Тема: Parking lights (check left) что за. ?

Parking lights (check left) что за. ?

Вчера менял свечи. Скинул минус перед операцией на всякий пожарный (если важно).

Завожу машину. Вижу на БК:

Изображена машина с выделенной левой передней фарой. С сообщением Parking lights (check left) которое гаснет через несколько секунд.

Ну погасло и погасло. Утром та же фигня. Доехал до парковки заглушил двигатель, и через несколько секунд завел — сообщение не повторилось — все было как обычно.

Кто-нибудь сталкивался?

Свет горит вроде нормально, посмотрел включенные габариты и ближний. Никаких глюков замечено не было.

габарит левый гаснет. Может контакт плохой, вот тебе БК и пишет

хз. вроде горит. может и в самом деле контакт плавает. просто странное совпадение.

maximk1974

а ты возьми и проверь! именно габарит! левый!

Добавлено спустя 16 секунд:

maximk1974

у тебя случаем не диоды?

maximk1974

а ты возьми и проверь! именно габарит! левый!

Добавлено спустя 16 секунд:

maximk1974

у тебя случаем не диоды?

Утром проверял — все было ок (я же написал выше).

Диоды или нет — не в курсе, astra 2007 хетч с роботизированной коробкой. Не знаю что там штатно установлено, менял пока только лампы ближнего света.

Вечером посмотрю повнимательнее.

Добавлено спустя 6 минут 25 секунд:

О! вроде теперь все ясно. У приятеля такая же хрень была. Лампа горит а БК пишет такую ошибку. Лампа может гореть, но на последнем издыхании. Сопротивление меняется и это дает БК инф-цию, что лампу пора менять.

BTW там не диод, обычная лампочка. Сегодня заменю, если куплю.

Источник

Parking light опель астра h что означает

Выключаем зажигание (можно извлечь ключ), включаем «поворотник» в ту сторону, которую нужно обозначить. Габаритные огни с необходимой стороны а/м включены.

2. Дорога к дому.

Выключаем зажигание, извлекаем ключ, открываем водительскую дверь, мигаем дальним светом фар. У нас есть 30 секунд на закрытие машины и перемещение по освещенной дороге.

3. Частота работы «дворников».

Включаем «дворники» на один проход (переключатель в низ), выдерживаем паузу которая необходима для работы щеток стеклоочистителя (интервал от 2 до 15 сек.) и включаем переключатель в первое положение (прерывистый режим, на один «шаг» в верх).

Еще одна интересная опция работы «дворников» Opel — если включены щетки стеклоочистителя лобового стекла, то при включении задней передачи автоматически включается «дворник» заднего стекла.

Для установки «дворников» в вертикальное положение (для удобства при замене или в зимний период) выключаем зажигание (ключ не достаём) и моментально нажимаем переключатель дворников в низ (один проход), удерживаем в течении 3-5 секунд. Отпускаем переключатель, когда дворники достигли желаемого положения на лобовом стекле.

4. Коды ошибок . (тут расшифровка ошибок)

Если на панели приборов загорелась машинка с ключиком, значит блок управления зарегистрировал неисправность в работе автомашины. Считать код ошибки можно следующим способом;

— одновременно нажимаем на педаль тормоза и газа, не отпускаем;

— вставляем ключ в замок зажигания и поворачиваем до включения контрольных ламп на панели приборов, но не заводим;

— ждем появления надписи ECN на месте высвечивания пробега авто.

|

| Код ошибки |

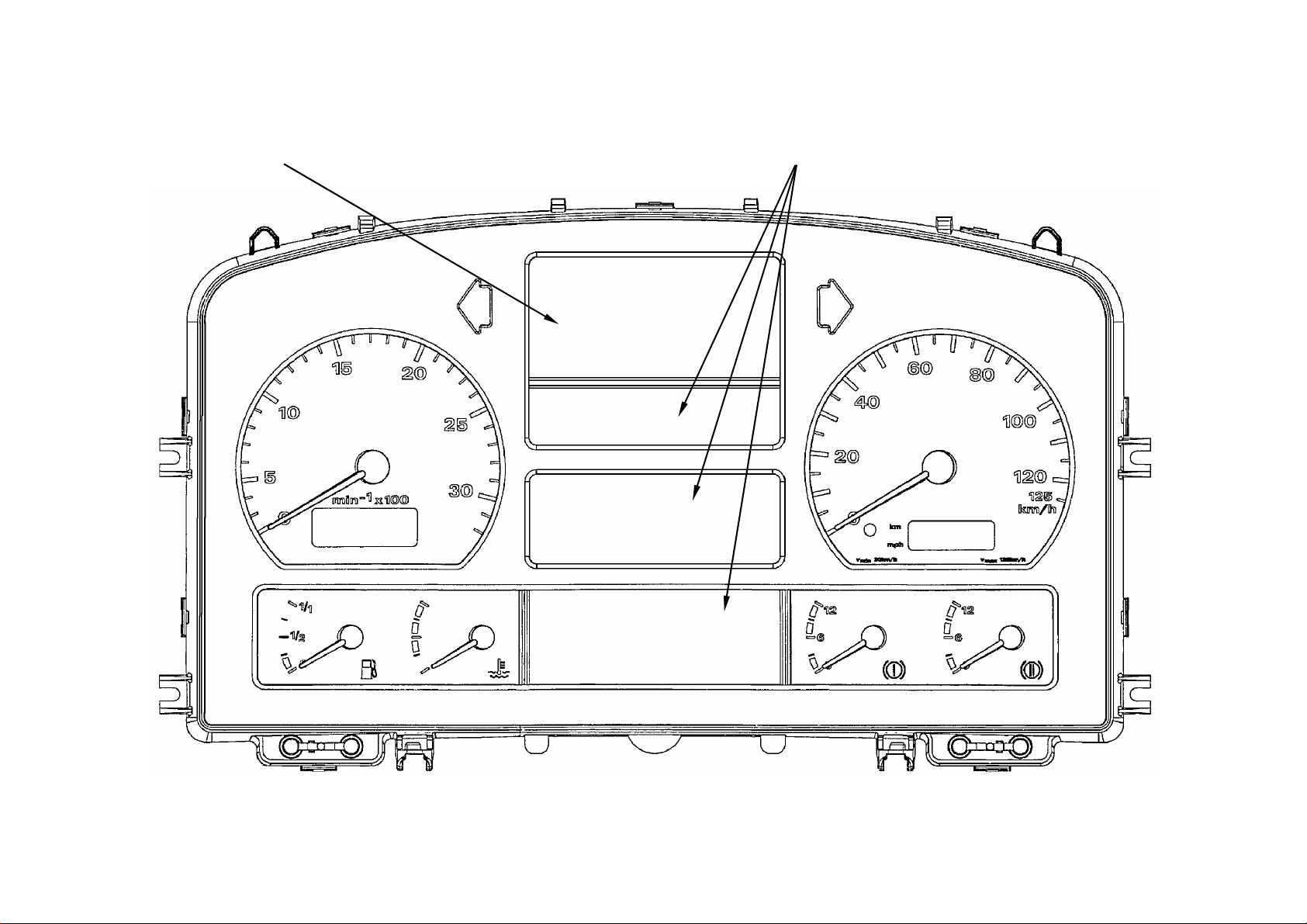

Первые четыре цифры отражают код ошибки, последние две — значение ошибки. Если ошибки отсутствуют, то высвечиваются нули (см. фото).

5. InSP или оставшийся пробег до ТО.

Для своевременного проведения технического обслуживания автомобиля предусмотрено графическое оповещение приближающегося техосмотра. Нарушение сроков прохождения ТО влекут за собой нестабильность работы узлов и агрегатов автомашины. Если у Вас на панели приборов высветилась надпись InSP, значит настало время свериться с сервисным буклетом, где указана периодичность обслуживания.

Для сброса показаний счетчика необходимо сделать следующее:

— включить зажигание (не заводить двигатель);

— выключить зажигание;

— нажать и удерживать кнопку сброса суточного пробега (на дисплее высветится остаток км до ТО);

— не отпуская кнопку, выжмите педаль тормоза и удерживайте;

— включите зажигание (обнуление показаний, мигание надписи InSP);

— удерживайте кнопку и педаль тормоза пока не пропадет мигающая надпись;

— отпускаем педаль тормоза и кнопку.

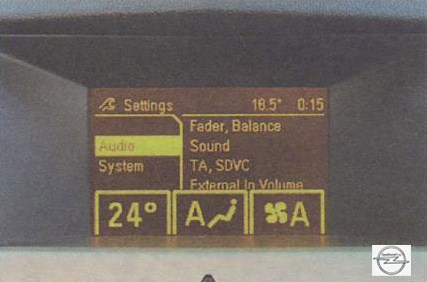

6. Тест-режим BC

Для включения тестового режима BC необходимо сделать следующее:

— включите магнитолу (радиоприёмник);

— нажмите кнопку «Settings» и удерживайте ее до звукового сигнала;

— нажатием кнопки «BC» листаем экраны с данными.

|

| Testmode: Heater |

|

| Testmode: Dimming |

Input; Chart; LEDs — значения изменяются при включении габаритов и регулировке яркости подсветки.

Opel Astra H (Family) / Руководство

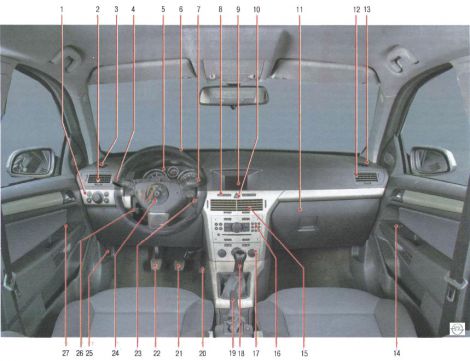

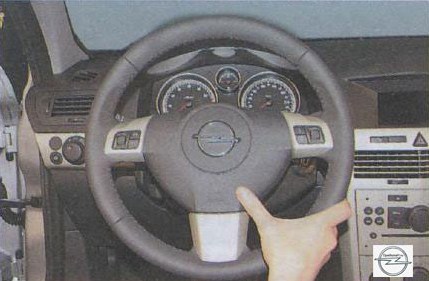

Расположение органов управления автомобилем Opel Astra показано на рис. 1. Для удобства пользования на ручки, кнопки и контрольно-измерительные приборы, расположенные на панели приборов и других дополнительных панелях управления, нанесены символы функционального назначения.

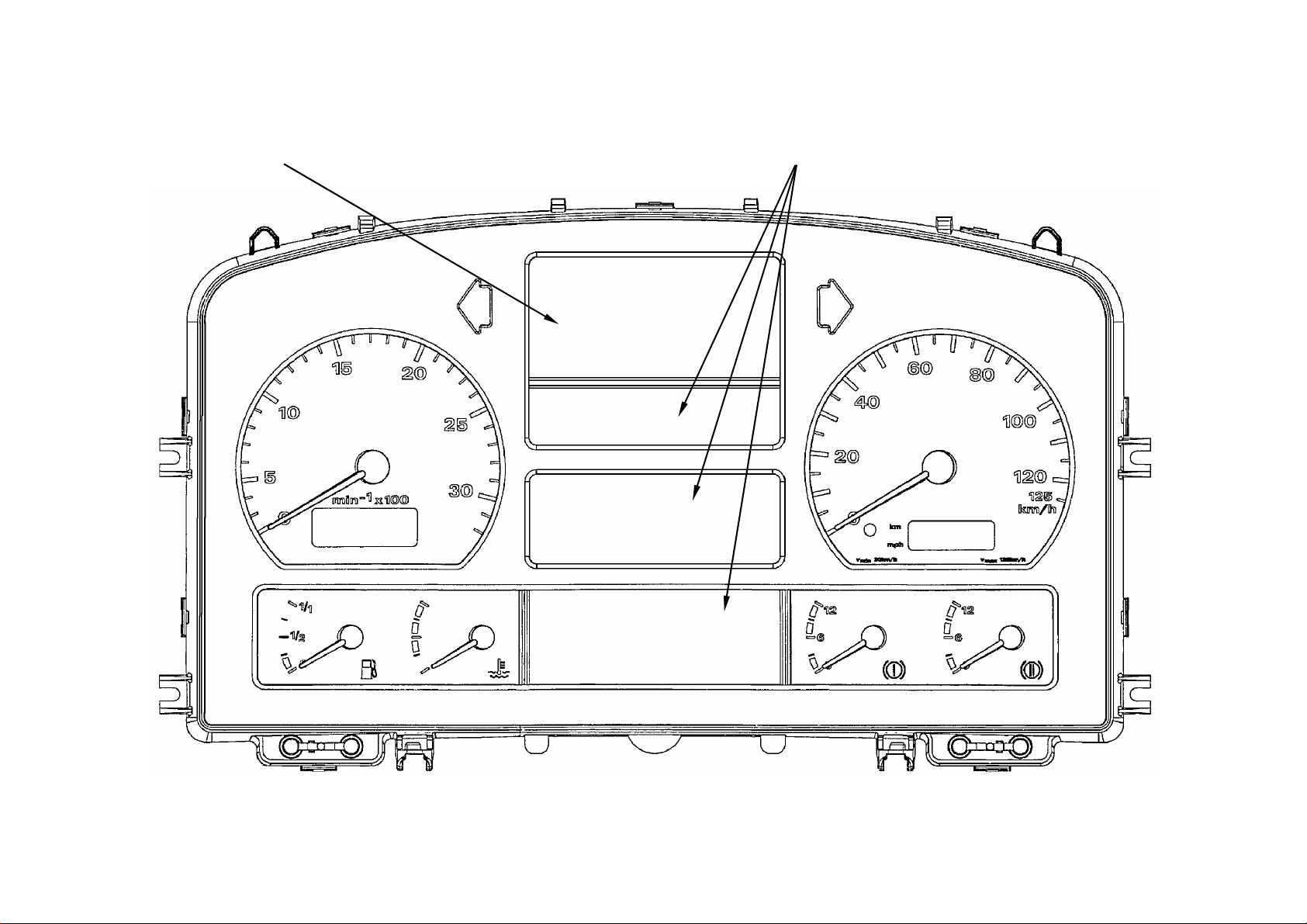

Рис. 1. Панель приборов и органы управления

На панели приборов расположены следующие органы управления и контрольно-измерительные приборы (см. рис. 1).

