the parameters set for high-speed must be commented out and the

parameters for low-speed must be enabled:

; highspeed:

;Interface=1;

;Presc=0x01;

;SJW=0x01;

;TSEG1=0x08;

;TSEG2=0x07;

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 22 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

; lowspeed:

Interface=2;

Presc=0x0A;

SJW=0x02;

TSEG1=0x05;

TSEG2=0x02;

Reason 2: A SGBD is loaded in the Tool Set when the diagnosis protocol UDS is being

used. You use the interface OMITEC but the connector isn’t stressed by the

voltage (no blue blinking).

Solution 2: Connect the OMITEC wit the vehicle. The OMITEC connector has to be stressed

by the voltage (blue blinking). If the connector can’t be stressed by the voltage

and You want to load the SGBD yet, You will use the simulation mode. You can

activate the simulation mode e.g. with the menue „configuration -> EDIABAS“.

Notice, if you want to use the simulation mode, a simulation file for the interface

will have to exist in the simulation path.

3.12 EDIABAS Error 134: API-0014: Result not found

The error occurs if a SGBD is loaded in the Tool Set when the diagnosis protocol UDS is

being used and the Job FS_LESEN is being executed.

Reason: You use the setting “read error like INPA”, but the Toolset can’t support the

function yet for UDS-SGBDs.

Solution: Please remove the setting “read error like INPA” in the menue “configuration ->

Toolset”.

3.13 It takes too long to load an SGBD in the Tool Set

Loading motor or transmission SGBDs takes an above average amount of time.

Reason: Large SGBDs often contain many and extensive tables and their information has

to be loaded.

Solution: Under the Configuration menu item in the Tool Set and then Tool Set, the

checkmark by the selection of table information must be removed.

3.14 Black Windows in the Tool Set

After loading a SGBD one or more windows of the Tool Set are black windows.

Reason: The registration of the richtextbox is invalid.

Solution: You have to register the richtextbox. Execute the batch file REGSVR32.BAT in

the directory C:Ediabasbin.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 23 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

4 General Questions

4.1 Installation of EDIABAS and INPA

The Installation of EDIABA, INPA and NFS have to be done webbased via the Global

Information Service (GIS). You can reach the GIS homepage with the following link:

https://gis.bmw.com/.

In the forum „BMW Standard Tools Werk“ You can find the installation data of EDIABAS,

INPA and NFS. The path ist shown below:

BMWStandard ToolsWerk

Standard Tools / Tool InstallationWerk

EDIABAS

INPA

NFS

For acces rights for the GIS forum „BMW Standard Tool Werk“ send an mail to

Referenz@bmw.de stating the name the Q/QX number an the reason. We can give access

rights for this forum only for colleagues from the T departements. Colleagues from other

departments and supplieres can get the installation via the GIS forum „BMW Standard Tools

Entwicklung“. You can apply for access rights using the following link:

https://gis.bmw.com/gis/d/toolsantrag.htm.

Please pay attention to the intallation instructions which You can get in the same directories

of the installation data. After the intallation You have to download the SGBDs, INPA scripts,

Group SGBDs, INPA configuration files and external tables using the ECCO Web Client.

Which data You have to download is described in the following chapter 4.2.

4.2 xBD-Export of SGBDs, Group SGBDs, INPA scripts and INPA

configuration files using the ECCO Web Client

The update of SGBDs, group SGBDs, external tables, INPA scripts and INPA configuration

files can be done webbased using the ECCO Web Client.

You can apply for acces rigths for ECCO at the user service center (Tel. 089-382-55555)

stating Your valid Q/QT/QX number.

You can reach the homepage of the ECCO Web Clients with the following link:

http://www6.muc/ppea. After login You have to select the link xBD Export in the navigation

bar and You can see the search screen. You have the possibility to search for a single file or

search for all files assigned to a certain type serie or search for a several release periods.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 24 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

If You have installed EDIABAS You will need following files:

- SGBD_Revisionen

- GRP_SGBD_Revisionen

- ExterneTabelle_Revisionen

If You have installed INPA You will need following files:

- SGBD_Revisionen

- GRP_SGBD_Revisionen

- ExterneTabelle_Revisionen

- Inpa_Script_Revisionen

In the column „Verfügbare Dateitypen“ You have to select the data types. These column is

very important vor the export of the files, i.e. the data types which are selected will be

exported. Please pay attention on the correct selection.