1 — блок управления наружным освещением, яркостью подсветки комбинации приборов, задними противотуманными фонарями и электрокорректором света фар.

Поворотом рукоятки переключателя наружного освещения включают габаритный, ближний или дальний свет. Рукоятка может занимать следующие положения:

— все выключено;

— включен габаритный свет;

— включен ближний/дальний свет.

Нажатием на левую нижнюю кнопку блока включают свет в задних противотуманных фонарях. При повторном нажатии на кнопку противотуманные фонари выключаются. Аналогично включают и выключают противотуманные фары (если они установлены), нажав на левую верхнюю кнопку блока (на фото вместо кнопки установлена заглушка).

Нажатием на правую нижнюю рукоятку блока разблокируют регулятор электрокорректора света фар (при этом рукоятка выдвигается из блока).

Поворотом рукоятки регулятора в зависимости от загрузки автомобиля изменяют угол наклона пучка света фар таким образом, чтобы исключить ослепление водителей встречного транспорта. Совмещая метку на рукоятке регулятора и цифры на шкале, выбирают соответствующую регулировку положения фар при следующих вариантах загрузки автомобиля:

0 — один водитель или водитель и пассажир на переднем сиденье;

2 — все места заняты и груз в багажнике;

3 — один водитель и груз в багажнике.

По окончании регулировки заблокируйте регулятор, утопив его рукоятку в блок.

Нажатием на правую верхнюю рукоятку блока разблокируют регулятор яркости подсветки комбинации приборов и информационного дисплея (при этом рукоятка выдвигается из блока).

Для увеличения яркости подсветки поверните рукоятку в направлении знака «+» и удерживайте ее в этом положении до достижения требуемой яркости (яркость подсветки изменяется автоматически). Аналогично уменьшайте яркость подсветки, повернув рукоятку регулятора в направлении знака «-». По окончании регулировки заблокируйте регулятор, утопив его рукоятку в блок.

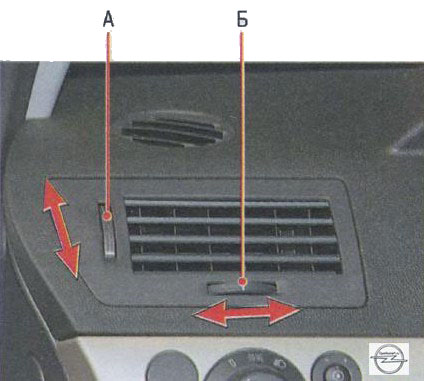

2 и 12 — боковые сопла системы вентиляции и отопления салона. Поворотом рукоятки А изменяют интенсивность потока воздуха, причем в крайнем нижнем положении рукоятки поток воздуха максимален, а в крайнем верхнем — перекрыт (на рукоятке виден символ «O»). Рукояткой Б регулируют направление потока воздуха.

3 и 13 — сопла обдува стекол дверей.

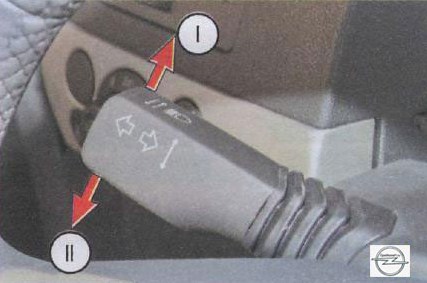

4 — рычаг переключателя наружного освещения и указателей поворота. Рычаг переключателя может занимать следующие положения:

I — включены указатели правого поворота (фиксированное положение);

II — включены указатели левого поворота (фиксированное положение);

При перемещении рычага в положение «I» или «II» в комбинации приборов загорается мигающим светом контрольная лампа 10 или 13 (см. рис. 2). При возврате рулевого колеса в положение прямолинейного движения рычаг автоматически устанавливается в исходное положение. При смене полосы движения для включения указателя поворота достаточно нажать на рычаг в направлении положения «I» или «II» только до момента ощутимого сопротивления, не фиксируя рычаг, и отпустить. Указатели поворота в этом случае мигнут три раза.

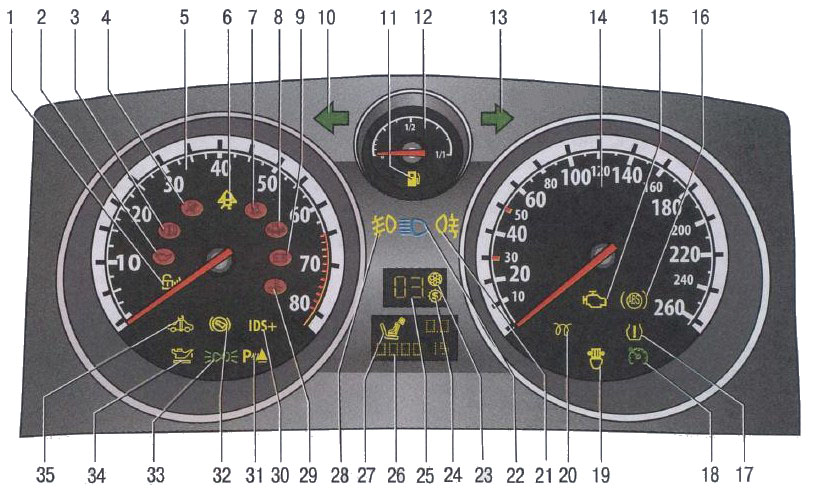

Рис. 2. Комбинация приборов

Для переключения между дальним и ближним светом фар (рукоятка переключателя наружного освещения в блоке управления 1 на рис. 1 должна находиться в положении

) передвиньте рычаг переключателя к рулю на две позиции и отпустите.

При включении дальнего света в комбинации приборов загорается контрольная лампа 22 (см. рис. 2).

Для сигнализации дальним светом фар передвиньте рычаг переключателя на одну позицию к рулю (рукоятка переключателя, наружного освещения в блоке управления 1 (см. рис. 1) наружного освещения должна находиться в положении

) и отпустите.

При включении дальнего света в комбинации приборов также загорается контрольная лампа 22 (см. рис. 2).

По заказу может быть введена функция «освещение дороги к дому». Если при выключенном зажигании и открытой двери водителя передвинуть рычаг переключателя на одну позицию к рулевому колесу, а затем отпустить, то активируется функция задержки выключения фар: включится ближний свет фар и свет фонарей света заднего хода, который выключится только через 30 мин после закрытия последней двери. Для того чтобы выключить фары, переместите рычаг переключателя на одну позицию к рулевому колесу и отпустите еще раз.

Если выключатель (замок) зажигания находится в положении «О» или «I», при включенном наружном освещении в момент открытия двери водителя включится зуммер, напоминающий о необходимости выключить освещение.

По заказу может быть введена функция стояночного света. При парковке автомобиля можно включить передний и задний габаритные огни с одной стороны автомобиля, для чего при выключенном зажигании и рукоятке переключателя наружного освещения в блоке управления 1 (см. рис. 1) наружного освещения в положении «0» поверните рычаг переключателя наружного освещения и указателей поворота в нужную сторону. При этом включится зуммер и одновременно загорятся контрольные лампы 10 и 13 (см. рис. 2) в комбинации приборов.

5 — комбинация приборов (см. Комбинация приборов).

По заказу в спицы рулевого колеса могут быть установлены пульты дистанционного управления развлекательной системой и аудиосистемой.

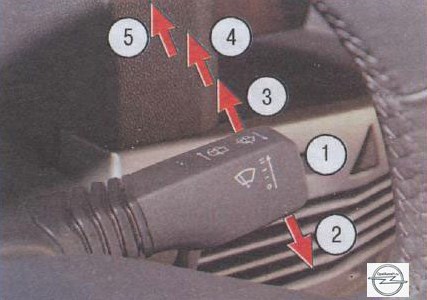

7 — рычаг переключателя стеклоочистителя и омывателя ветрового окна и окна двери задка (на автомобилях с кузовами универсал и хэтчбек).

включает электрические цепи при включенном зажигании и может быть установлен в следующие положения:

1 — стеклоочиститель выключен;

2 — щетки стеклоочистителя совершат один цикл;

3 — включен прерывистый режим работы стеклоочистителя. Для регулировки времени задержки между циклами (если эта опция установлена) нажмите на рычаг вниз из положения 1, выждите желаемый промежуток времени и установите рычаг в положение 3;

В зависимости от комплектации вместо стеклоочистителя с прерывистым режимом может быть установлен стеклоочиститель с автоматическим режимом работы. В этом случае при установке рычага переключателя в положение 3 активируется автоматический режим.

4 — включена первая (низкая) скорость стеклоочистителя;

5 _ включена вторая (высокая) скорость стеклоочистителя.

При перемещении рычага к рулевому колесу на одну позицию включатся очистители и омыватели ветрового стекла и стекол фар (если установлены).

При перемещении рычага от рулевого колеса на одну позицию включатся очиститель и омыватель стекла двери задка. При удерживании рычага в этом положении включится омыватель стекла двери задка на все время удерживания рычага.

Стеклоочиститель окна двери задка включится автоматически (зависит от комплектации) при включении передачи заднего хода, если рычаг стеклоочистителя находится в положении «2», «3» или «4».

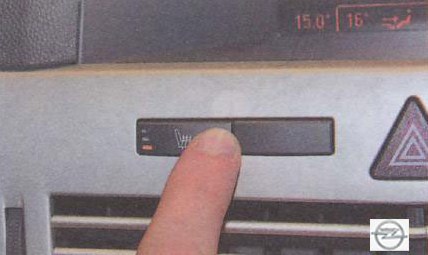

8 — выключатель обогрева сиденья водителя.

В зависимости от требуемой степени обогрева сиденья нажмите на кнопку выключателя один или несколько раз. При каждом нажатии степень обогрева увеличивается и в кнопке загорается еще один сигнализатор. Для выключения обогрева нажимайте на кнопку несколько раз до тех пор, пока не погаснут все сигнализаторы.

Аналогичный выключатель установлен в облицовочной накладке панели приборов справа симметрично продольной оси автомобиля Опель Астра. Он служит для включения обогрева сиденья переднего пассажира и функционирует по тому же алгоритму, что и выключатель обогрева сиденья водителя. По заказу в общих блоках с выключателями обогрева сидений водителя и переднего пассажира могут быть установлены выключатели системы контроля падения давления в шинах, парктроника, спортивного режима, центрального замка.

9 — центральный информационный дисплей.

На дисплей выводится время, дата и наружная температура. В зависимости от комплектации автомобиля дисплей служит для получения информации от бортового компьютера (если он установлен), для визуального контроля при управлении аудиосистемой и системой отопления (кондиционирования) салона, а также развлекательной системой (если перечисленные системы установлены на автомобиле).

10 — выключатель аварийной сигнализации.

При нажатии на клавишу выключателя загораются мигающим светом все указатели поворота и соответствующие им контрольные лампы, установленные в комбинации приборов. При повторном нажатии на клавишу сигнализация отключается.

Аварийная сигнализация работает при любом положении ключа в выключателе (замке) зажигания.

Служит для хранения мелких вещей и открывается при нажатии на ручку замка вверх. Подробно дополнительные функции вещевого ящика описаны в подразделе Вещевые ящики салона и электрическая розетка.

14 и 27 — пульты управления электростеклоподъемниками и наружными зеркалами заднего вида. В соответствующих подразделах подробно описаны приемы управления стеклоподъемниками (см. Боковые двери) и зеркалами (см. Зеркала заднего вида).

15 — центральные сопла системы вентиляции и отопления салона.

Алгоритм управления потоком и интенсивностью воздуха через центральные сопла такой же, что и для боковых сопел 2 и 12.

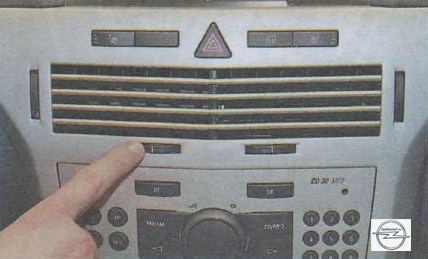

16 — панель управления аудиосистемой.

Приемы управления аудиосистемой подробно описаны в разд. «Электрооборудование» (см. Автомобильная аудиосистема).

Помимо органов управления аудиосистемой на панели 16 в зависимости от комплектации автомобиля могут быть установлены органы управления информационно-развлекательной системой и бортовым компьютером.

17 — блок управления системой отопления (кондиционирования) и вентиляции салона.

18 — рычаг управления коробкой передач.

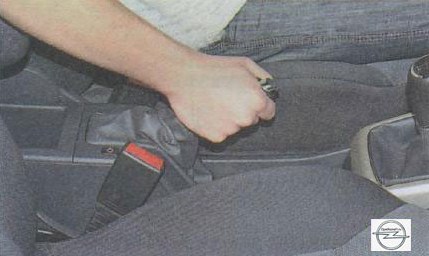

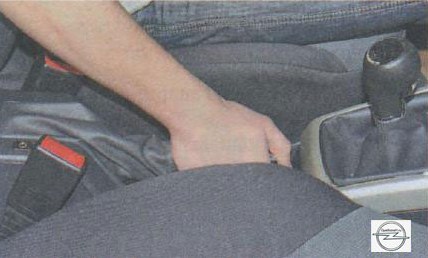

19 — рычаг стояночного тормоза.

Для того чтобы затормозить автомобиль Opel Astra стояночным тормозом, поднимите рычаг до упора вверх — в комбинации приборов загорится красным светом сигнальная лампа 3 (см. рис. 2).

Для того чтобы растормозить автомобиль, потяните рычаг немного вверх, нажмите на кнопку в торце рукоятки рычага.

. и опустите рычаг до упора вниз контрольная лампа должна погаснуть.

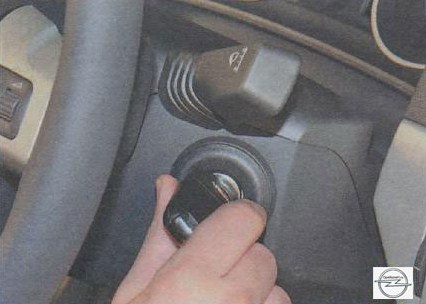

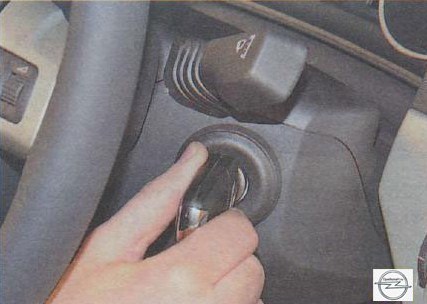

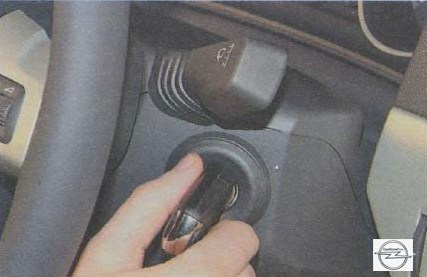

23 — выключатель (замок) зажигания, объединенный с противоугонным устройством, расположен с правой стороны рулевой колонки.

Ключ в замке может занимать одно из четырех положений:

— 0 (блокировка) _ зажигание выключено, при вынутом ключе включено противоугонное устройство.

Для гарантированного блокирования вала рулевого управления поверните рулевое колесо вправо или влево до щелчка.

Для выключения противоугонного устройства вставьте ключ в выключатель зажигания и, слегка поворачивая рулевое колесо вправо-влево, поверните ключ в положение «I»;

Не выключайте зажигание и не вынимайте ключ из замка во время движения: рулевое управление будет заблокировано и автомобиль станет неуправляемым.

— I (дополнительное оборудование) — зажигание выключено; ключ не вынимается, рулевое управление разблокировано. Включены цепи питания звукового сигнала, наружного освещения, сигнализации дальним светом фар, радиооборудования, прикуривателя и пр.;

— II (включено) — зажигание включено, ключ не вынимается, рулевое управление разблокировано. Включены зажигание, приборы и все электрические цепи;

— III (стартер) — включены зажигание и стартер, ключ не вынимается, рулевое управление разблокировано. Это положение ключа нефиксированное, при отпускании ключ под действием усилия пружины возвращается в положение «II».

24 — выключатель звукового сигнала.

Для того чтобы включить звуковой сигнал, нажмите на любое место центральной накладки рулевого колеса.

Приборная панель Opel Astra H: описание значков

Стандартная панель приборов Опель Астра Аш представляет собой информативный элемент конструкции авто, обладающий полным списком индикаторов. На моделях 2007-2008 годов, приборка не отличается и считается самой удобной. Информационные значки интуитивно понятны и легко читаются.

Некоторые автолюбители жалуются на недостаточную освещенность панели. Это заставляет их устанавливать более мощную подсветку и менять подложку.

Описание обозначений значков приборки

Все лампочки и индикаторы приборки можно разделить на три группы.

- Информационные. Символы загораются зеленым светом и не указывают на ошибки – это только для уведомления водителя.

- Предупреждающие. Индикаторы желтого цвета требуют обратить внимание пользователя на состояние автомобиля.

- Сигналы ошибок. Лампы красного цвета предупреждают о том, что в машине присутствует критическая поломка.

Расшифровка индикаторов, указанных на фото приведена ниже.

Горит ключик

Когда на приборке загорается индикатор типа машинка с ключиком – это может указывать на проблемы в синхронизации работы двигателя и коробки. Также могут быть проблемы с агрегатами по отдельности. В этом случае потребуется приехать на СТО и выполнить компьютерную диагностику для точного определения поломки.

Желтая масленка

Загорается при падении уровня масла в моторе. При преодолении ухабов или движении под уклоном, индикатор может мигать – это не страшно и случается постоянно. Проблемой считается, когда индикатор горит постоянно.

Обычно достаточно долить масло в мотор и (при наличии) устранить протечки.

Как сделать пересвет приборной панели

Пользователи делают только по причине неудовлетворенности цветом подсветки. Для этого потребуется полностью разобрать панель и перепаять диоды на те, которые хочется.

Главным параметром при выполнении работ считается точный подбор модели диода и твердая рука мастера. На схеме все элементы маленькие, без опыта выполнения подобных работ можно сильно накосячить.

Тест приборки

Тестирование панели выполняется через специальное ПО. Для этого на компьютер скачивается диагностическая программа и подключается к машине. Методика помогает обнаружить ошибки и устранить их.

Для выполнения операции рекомендуется обратиться к специалисту – без должного опыта легко запороть заводское ПО.

Не работает щиток приборов

Если приборка не горит и отказывается работать – это является последствием потери питания. Устранить проблему можно следующим образом.

- Проверить соответствующий предохранитель.

- Продиагностировать проводку и клеммы питания.

- Выполнить сброс бортового компьютера.

Если ничего не помогло – рекомендуется выполнить замену приборки.

Моргает приборка Астра Н

Когда панель моргает – дело кроется в неправильной работе диода. Причин может быть две.

- Перегорает диод.

- Плохой контакт на клемме питания подсветки.

В первом случае потребуется перепайка элемента. Второй вариант решается чисткой клемм.

Как снять панель и щиток приборов Astra H

Снятие торпеды своими руками происходит так.

- Отключить питание от аккумулятора.

- Крестовой отверткой откручивается кожух рулевой колонки.

- Откручивается нижняя часть консоли.

- Теперь есть доступ к крепежным винтам самой приборки. Их следует выкрутить.

- Последний этап – отключить клеммы питания панели и ее можно полностью снять с машины.

Разборка полностью завершена. Собирать панель следует в обратной последовательности.

Панель Astra информативна и эргономична. Приборка легко читается имеет приятный внешний вид и не капризничает во время эксплуатации.

Специализация: Закончил государственный автомобильный университет, проработал 20 лет на ГАЗ-56, сейчас езжу на жигулях.

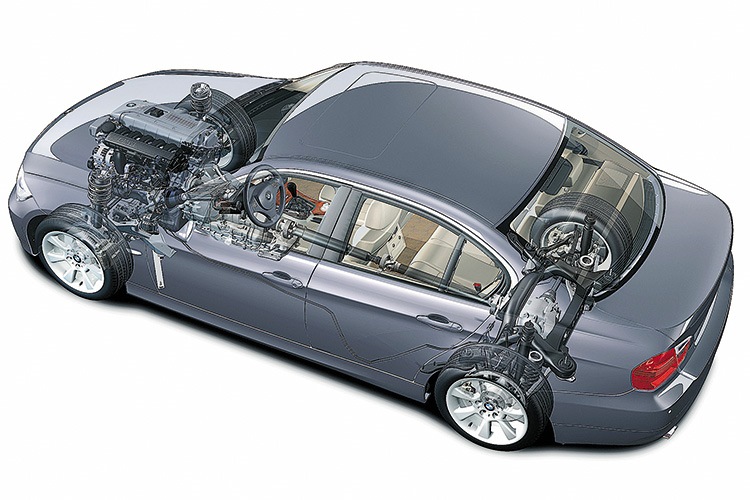

С оглядкой на коробку. Что стоит учитывать при выборе подержанного Opel Astra H

О дизайне не спорят. А в случае с Opel Astra Н это еще более справедливо по отношению к интерьеру. Но мы же про подержанный автомобиль говорим, а там куда важнее ресурс, надежность, ремонтопригодность. Как обстоят дела с этим?

- В странах Западной Европы Astra H продавали в 2004-2010 годах, однако на некоторых рынках модель присутствовала вплоть до 2014-го. Выпускали ее в Германии, Польше и России.

- В данном поколении Astra была представлена с большим выбором кузовов: 5-дверный хэтчбек, 3-дверный хэтчбек GTC, седан, универсал Caravan и кабриолет TwinTop.

- На базе Astra H создано второе поколение компактвэна Zafira В (2005-2009 г.в.). Учитывая единую агрегатную базу и техническое сходство обеих моделей, практически все сказанное по отношению к Astra H по части эксплуатационных особенностей, надежности и ремонтопригодности будет справедливо и для Zafira B.

- В 2004 году по результатам испытаний по методике EuroNCAP хэтчбек Astra H заработал максимальные пять звезд (34 балла) за защиту водителя и взрослого пассажира. Защита пассажира- ребенка была оценена в четыре звезды (39 баллов). И лишь к пешеходам немецкий автомобиль оказался не очень дружелюбен, за что получил всего одну звезду (3 балла).

Рынок

Типичный средний ценник на Astra H – это порядка 4500-5500$ за автомобили 2007-2010 г.в. За машины первых лет выпуска просят порядка 3000$, а самые дорогие предложения – преимущественно универсалы младше 10 лет – стоят в районе 7000-7500$.

Бензиновые и дизельные версии одинаково популярны, а вот на долю машин с «автоматом» приходится менее трети предложений. Каждая третья Astra H – с кузовом универсал, чуть менее популярен 5-дверный хэтчбек, но еще меньше предложений по 3-дверным GTC и седанам, а кабриолет и вовсе эксклюзив.

Кузов, салон, электрика

Уже предшествующее поколение Astra G показало, что шутки о гниющих Opel можно забыть. Поколение H также демонстрирует высокую стойкость кузова к коррозии, так что ржавые экземпляры – это обычно примеры некачественного восстановительного ремонта после ДТП. Но ЛКП достаточно тонкое и нежное, так что товарный вид во многом зависит от аккуратности и дотошности владельца. В любом случае наиболее уязвимые для механических повреждений места (кромки капота, крыши, дверей и крышки багажника, колесные арки и пороги) следует осматривать, а обнаруживаемые сколы оперативно ремонтировать.

Главная претензия к салону – слишком уж казенный у него интерьер: для служебного автомобиля, может, это и неплохо, но для семейного не хватает «уюта». Зато качество отделочных материалов неплохое, они долго сохраняют свой первоначальный вид, особенно если не было интенсивной эксплуатации служебного или прокатного автомобиля.

Что касается надежности оборудования, то, как и на других моделях Opel тех лет, проблемы с электрикой возникают из-за отказов CIM-модуля, а еще на возрастных машинах довольно часто случаются проблемы с климат-контролем, причем не с самим кондиционером (здесь все как у всех: с возрастом возможны утечки хладагента, за этим надо просто следить, восстанавливать герметичность, заменяя отказавшие детали), а именно с управлением – работой клавиш и регуляторов, электроприводом заслонок и т.д., так что работу системы перед покупкой лучше проверить, причем именно в процессе смены режимов.

Бензиновые двигатели

Если говорим про бензиновые версии, то подавляющее большинство машин, представленных на рынке, оснащено атмосферными двигателями. Первые несколько лет на модель устанавливали старые моторы Z16XE/XEP (105 л.с.) и Z18XE (125 л.с.), затем перешли на более современные Z16XER (115 л.с.) и Z18XER (140 л.с.): чугунный блок и распределенный впрыск остались, а вот гидрокомпенсаторы исчезли. «Младший» двигатель 1.4 (90 л.с.) не обладает большой мощностью, зато радует экономичностью. В отличие от других моторов привод ГРМ здесь цепной (реальный ресурс цепи порядка 200 тыс. км).

Несмотря на различия, с точки зрения долговечности и надежности все эти двигатели примерно сопоставимы. «Железо» ходит не менее 300 тыс. км., а основные вопросы касаются навесного оборудования и вспомогательных систем.

Двигатели 1.4 и 1.6 оснащены системой Twinport – подробно о ее особенностях и недостатках мы уже рассказывали, здесь же повторим основные моменты. Суть технологии заключается в перекрывании одного из двух каналов, приходящихся на каждый цилиндр, в режиме частичной нагрузки – это позволяет оптимизировать процесс смесеобразования и положительно сказывается на отзывчивости двигателя и его экономичности. Со временем система начинает «сбоить»: возникают люфты в механизме привода заслонок, иногда они подвисают в открытом или закрытом положении, часто из-за накопленных отложений во впуске. Они же являются причиной проблем с EGR.

Новые версии моторов 1.6 и 1.8 получили фазовращатели, которые со временем также могут стать причиной обращения на сервис. Еще один источник проблем — теплообменник, который со временем течет. В свое время на моторах 1.6 и 1.8 считались не очень надежными модули зажигания. А еще проблемы случаются из-за не очень долговечной проводки и нарушения контактов в блоке управления двигателем. В общем, «пожилая» Astra H, как и Zafira В, – «любимый» автомобиль электриков. Но серьезных проблем атмосферные моторы не преподносят.

Изредка на рынке встречаются версии с турбомотором 2.0 с отдачей 170-240 л.с. Двигатель достаточно крепкий, надежность его неплоха, но вопрос в том, как на нем ездили последние 10 лет и не пытались ли «задуть» в него еще больше «лошадок».

Дизельные двигатели

Скажем сразу: если у Astra H более и менее удачные версии дизельных двигателей, но в случае с возрастными и хорошо поездившими машинами куда важнее текущее техническое состояние, а также стоимость ремонта или замены агрегата либо его узлов. Собственно говоря, важно убедиться, что топливная система исправна, нет проблем по турбонаддуву и EGR, если по заводу должен стоять сажевый фильтр, разобраться, что с ним сейчас (наверняка удален, но насколько грамотно?).

«Проходной» 1.3 CDTI (90 л.с.) – это, конечно же, итальянский MultiJet. Здесь основное внимание – приводу ГРМ (цепь живет до 200 тыс. км) и состоянию сажевого фильтра. Как правило, при пробегах свыше 200 тыс. км уже имеются вопросы по турбине.

Также Astra H оснащалась 1,9-литровыми CDTI мощностью 100/120/150 л.с., и это не что иное, как Fiat 1.9 JTD. Лучшим вариантом принято считать 120-сильный, но повторимся: здесь уже важнее текущее техническое состояние конкретного экземпляра.

Вообще дизельные двигатели Opel 1.7 CDTi могли оснащаться топливной аппаратурой Common Rail от двух производителей: Bosch и Denso. Второй вариант менее предпочтителен в силу гораздо меньшей развитости сервисной базы в нашей стране. Впрочем, по нашим данным, двигатели для Astra оснащались только аппаратурой Bosch. В целом система Common Rail надежна, но возраст есть возраст: со временем могут возникнуть проблемы по части поддержания давления в рампе (датчики и клапаны) или же по самому впрыску (топливные форсунки). Перспектива их появления также зависит от качества топлива и своевременного обслуживания.