If You have installed EDIABAS You will select the following data types:

- SGBDprg_english or SGBDprg_deutsch

- SGBDgrp

- EXTABprg_english or EXTABprg_deutsch

If You have installed INPA You will select the following data types in addition to the data

types above:

- INPAipo_english or INPAipo_deutsch

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 25 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

- Select also „Benutzereinst. verwenden“

- Select also „INPA-Konf.-Dateien“

After the download of the necessary files You have to copy the files in the right directories:

EDIABAS data:

1 …EDIABASECU

- SGBDen: SGBDprg_deutsch à alle *.prg-Dateien

- externe Tabellen: EXTABprg_deutsch à T_GRTB.prg, T_PCOD.prg

- Gruppen-SGBDen: SGBDgrp_deutsch à alle *.grp-Dateien

INPA data:

1 …INPASGDAT

- INPA scripts: INPAipo_english à all *.ipo files

1 …INPACFGDAT

- INPA-Konfig-Files: INPA_Konfig_xBD_Download_eng.zip

à all *.ger files or *.eng files

Inpa.ini file

ger = german INPA config, eng = english INPA config

If You have problems with the xBD Export using ECCO Web Client please call the user

service center: Tel. 089-382-55555 or send a mail to ECCO hotline: ecco.hotline@bmw.de.

4.3 How can I find out if the serial interface COM1 has been taken?

There is a way to find out if the serial interface, for example COM1, has been taken, but it is

not possible to find out what programme has taken the interface.

As described in the respective sections of Chapter 3, the programmes that most often take

COM1 are HotSync for the Palm and ActiveSync for the lpack or a Nokia software. In order

to establish whether these programmes are automatically started when you start the

computer, please check your ‘Autostart’ settings. Do this by making sure that these

programmes don’t appear in the following directories:

– C:Documents and SettingsAll UsersStartmenuProgramsAutostart

– C:Documents and SettingsYour QX NumberStartmenuProgramsAutostart

Another way to check the utilisation of COM1 is to look in the system information. The

system information can be run with the DOS command winmsd in an input prompt (Start à

Run… à enter winmsd à OK). Here, it is important that you only run winmsd if the Ediabas

server is closed. Under the path System Summary à Components à Ports à Serial, the

information about the active serial ports COM1, COM2, and so on will be shown if they exist.

The current value can be seen in the element “Busy”. If this value is “No”, then the interface

is free, and if it is “Yes”, then the interface has been taken by a programme. You can’t find

out what programme it is here.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 26 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

4.4 How do I start INPA?

Start Inpa using Inpaload.exe in C:InpaBin or alternatively C:EC-AppsInpaBin or use

Start à All Programs à EDIABAS INPA ELDI NCS NFS à INPA(_.IPO) to start the general

reworking programme. This corresponds to calling Inpaload.exe under

smuc0900sgInpaBin or alternatively C:InpaBin.

4.5 How can I switch between OBD and ADS interfaces?

Prerequisite:

The appropriate driver must be installed for the interface that you want to use. In the

installation guide for INPA (http://smuc0900/TI-430 or http://smuc0900/TI-430 under Subjects à

EDIABAS /INPA à EDIABAS or INPA), you can look up how a driver is installed.

Now, you can change the interface directly in the file Ediabas.ini (C:EDIABASBIN). You

only have to make the appropriate change to the line where the interface is entered.

Interface = STD:OBD, i.e the OBD interface will be used.

Interface = ADS, i.e the ADS interface will be used.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 27 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

For the case that OBD is being used via USB, an additional entry is necessary in OBD.ini.

See C:EDIABASBININI.PDF for this.

4.6 In which directory structure is OBD.ini saved?

If the OBD.ini file exists, then in order to not run the interface via COM1 by default (compare

to 1 i), then the OBD.ini file must be saved in the directory C:WINDOWS for Windows XP

or in directory C:WINNT for Windows NT up to the Ediabas Package 1.3 and as of Ediabas

Package 1.4 in directory C:EDIABASBIN. The current version of the Ediabas Package can

be seen in the files C:EDIABASversion.txt or C:EDIABASpackage.pdf.