Со временем может потребовать ремонта или замены турбина (по разным оценкам срок ее службы может составлять от 150 тыс. до 300 тыс. км). С возрастом и пробегами может дать знать о себе старая «болячка» моторов семейства 4EE2: рассыхаются резиновые уплотнители, в том числе пресловутые колечки форсунок, что приводит к течам технических жидкостей.

Трансмиссия

Весьма печально, что с надежными атмосферными моторами идет неудачная коробка F17, которая славится недолговечными подшипниками валов и не очень выносливым дифференциалом. Чем тяжелее автомобиль и чем мощнее двигатель, чем агрессивнее ездит владелец, тем выше риск появления проблем.

Вот дизельные версии с моторами 1.7 и 1.9 будут оснащены куда более прочной коробкой F23, у которой со временем разве что изнашивается механизм кулисы. Автомобили с 2,0-литровым турбомотором оснащались коробкой М32, которая тоже куда выносливее F17, но все же страдает от агрессивной езды – в зоне риска все те же подшипники. Также стоит обратить внимание, что мощные бензиновые и дизельные модификации оснащались сцеплением с двухмассовым маховиком, а его замена дешевой быть не обещает. Поэтому при проверке автомобиля перед покупкой коробке уделяем максимум внимания.

С «младшими» моторами Astra оснащалась роботизированной коробкой Easytronic. При работе она раздражает своей медлительностью, а в эксплуатации требует квалифицированного обслуживания (работу «автоматизированного» сцепления нужно проверять каждые 30 тыс. км). И кстати, создана она базе все той же F17! Впрочем, настройки управляющей электроники вряд ли позволят сильно нагружать «железо».

4-диапазонный «автомат» Aisin – вполне разумный вариант для покупки, особенно в случае с достаточно свежим автомобилем. При условии грамотной эксплуатации и своевременного обслуживания АКПП будет жить долго и не докучать проблемами. Жаль, что встречается эта коробка только на машинах с мотором 1.8, так что ее еще надо поискать. Дизельная Astra 1.9 CDTI могла оснащаться 6-ступенчатой АКП, которая также будет радовать надежностью при условии своевременного обслуживания.

Ходовая часть

Как и на всех предшествующих поколениях Astra, Opel не стал мудрить и спереди использовал стойки McPherson, сзади – обычную «балку». В итоге все очень просто, дешево, а главное – ресурсно. Благостную картину портят лишь ступичные подшипники, который ходят 60-70 тыс. км, меняются вместе со ступицами и поэтому стоят недешево. Не очень долговечны и опорные подшипники. А если говорим про универсал Caravan или компактвэн Zafira, то высока вероятность, что просевшие задние пружины уже будут проситься на замену. Впрочем, тут зависит от того, как часто машина ездила с перегрузом.

Наш вердикт

В целом автомобиль получился долговечным: при должном уходе кузов, двигатель и ходовая часть «живут» долго и счастливо. Жаль, этого нельзя сказать про коробку передач наиболее популярных бензиновых версий. А еще и электрика не образец надежности. Но все же главные враги – время и предыдущие владельцы-разгильдяи. Хорошо еще, что для нашего региона Astra H выпускали аж до 2014 года – больше шансов найти «живой» экземпляр. Главное – не нарваться на «рабочую лошадку», а таких среди подержанных экземпляров немало.

«Скандинавский пакет»

Споры на тему ездить или нет с ближним светом или дневным светом (DRL) уже закончены, Вам остается просто выбрать удобный вариант, благо Астра предлагает много вариантов.

ЧТО ЭТО ТАКОЕ?

Так называемый «скандинавский пакет» — это фактически автоматическое включение ближнего света при определенных условиях в начале движения, например:

- при снятии машины с «ручника»

- при включении зажигания

- при запуске двигателя

Опция названа так, потому что в скандинавский странах законодательно закреплено правило постоянного использования ближнего света при движении. В Opel Astra H скандинавский пакет включается с помощью TECH’а.

Фото предоставил © Jedi-Master

Алгоритмы работы

Информацию предоставил © Дилер

Дальний свет включается только в положении переключателя «Ближний свет»

Включение/выключение «Скандинавского пакета»

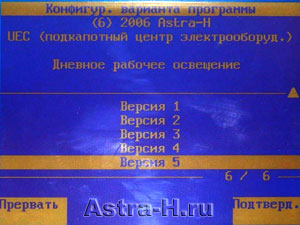

Данный агоритм работает только в Версии №5 .

Если переключатель ближнего света повернуть в положение «ближний свет», а потом сразу в положение «Выкл.», то алгоритм работы становится стандлартным и не меняется даже после перезапуска двигателя. Чтобы снова включить «скандинавский пакет» после запуска двигателя, необходимо повторить описанную выше операцию.

Если установлен датчик света

Если переключатель габаритов стоит в положении «Auto», то «днем» (при хорошей освещенности) алгоритм работы освещения автомобиля совпадает с режимом в положении переключателя освещения «О», а «ночью» с режимом переключателя освещения «Ближний свет».

ПРОГРАММИРОВАНИЕ

Программирование производится только при помощи Tech2. Алгоритм следующий:

Информацию предоставил © Сергей Н.

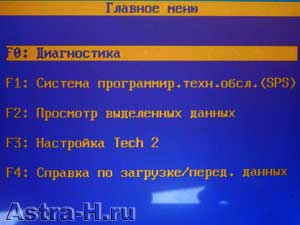

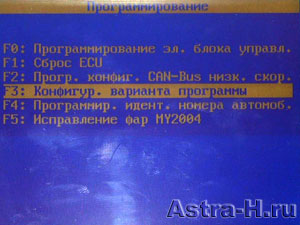

1. Подключаем Tech2 к диагностической колодке около ручника |

2. Выбираем «Диагностику» |

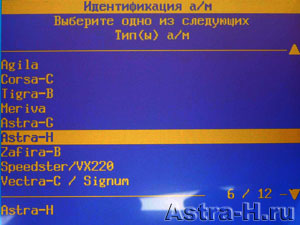

3. Год выпуска автомобиля. |

4. И его марку. |

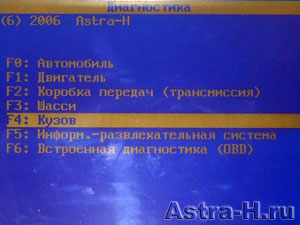

5. Пункт меню «Кузов» |

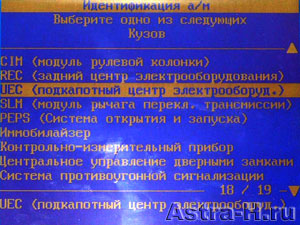

6. Пункт меню «UEC» |

7. Пункт меню «Программирование» |

8. Пункт меню «Конфигурация варианта программы» |

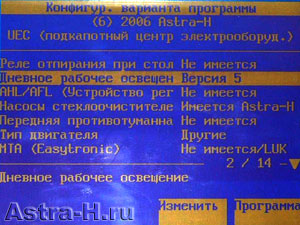

9. Пункт меню «Дневное рабочее освещение» |

10. И необходимую версию «Скандинавского пакета» |

Для корректной работы задних габаритов не забудьте повторить ту же процедуру для REC («заднего центра электрооборудования») см .фото 6

Панель приборов Opel Astra H

Расположение органов управления автомобилем Opel Astra показано на рис. 1. Для удобства пользования на ручки, кнопки и контрольно-измерительные приборы, расположенные на панели приборов и других дополнительных панелях управления, нанесены символы функционального назначения.

Рис. 1. Панель приборов и органы управления

На панели приборов расположены следующие органы управления и контрольно-измерительные приборы:

1 — блок управления наружным освещением, яркостью подсветки комбинации приборов, задними противотуманными фонарями и электрокорректором света фар.

Поворотом рукоятки переключателя наружного освещения включают габаритный, ближний или дальний свет.

Нажатием на левую нижнюю кнопку блока включают свет в задних противотуманных фонарях. При повторном нажатии на кнопку противотуманные фонари выключаются. Аналогично включают и выключают противотуманные фары (если они установлены), нажав на левую верхнюю кнопку блока (на фото вместо кнопки установлена заглушка).

Нажатием на правую нижнюю рукоятку блока разблокируют регулятор электрокорректора света фар (при этом рукоятка выдвигается из блока).

Поворотом рукоятки регулятора в зависимости от загрузки автомобиля изменяют угол наклона пучка света фар таким образом, чтобы исключить ослепление водителей встречного транспорта. Совмещая метку на рукоятке регулятора и цифры на шкале, выбирают соответствующую регулировку положения фар при следующих вариантах загрузки автомобиля:

0 — один водитель или водитель и пассажир на переднем сиденье;

2 — все места заняты и груз в багажнике;

3 — один водитель и груз в багажнике.

По окончании регулировки заблокируйте регулятор, утопив его рукоятку в блок.

Нажатием на правую верхнюю рукоятку блока разблокируют регулятор яркости подсветки комбинации приборов и информационного дисплея (при этом рукоятка выдвигается из блока).

Для увеличения яркости подсветки поверните рукоятку в направлении знака «+» и удерживайте ее в этом положении до достижения требуемой яркости (яркость подсветки изменяется автоматически). Аналогично уменьшайте яркость подсветки, повернув рукоятку регулятора в направлении знака «-». По окончании регулировки заблокируйте регулятор, утопив его рукоятку в блок.

2 и 12 — боковые сопла системы вентиляции и отопления салона.

Поворотом рукоятки А изменяют интенсивность потока воздуха, причем в крайнем нижнем положении рукоятки поток воздуха максимален, а в крайнем верхнем — перекрыт (на рукоятке виден символ «O»). Рукояткой Б регулируют направление потока воздуха.

3 и 13 — сопла обдува стекол дверей.

4 — рычаг переключателя наружного освещения и указателей поворота. Рычаг переключателя может занимать следующие положения:

I — включены указатели правого поворота (фиксированное положение);

II — включены указатели левого поворота (фиксированное положение);

При перемещении рычага в положение «I» или «II» в комбинации приборов загорается мигающим светом контрольная лампа 10 или 13 (рис. 2). При возврате рулевого колеса в положение прямолинейного движения рычаг автоматически устанавливается в исходное положение. При смене полосы движения для включения указателя поворота достаточно нажать на рычаг в направлении положения «I» или «II» только до момента ощутимого сопротивления, не фиксируя рычаг, и отпустить. Указатели поворота в этом случае мигнут три раза.

Рис. 2. Комбинация приборов

Для переключения между дальним и ближним светом фар передвиньте рычаг переключателя к рулю на две позиции и отпустите.

При включении дальнего света в комбинации приборов загорается контрольная лампа 22 (рис. 2).

Для сигнализации дальним светом фар передвиньте рычаг переключателя на одну позицию к рулю (рукоятка переключателя, наружного освещения в блоке управления 1 (см. рис. 1) наружного освещения должна находиться в положении «Включен ближний/дальний свет») и отпустите.

При включении дальнего света в комбинации приборов также загорается контрольная лампа 22 (см. рис. 2).

По заказу может быть введена функция «освещение дороги к дому». Если при выключенном зажигании и открытой двери водителя передвинуть рычаг переключателя на одну позицию к рулевому колесу, а затем отпустить, то активируется функция задержки выключения фар — включится ближний свет фар и свет фонарей света заднего хода, который выключится только через 30 мин после закрытия последней двери. Для того чтобы выключить фары, переместите рычаг переключателя на одну позицию к рулевому колесу и отпустите еще раз.

Если выключатель (замок) зажигания находится в положении «О» или «I», при включенном наружном освещении в момент открытия двери водителя включится зуммер, напоминающий о необходимости выключить освещение.

По заказу может быть введена функция стояночного света. При парковке автомобиля можно включить передний и задний габаритные огни с одной стороны автомобиля, для чего при выключенном зажигании и рукоятке переключателя наружного освещения в блоке управления 1 (см. рис. 1) наружного освещения в положении «0» поверните рычаг переключателя наружного освещения и указателей поворота в нужную сторону. При этом включится зуммер и одновременно загорятся контрольные лампы 10 и 13 (см. рис. 2) в комбинации приборов.

По заказу в спицы рулевого колеса могут быть установлены пульты дистанционного управления развлекательной системой и аудиосистемой.

7 — рычаг переключателя стеклоочистителя и омывателя ветрового окна и окна двери задка (на автомобилях с кузовами универсал и хэтчбек).

Включает электрические цепи при включенном зажигании и может быть установлен в следующие положения:

1 — стеклоочиститель выключен;

2 — щетки стеклоочистителя совершат один цикл;

3 — включен прерывистый режим работы стеклоочистителя. Для регулировки времени задержки между циклами (если эта опция установлена) нажмите на рычаг вниз из положения 1, выждите желаемый промежуток времени и установите рычаг в положение 3;

4 — включена первая (низкая) скорость стеклоочистителя;

5 _ включена вторая (высокая) скорость стеклоочистителя.

В зависимости от комплектации вместо стеклоочистителя с прерывистым режимом может быть установлен стеклоочиститель с автоматическим режимом работы. В этом случае при установке рычага переключателя в положение 3 активируется автоматический режим.

При перемещении рычага к рулевому колесу на одну позицию включатся очистители и омыватели ветрового стекла и стекол фар (если установлены).

При перемещении рычага от рулевого колеса на одну позицию включатся очиститель и омыватель стекла двери задка. При удерживании рычага в этом положении включится омыватель стекла двери задка на все время удерживания рычага.

Стеклоочиститель окна двери задка включится автоматически (зависит от комплектации) при включении передачи заднего хода, если рычаг стеклоочистителя находится в положении «2», «3» или «4».

8 — выключатель обогрева сиденья водителя.

В зависимости от требуемой степени обогрева сиденья нажмите на кнопку выключателя один или несколько раз. При каждом нажатии степень обогрева увеличивается и в кнопке загорается еще один сигнализатор. Для выключения обогрева нажимайте на кнопку несколько раз до тех пор, пока не погаснут все сигнализаторы.

Аналогичный выключатель установлен в облицовочной накладке панели приборов справа симметрично продольной оси автомобиля Опель Астра. Он служит для включения обогрева сиденья переднего пассажира и функционирует по тому же алгоритму, что и выключатель обогрева сиденья водителя. По заказу в общих блоках с выключателями обогрева сидений водителя и переднего пассажира могут быть установлены выключатели системы контроля падения давления в шинах, парктроника, спортивного режима, центрального замка.

9 — центральный информационный дисплей.

На дисплей выводится время, дата и наружная температура. В зависимости от комплектации автомобиля дисплей служит для получения информации от бортового компьютера (если он установлен), для визуального контроля при управлении аудиосистемой и системой отопления (кондиционирования) салона, а также развлекательной системой (если перечисленные системы установлены на автомобиле).

10 — выключатель аварийной сигнализации.

При нажатии на клавишу выключателя загораются мигающим светом все указатели поворота и соответствующие им контрольные лампы, установленные в комбинации приборов. При повторном нажатии на клавишу сигнализация отключается.

Аварийная сигнализация работает при любом положении ключа в выключателе (замке) зажигания.

Служит для хранения мелких вещей и открывается при нажатии на ручку замка вверх.

14 и 27 — пульты управления электростеклоподъемниками и наружными зеркалами заднего вида. В соответствующих подразделах подробно описаны приемы управления стеклоподъемниками и зеркалами.

15 — центральные сопла системы вентиляции и отопления салона.

Алгоритм управления потоком и интенсивностью воздуха через центральные сопла такой же, что и для боковых сопел 2 и 12.

16 — панель управления аудиосистемой.

Помимо органов управления аудиосистемой на панели 16 в зависимости от комплектации автомобиля могут быть установлены органы управления информационно-развлекательной системой и бортовым компьютером.

17 — блок управления системой отопления (кондиционирования) и вентиляции салона.

18 — рычаг управления коробкой передач.

19 — рычаг стояночного тормоза.

Для того чтобы затормозить автомобиль Opel Astra стояночным тормозом, поднимите рычаг до упора вверх — в комбинации приборов загорится красным светом сигнальная лампа 3 (см. рис. 2).

Для того чтобы растормозить автомобиль, потяните рычаг немного вверх, нажмите на кнопку в торце рукоятки рычага.

Опустите рычаг до упора вниз контрольная лампа должна погаснуть.

23 — выключатель (замок) зажигания, объединенный с противоугонным устройством, расположен с правой стороны рулевой колонки.

Ключ в замке может занимать одно из четырех положений:

— 0 (блокировка) _ зажигание выключено, при вынутом ключе включено противоугонное устройство;

Для гарантированного блокирования вала рулевого управления поверните рулевое колесо вправо или влево до щелчка.

Для выключения противоугонного устройства вставьте ключ в выключатель зажигания и слегка поворачивая рулевое колесо вправо-влево, поверните ключ в положение «I».

Не выключайте зажигание и не вынимайте ключ из замка во время движения — рулевое управление будет заблокировано и автомобиль станет неуправляемым.

— I (дополнительное оборудование) — зажигание выключено, ключ не вынимается, рулевое управление разблокировано. Включены цепи питания звукового сигнала, наружного освещения, сигнализации дальним светом фар, радиооборудования, прикуривателя и пр.;

— II (включено) — зажигание включено, ключ не вынимается, рулевое управление разблокировано. Включены зажигание, приборы и все электрические цепи;

— III (стартер) — включены зажигание и стартер, ключ не вынимается, рулевое управление разблокировано. Это положение ключа нефиксированное, при отпускании ключ под действием усилия пружины возвращается в положение «II».

24 — выключатель звукового сигнала.

Для того чтобы включить звуковой сигнал, нажмите на любое место центральной накладки рулевого колеса.