4.7 How can I find out what interface I installed with INPA?

To do this, you have 2 possibilities:

- Call Start à All Programs à EDIABAS INPA ELDI NCS NFS à EDIABAS Tool32. In

the configuration menu, select Ediabas. There, you will find the desired information in the

interface line.

- However, you can also check in the Ediabas.ini (C:EDIABASBIN) to see what

interface you have installed. For the OBD interface, you will find the line ‘Interface =

STD:OBD’ and for the ADS Interface the line ’Interface = ADS’.

4.8 How do I find out what EDIABAS package is installed?

The version of the currently installed Ediabas package can be seen in the files

C:EDIABASversion.txt or C:EDIABASpackage.pdf.

4.9 How can I uninstall EDIABAS or INPA?

You uninstall INPA by deleting the Ediabas and Inpa folders under C:.

Reason: No registry entries are made during the installation.

4.10 How can tell if the EDIABAS server is running as a 16-bit or a 32-bit

application?

Under Windows 95 and 98, the EDIABAS server runs as a 16-bit version. The can be

recognised by the yellow E in the task bar.

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 28 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

Under Windows NT4 and XP, the EDIABAS server runs as a 32-bit version. This can be

recognised by the green E in the task bar.

Note:

As of 2003, there is the EDIABAS Version 6.4. This can also run as a 32-bit application

under Windows 95/98 and XP.

4.11 What is the difference between EDIABASbinToolSet.exe and

EDIABAbinTool32.exe?

Tool32.exe is current and when it is started, the Ediabas server will start as a 32-bit

application. ToolSet.exe is an old version and is required under Windows 3.11.

4.12 What is an SGBD and what is its connection to EDIABAS?

The controller description files (SGBD) contain the controller-specific know-how. Each SGBD

contains the order telegram of the respective controller and decodes its reply telegrams. In

the process, the raw data (bytes) is converted into directly useable variables (Data types: int,

long, real, string), i.e the error code is converted into error text.

For each controller variation, there is exactly one variation-specific SGBD.

The SGBDs are loaded and interpreted by the EDIABAS runtime system by an application

programme when the order is issued. The file name of the SGBD (without extension) is the

name with which the application programme addresses a controller variation or controller

group.

4.13 Where are the individual SGBD names and their meanings given in

plain English?

Click the “Show” Version List SGBD button on the ”Dienste Tool” interface. There will be a

list of all SGBDs by name with the current version number, the person responsible at BMW,

and the name of the associated controller. It is only possible to access the version list when

the network is in operation or it can be viewed at smuc0900ReferenzReferenz.sgbd.

4.14 What is a Job?

Jobs are services that EDIABAS provides. They aren’t hard coded in EDIABAS, but are a

main component of each SGBD.

Each job has a fixed name and any number of results. Jobs are independent of each other.

There is no data exchange between jobs.

A job corresponds to a function with one complete order. It usually reads data from a

controller, analyses it and returns results that can be used directly by different applications.

A job normally works with one diagnostics telegram (multiple in exceptional cases).

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 29 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

4.15 What do SGBDs with the name _xxx mean?

SGBDs that begin with “_” (e.g. _LWS5), contain jobs that are only intended for development

(e.g.: writing the ident data). These SGBDs are not used in production or in customer service.

4.16 What is the group file used for?

Among other things, INPA uses group files to select the respective SGBD. The group

identifies the controller and starts the corresponding SGBD. The choice is made using the

diagnostics, and as of E65 using the variation index in addition.

The group files are located in C:EDIABASECU and have the following naming convention:

D_00xx.grp were assigned up to the E65; xx = the controller address; For example:

D_0032.grp = transmission. The name D_??????.grp is assigned after the E65 and is

legible; for example D_KLIMA.grp or D_MOTOR.grp, etc.

Updating the group files as of the E65 has changed since February 2004. The table with the

information about which controller must load which SGBD, depending on the diagnostics and

variation index, was moved from the group file to an external table. At runtime, the swappedout

table C:ECUT_GRTB.prg is used. Therefore, it is now only necessary to update this

table and not D_??????.prg.