Источник

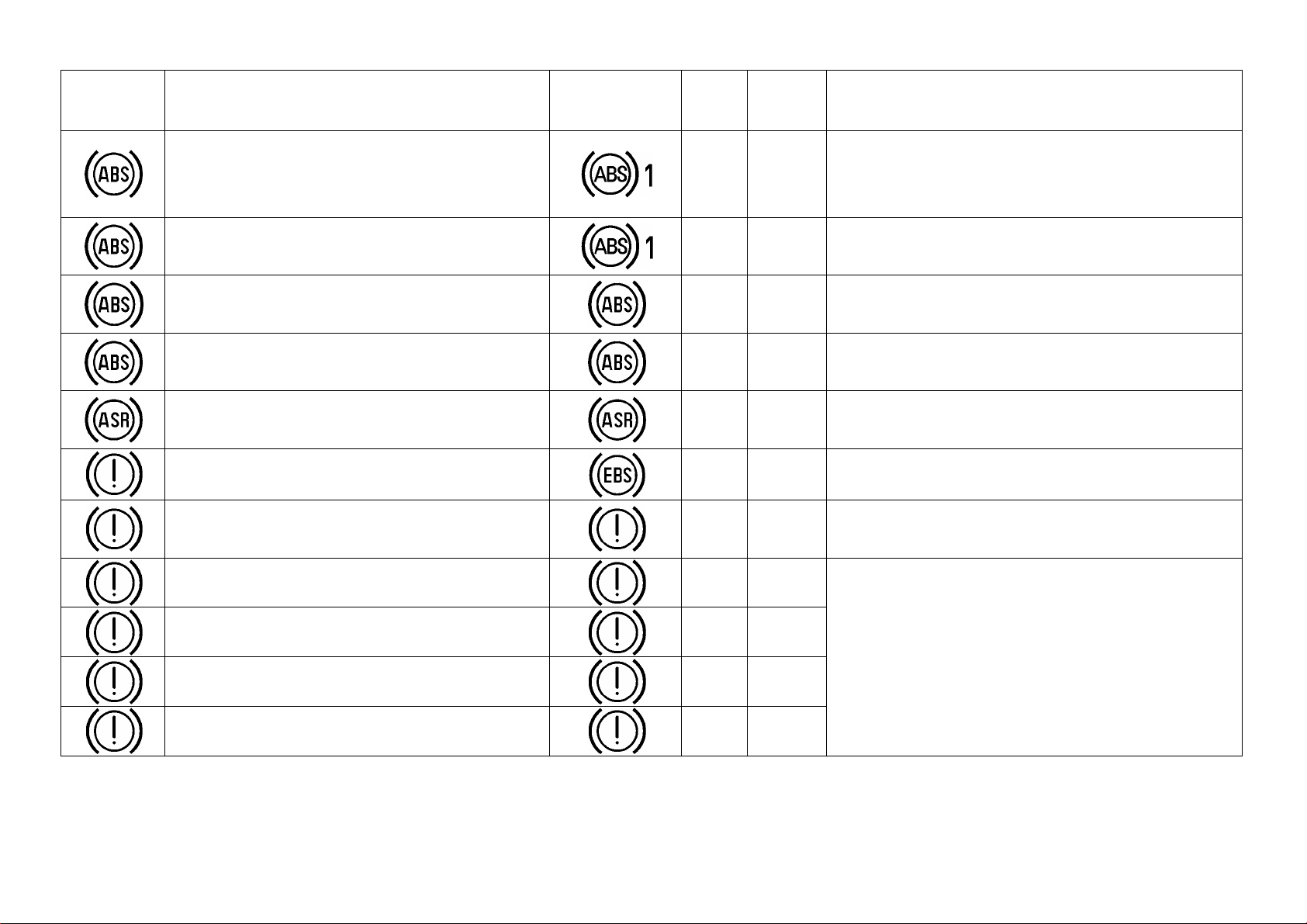

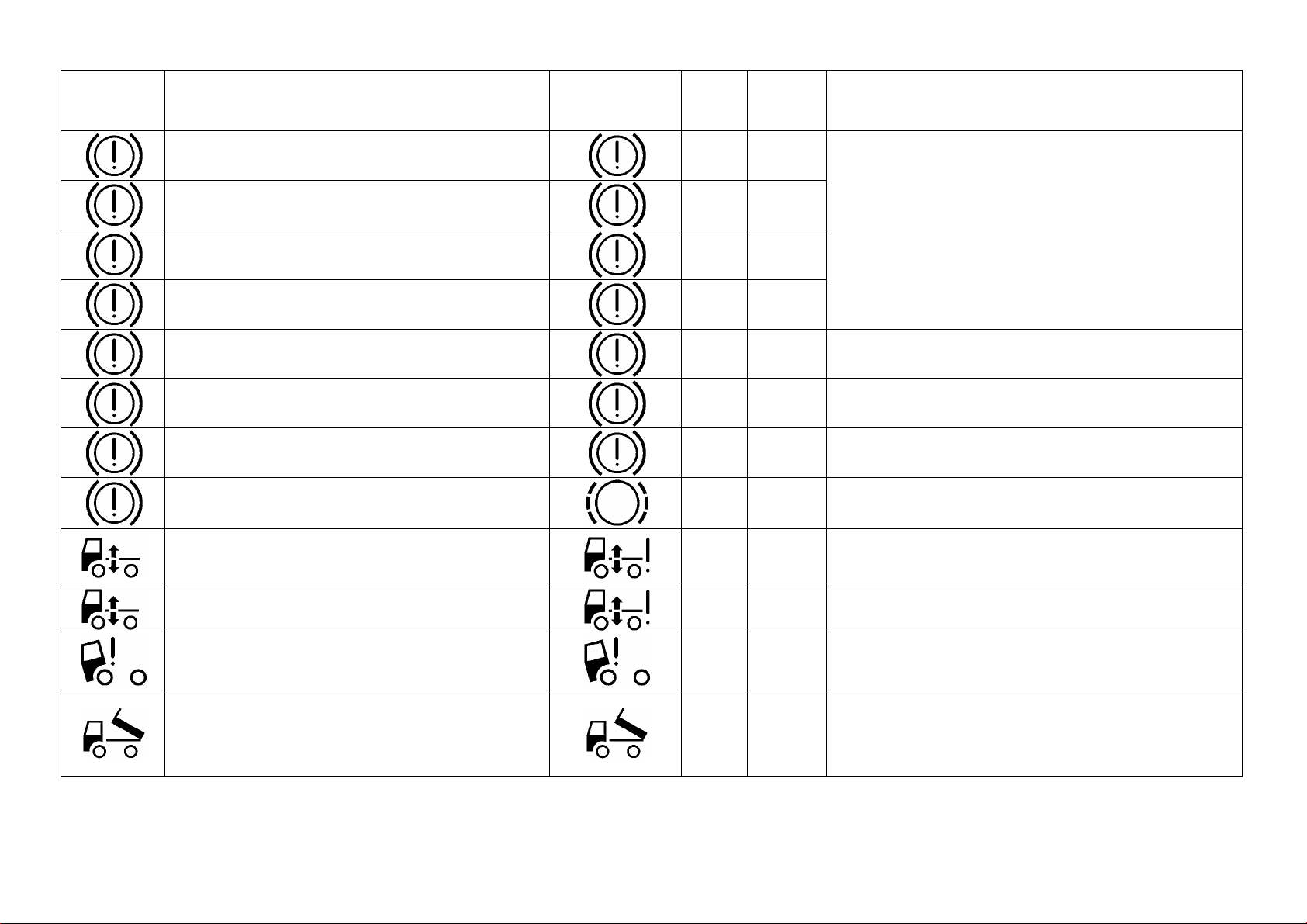

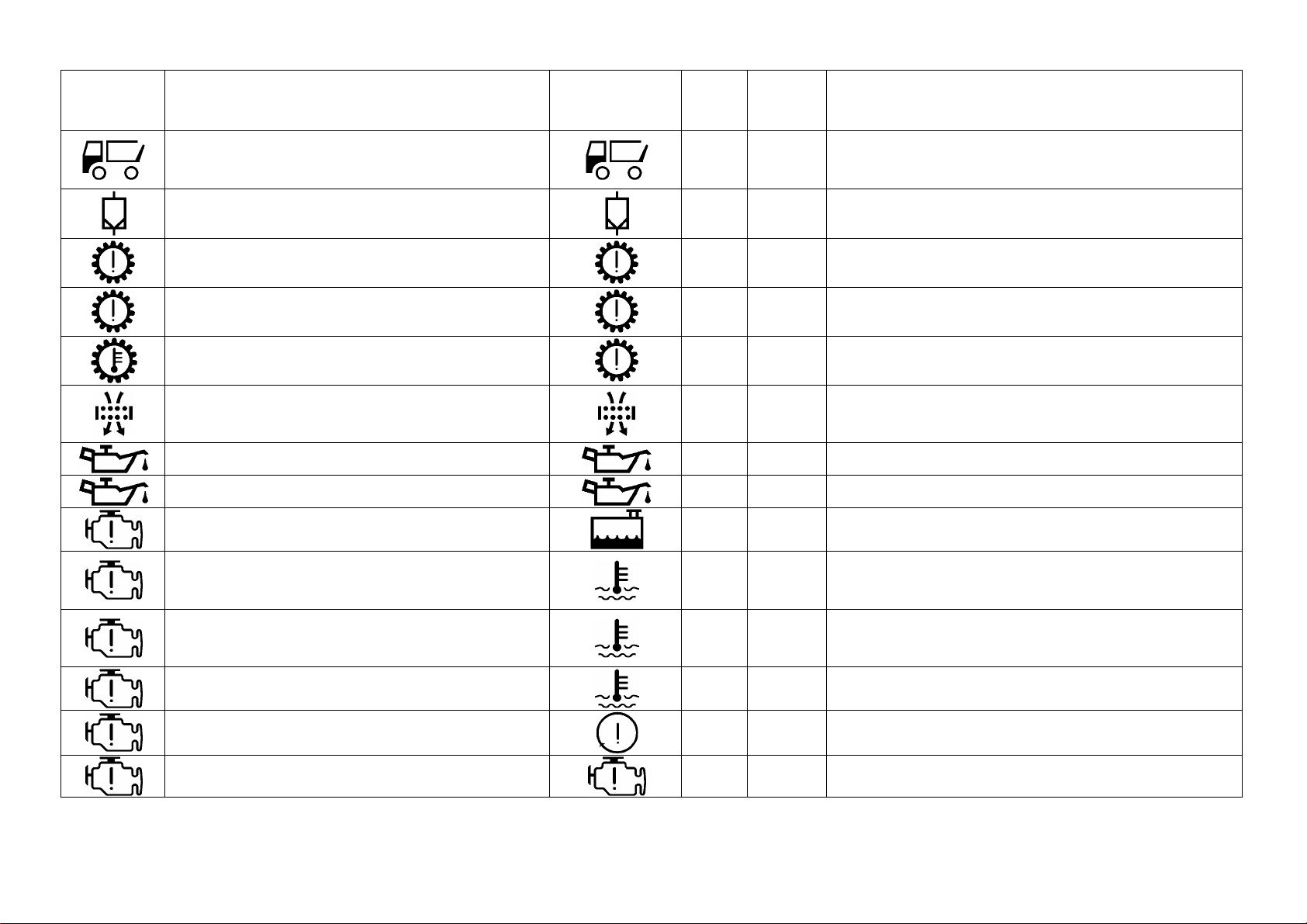

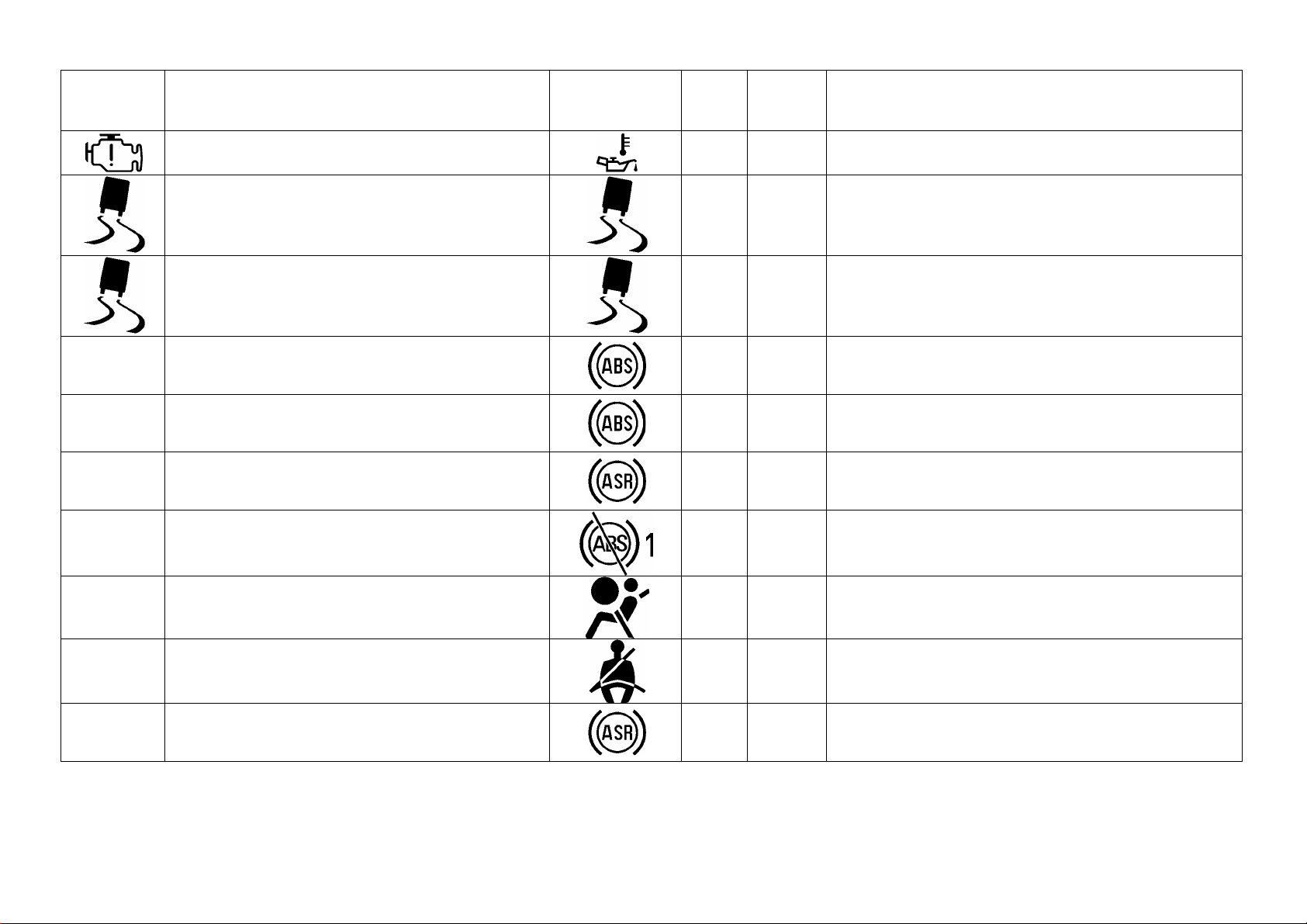

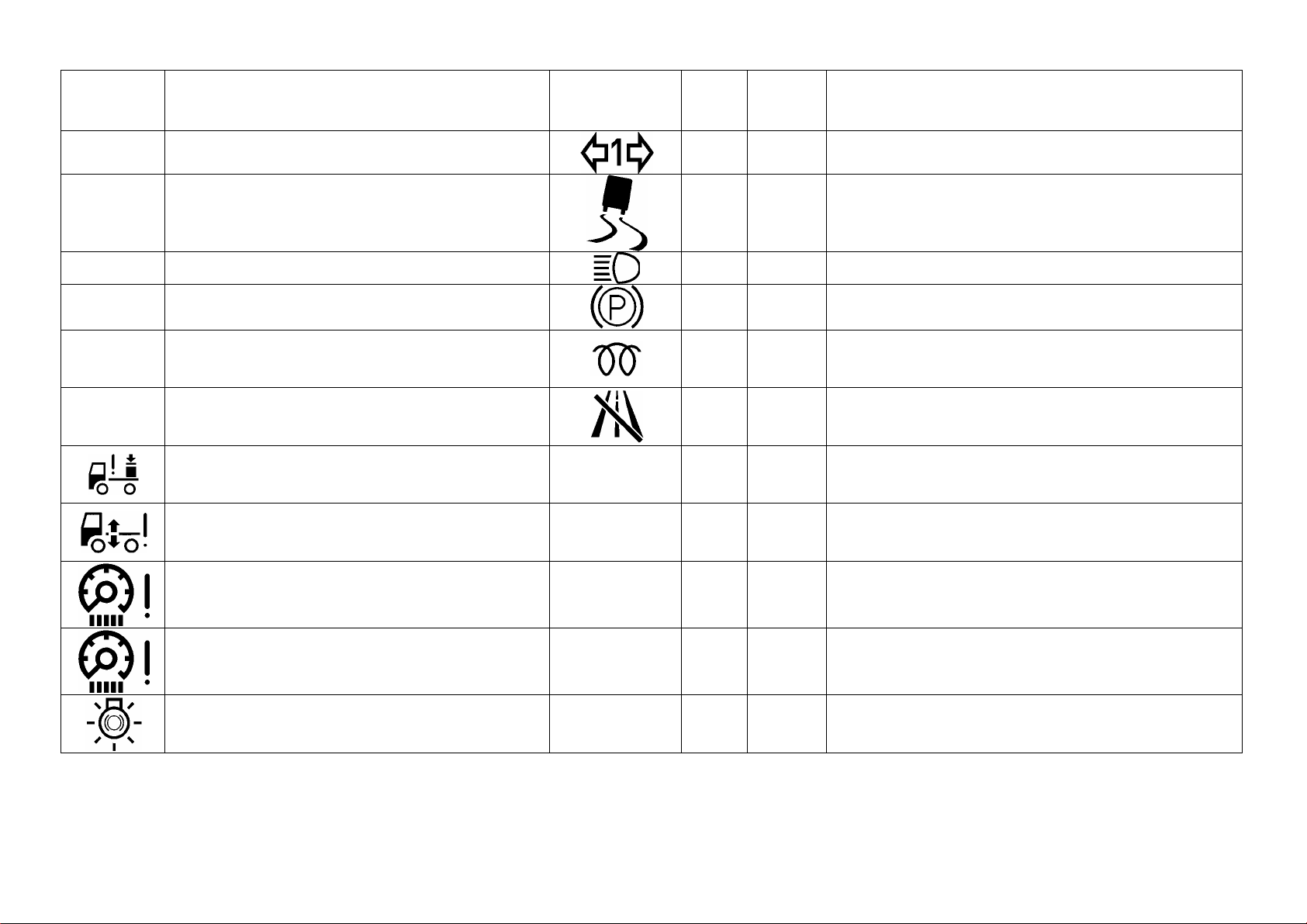

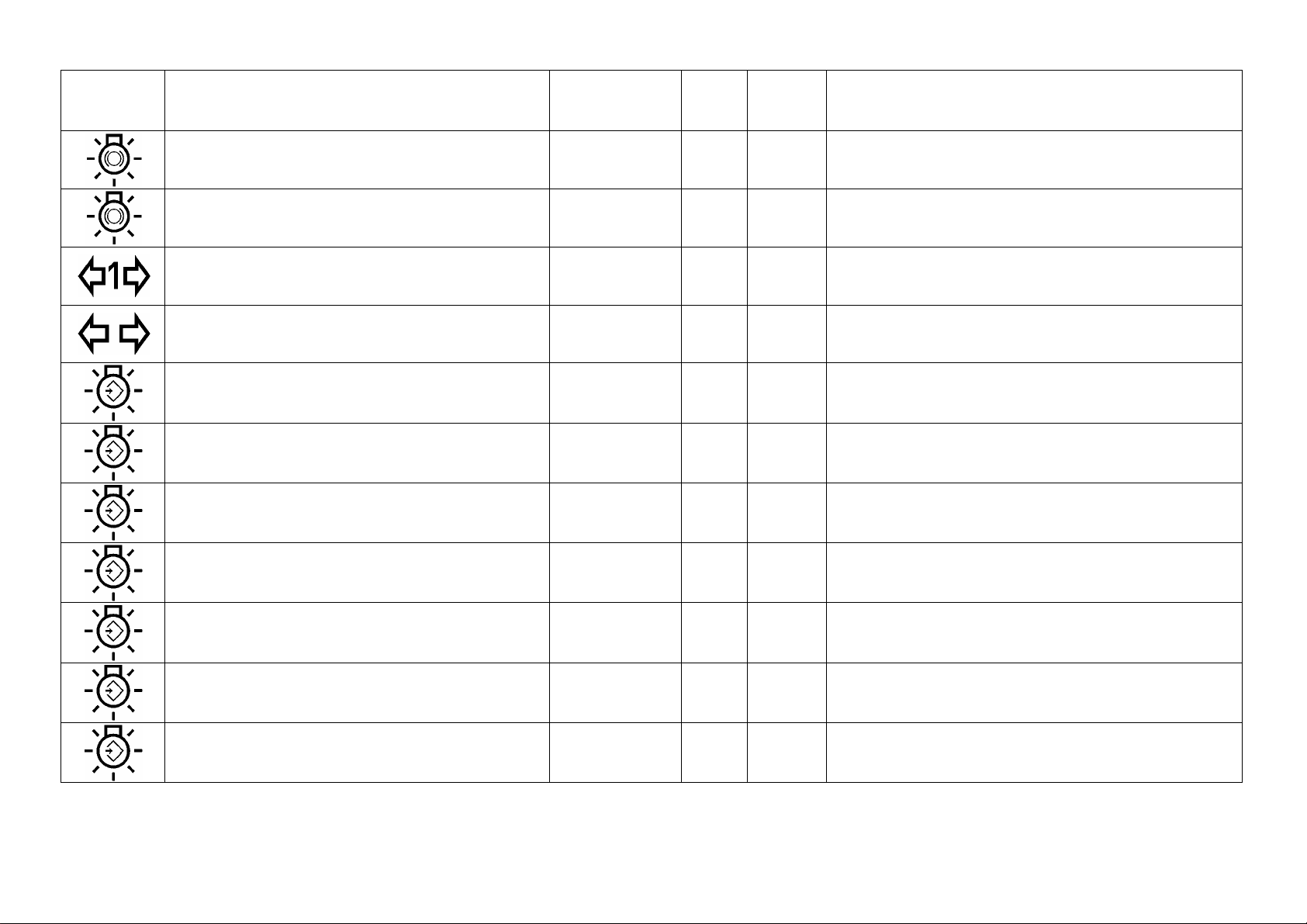

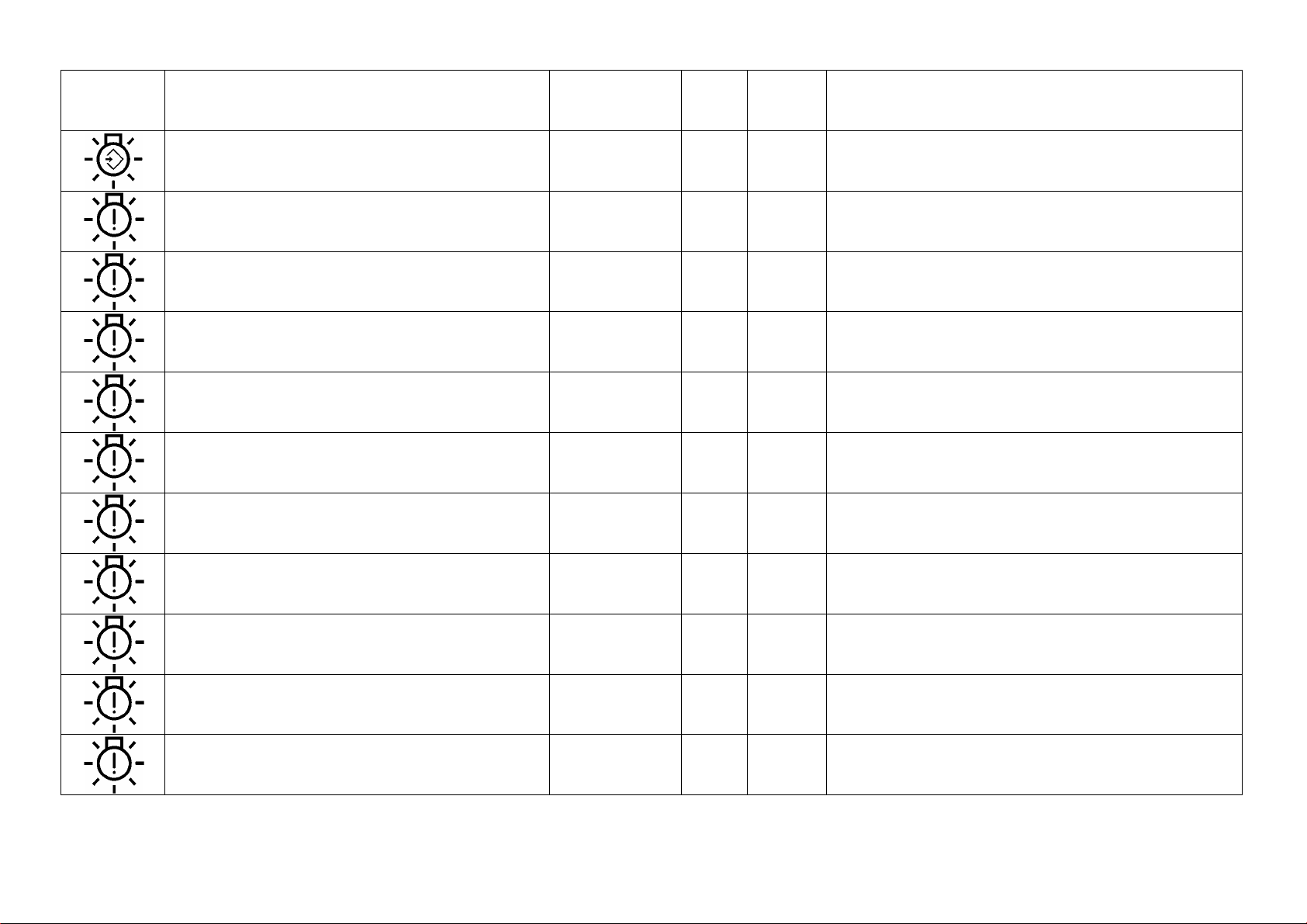

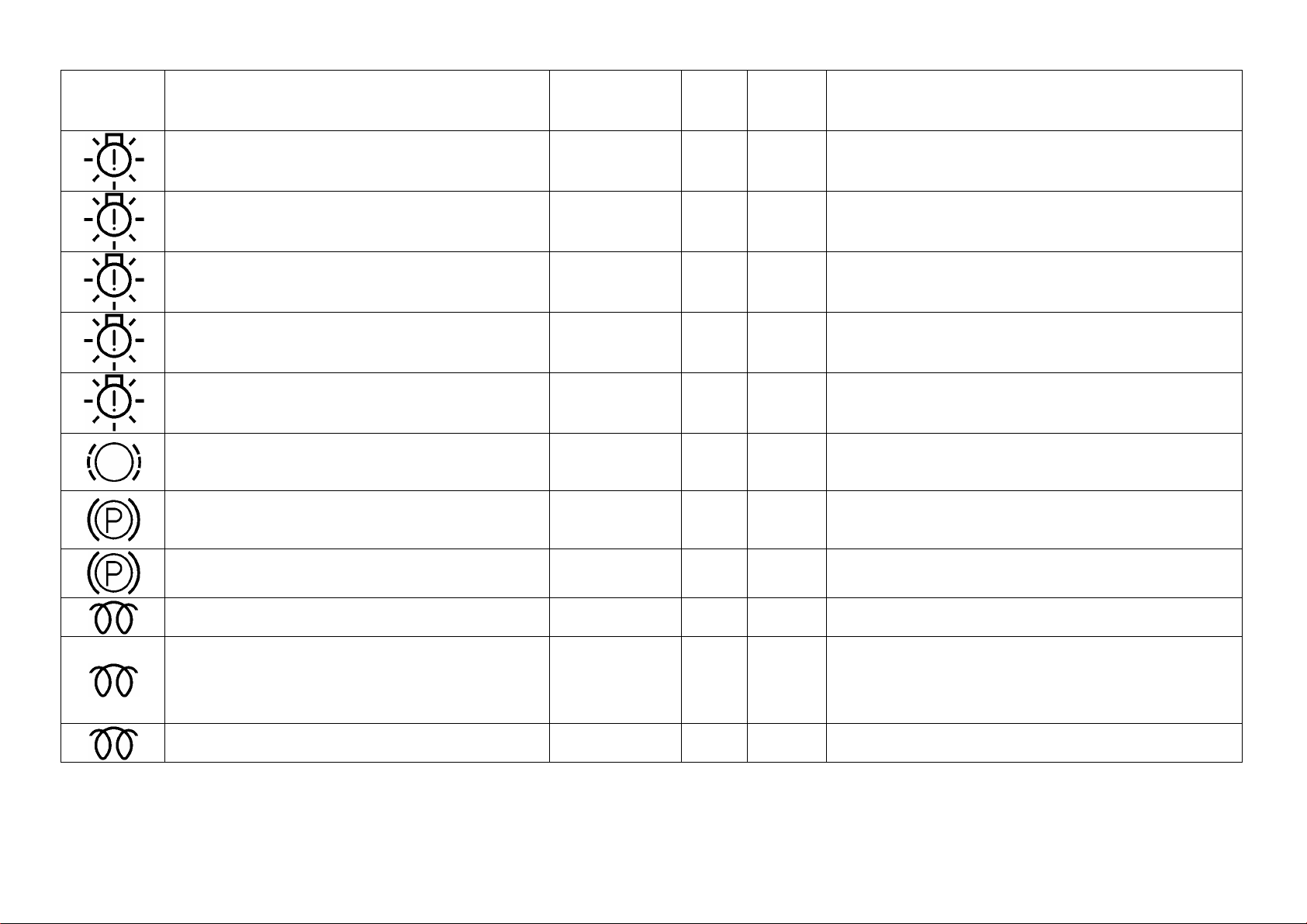

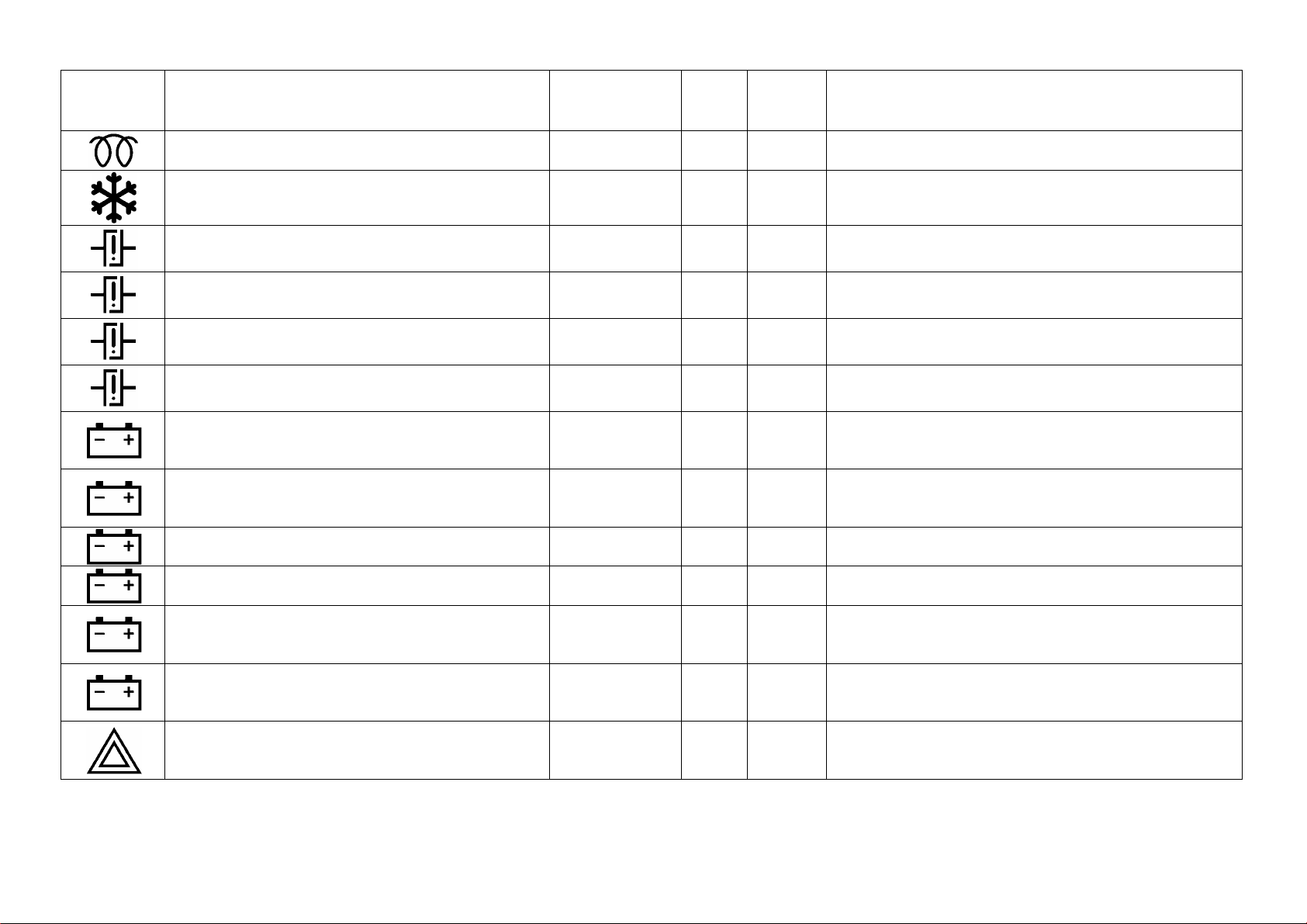