Additional Information for SGBD Developers:

In the file STD_GRTB.b2s, the diagnostics and variation indexes of the individual SGBDs

can be seen as well as the group file to which the respective SGBD is assigned. You can

find the file STD_GRTB.b2s on drive smuc0900sg in directory ReferenzEdiabasInclude.

4.17 Diagnostics Index

- a) Who creates it? Reinhold Drexel, TI-430

- b) What is it used for? Identification of the controller

- c) When does it change? When a new SGBD is due

4.18 Variation Index

- a) Who creates it? Data handling team

- b) What is it used for? Identification of the ECU

- c) When does it change? When the SGBD and/or the PABD changes (PABD, if

something in ECU programming changes), e.g. if the

authentication changes or a timing has changed).

4.19 What is the meaning of the file EDIABAS.ini?

Ediabas.ini is the configuration file. Normally, no changes must be made here after the

installation. One reason for a change to Ediabas.ini is, for example, if you want to work with

a simulation file, i.e. there doesn’t have to be a ECU.

The Ediabas.ini can be found in the EdiasbasBin directory.

EcuPath:

The group files (d_*.grp) and SGBDs (*.prg) are found in the path given for EcuPath. In the

developer versions, it also contains *.b2v, *.b2s and *.txt files.

SimulationPath:

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 30 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

The path given in the SimulationPath is where the simulation files are located for groups

(d_*.sim) and for SGBDs (*.sim), which are only relevant to SGBD and INPA developers.

TracePath:

If ApiTrace and/or lfhTrace are activated, then the traces will be stored there with api.trc and

ifh.trc.

TraceSize:

You can set the size of the trace files ApiTrace and IfhTrace. If 1024 is set, then the

maximum size of the file is 1 MB; for 512, it is a maximum of 500 KB.

ApiTrace:

The ApiTrace file is activated by replacing the zero with a number from 1 to 7. The api.trc file

contains the job and result names with their data. If ApiTrace is not needed, this should be

set to zero to increase the performance of EDIABAS. You can find information about the

trace level in the Ediabas documentation.

IfhTrace:

The lfhTrace file is activated by replacing the zero with a number from 1 to 3. The ifh.trc file

only consists of the telegrams that have been sent (INPUT) and received (OUTPUT). If

lfhTrace is not needed, this should be set to zero to increase the performance of EDIABAS.

Simulation:

Simulation is used to check the SGBDs and INPA scripts without being directly connected to

a ECU. This function is activated by changing the zero to 1.

Interface:

You can directly change the interface here. You only have to make the appropriate change

to the line where the interface is entered.

Example:

Interface = STD:OBD, i.e the OBD interface will be used.

Interface = ADS, i.e the ADS interface will be used.

The prerequisite is to have the appropriate driver installed for the interface.

Excerpt form the Ediabas.ini file:

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 31 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

4.20 How is the simulation file connected to the trace file?

There is one simulation file for each ECU. In this file are the ECU’s request and reply

telegrams. This file has the same name as the ECU description file, however it has the

ending “*.SIM” (e.g. DME31.SIM).

There is also a separate simulation file for each interface that is to be simulated. The

filename is made up of the name of the interface with the ending “*.SIM” (e.g. EDIC.SIM).

The setting of the EDIABAS configuration element called Interface will be used as the

interface name. The interface-specific return values are in the interface simulation files.

The trace file records the telegrams that have been sent (INPUT) and received (OUTPUT).

The recording of such traces can be enabled in the Tool Set in the menu bar under

“Configuration” as well as in the Ediabas.ini configuration file.

A simulation file can be automatically created from the ifh.trc trace file by using

trace2sim.exe. This tool is found in smuc0900sgEdiabasSim trace2sim.exe.

4.21 Why have an XBD Generator?

Before the introduction of the SGBD generator, the source code was edited with a text editor

(up to 40,000 lines). For this purpose, it was necessary to learn the special, C-based

programming language BEST/2 (description language for ECU). Manual programming is

known to be very prone to errors (copy & paste), and it is very difficult to implement the

guidelines specified in the diagnostics specification sheet part 5 as the SGBD becomes

larger.

Now, the SGBD Generator is to be used to create an SGBD by means of menu-driven input

of the data, in which the BMW guidelines are kept. This should result in less effort for the

developer, but it definitely requires a certain amount of practice in working with the SGBD

Generator. A major advantage is the automatic integration of standard ‘include’ files,

whereby new standard ‘includes’ can be added without further ado (new sample XML).

4.22 What are the prerequisites for remote access via TCP/IP?

EDIABAS for WIN32 makes it possible to access the diagnostics interfaces and the attached

ECUs that are connected to another PC. The prerequisite for this is a network connection of

locally and remotely controlled PCs via TCP/IP as well as a WIN32 operating system that is

supported by EDIABAS.

Applications and EDIABAS run on the local PC and the interface handler (IFH) as well as the

IFH-Server run on the PC to be remotely controlled. Before accessing the remotely

controlled PC, the IFH server IFHSRV32.EXE must be started. The remote control is

activated, or alternatively controlled using the EDIABAS configuration file EDIABAS.INI. The

EDIABAS configuration must be performed manually on both PCs.

The EDIABAS configurations TracePath and SimulationPath are not transferred from the

local PC to the remotely controlled PC, rather the respective configurations of the

EDIABAS.INI file that is on the remotely controlled PC is used.

The network protocol TCP (NetworkProtocol entry) as well as a freely selectable port

number must be given on both PCs. The port number must be identical on both PC and

must not collide with other TCP applications (1000 < port number < 30000).

Frequently Asked Questions

BMW Group about

EDIABAS, INPA and the Tool Set Page 32 of 32

TI-430 Andreas Schandl Release date: 29.09.2006

4.23 What is the VC Tool and when is it used?

VC Tool (version check) can be used to check the versions of the files that are created

during the installation of EDIABAS. When it runs, the tool compares the files specified in the

files BMW_bin.pid, BMW_hw.pid and BMW_rest.pid with regard to their creation data and

creation time. That way, changes made incorrectly in the EDIABAS files can be detected and

corrected.

After running, the VC Tool creates a text file called VC.log in which the comparison is given

with the specific results. This file is stored in the directory where the VC Tool is found

(C:EDIABAS).

4.24 What is the KVP Editor?

KVP stands for continuous improvement process. The KVP Editor can be called when using

the INPA Tool. This is mainly used in reworking and in the plant. Here, the user has the

possibility to enter his name and telephone number and then enter an error description and

improvement request and then to send the form directly to the person responsible at BMW.

(Visited 928 times, 1 visits today)

In this article I will share solutions of BMW INPA Errors,belows list 12 errors of BMW INPA when installing BMW INPA Software.Hope it is helpful!

Error Message 0020: Incorrect or Missing Driver. The programme will be aborted!

Conditions:

You have access to smuc0900sg . You are linked to this drive and would like to start an INPA script.

Reason 1: Missing Ediabas.ini file in C:Winnt.

Reason 2: You are not connected to the controller.

For developers: Simulation is not switched on in the Ediabas.ini file.

Solution: Copy the Ediabas.ini file from C:EdiabasBin to C:Winnt.

SYS-00002: ECU variation description file not found.

The error occurs when starting an INPA script.

Reason 1: The *.prg SGBD is not located in the path C:EdiabasEcu.

Solution 1: Copy the *.prg SGBD into the ECU directory.

Reason 2: The external table T_GRTB.prg doesn’t exist in the directory C:EDIABASECU

or it is obsolete.

Solution 2: Copy the file into the ECU directory or update the external table using the ECCO

Web Client.

INPA Error: Error at Compiling Abort!

The following error message appears when starting an INPA script.

Reason 1: An INPA script with the ending IPO was started by the programme INPA.EXE

instead of by the programme INPALOAD.EXE.

Solution 1: Only start INPA scripts that end with IPO with INPALOAD.EXE.

Reason 2: The selected INPA script doesn’t exist in the C:INPASGDAT directory.

Solution 2: Update the INPA scripts using the ECCO Web Client.

Reason 3: INPA Version 5.0.1: The INPA script *.IPO can’t be started with a double-click in

the directory C:INPASGDAT*.IPO.

Solution 3: Update to Version 5.0.2.

Reason 4: INPA Version 5.0.1: The desktop link of an INPA script doesn’t work.