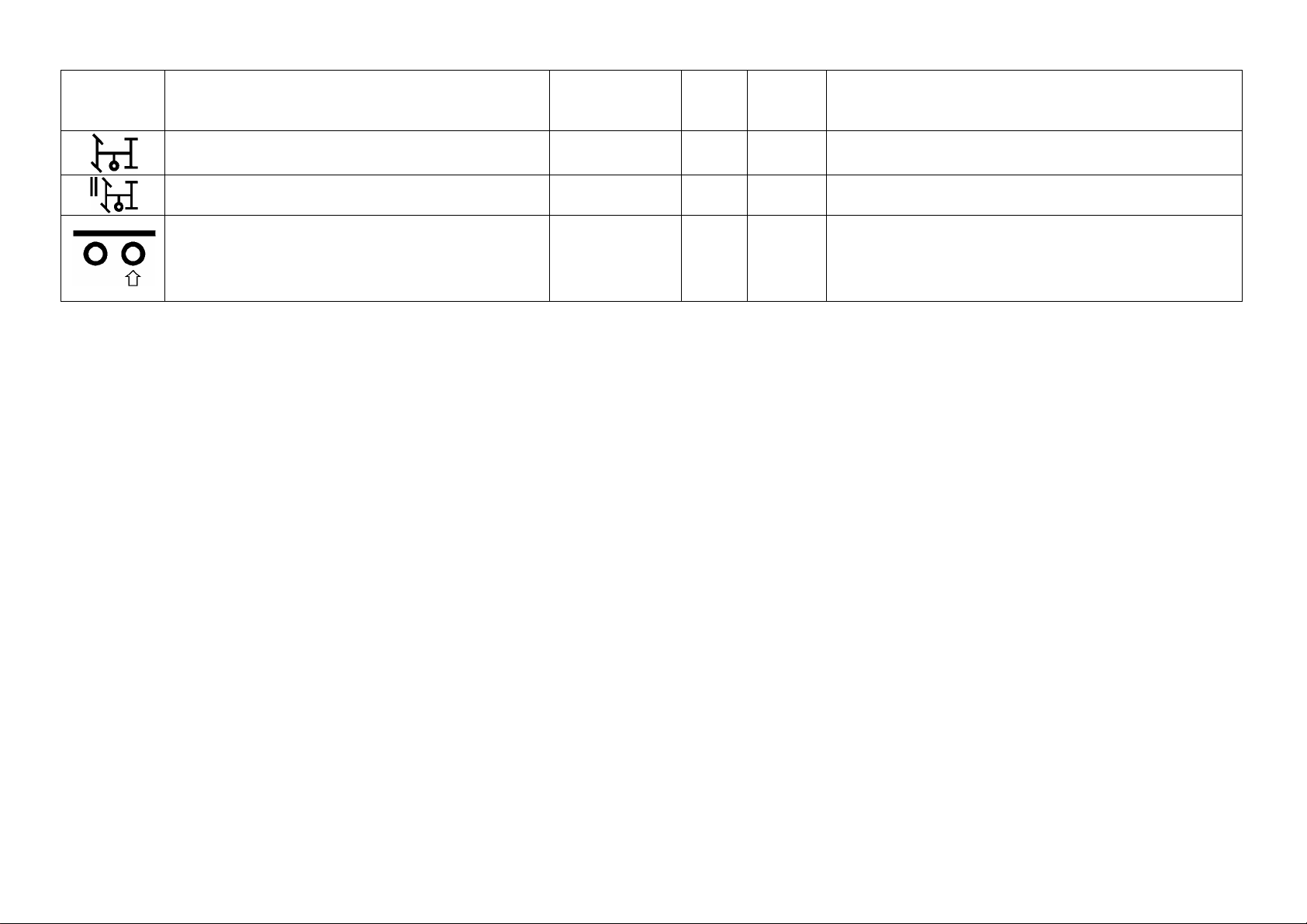

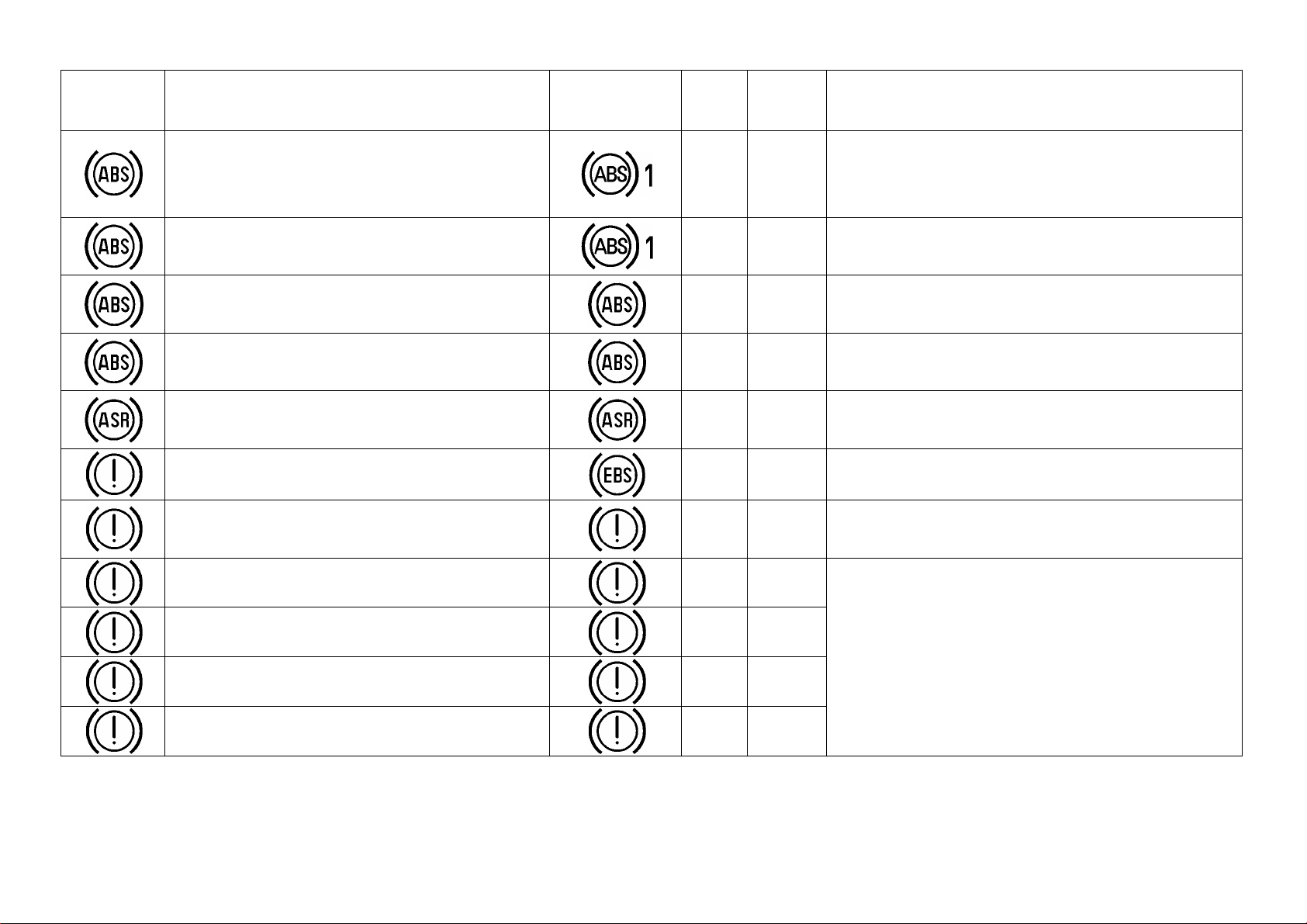

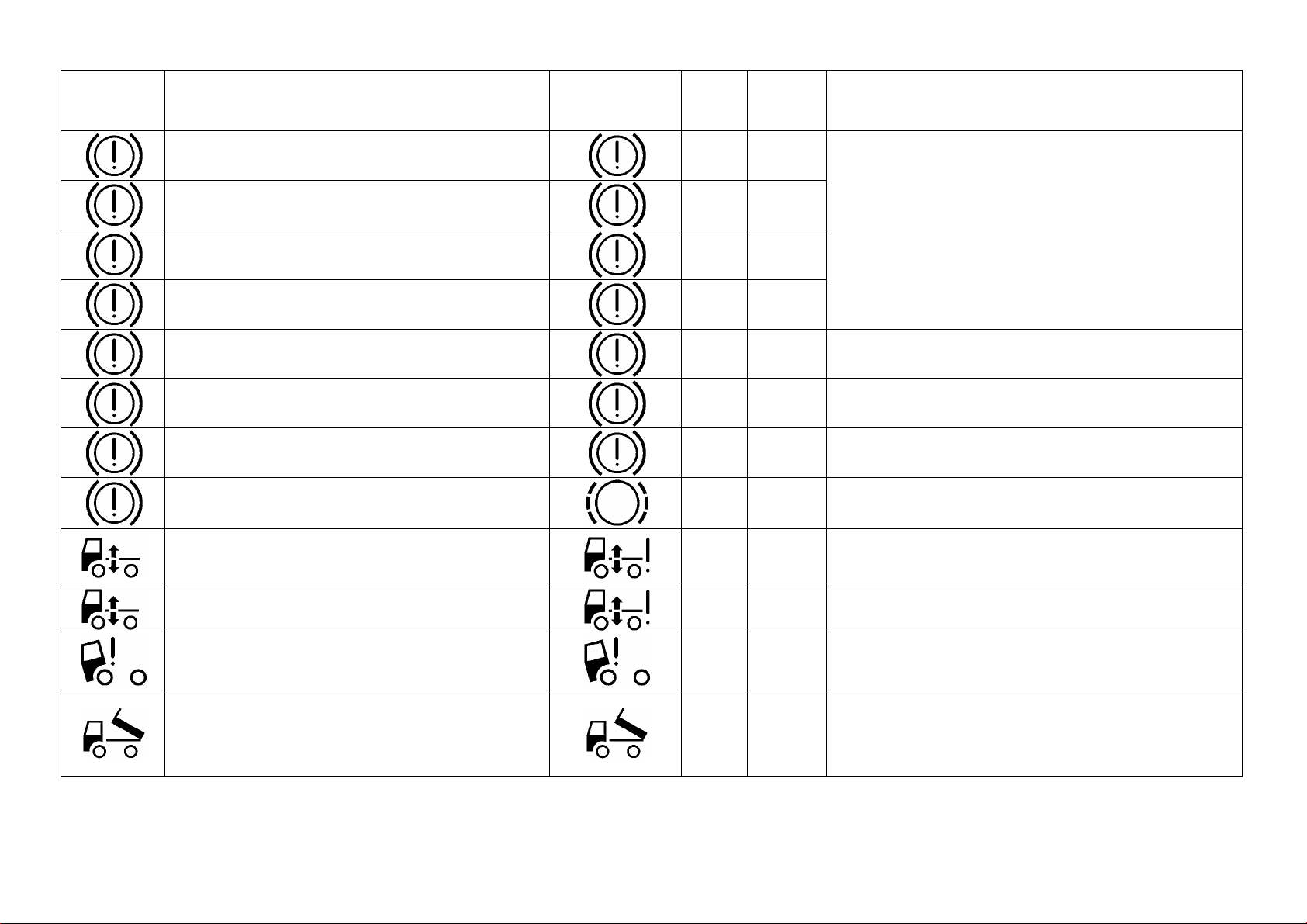

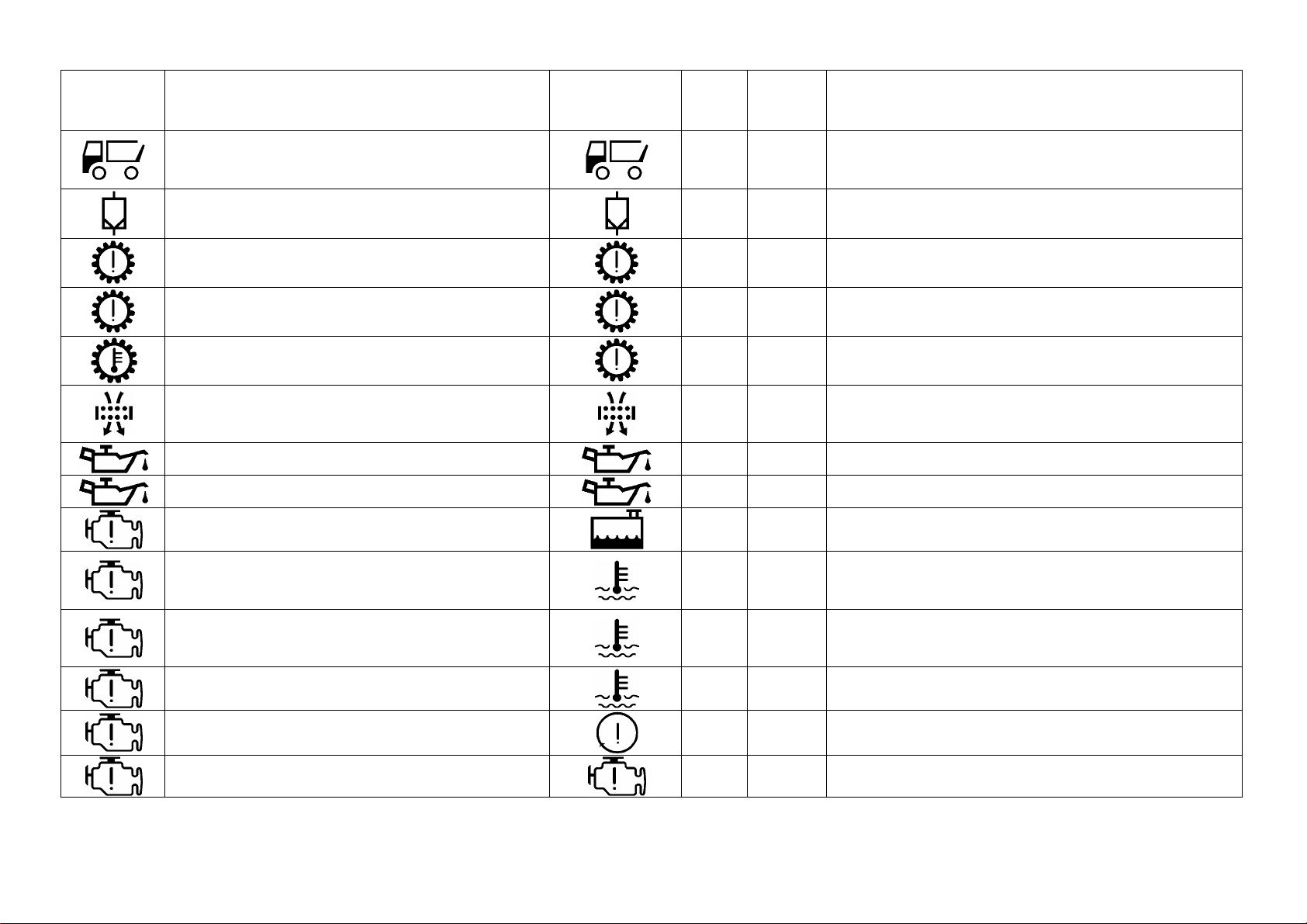

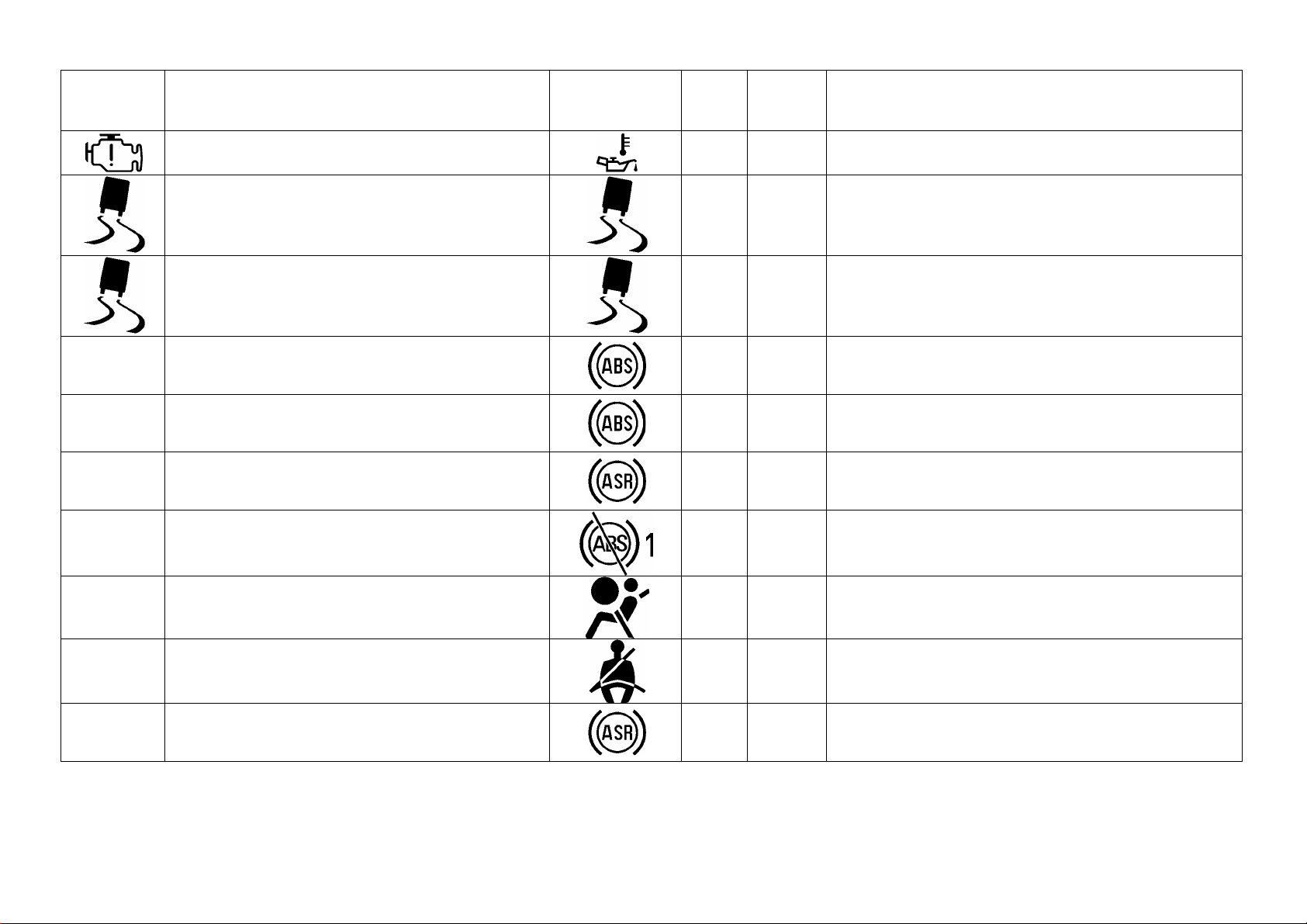

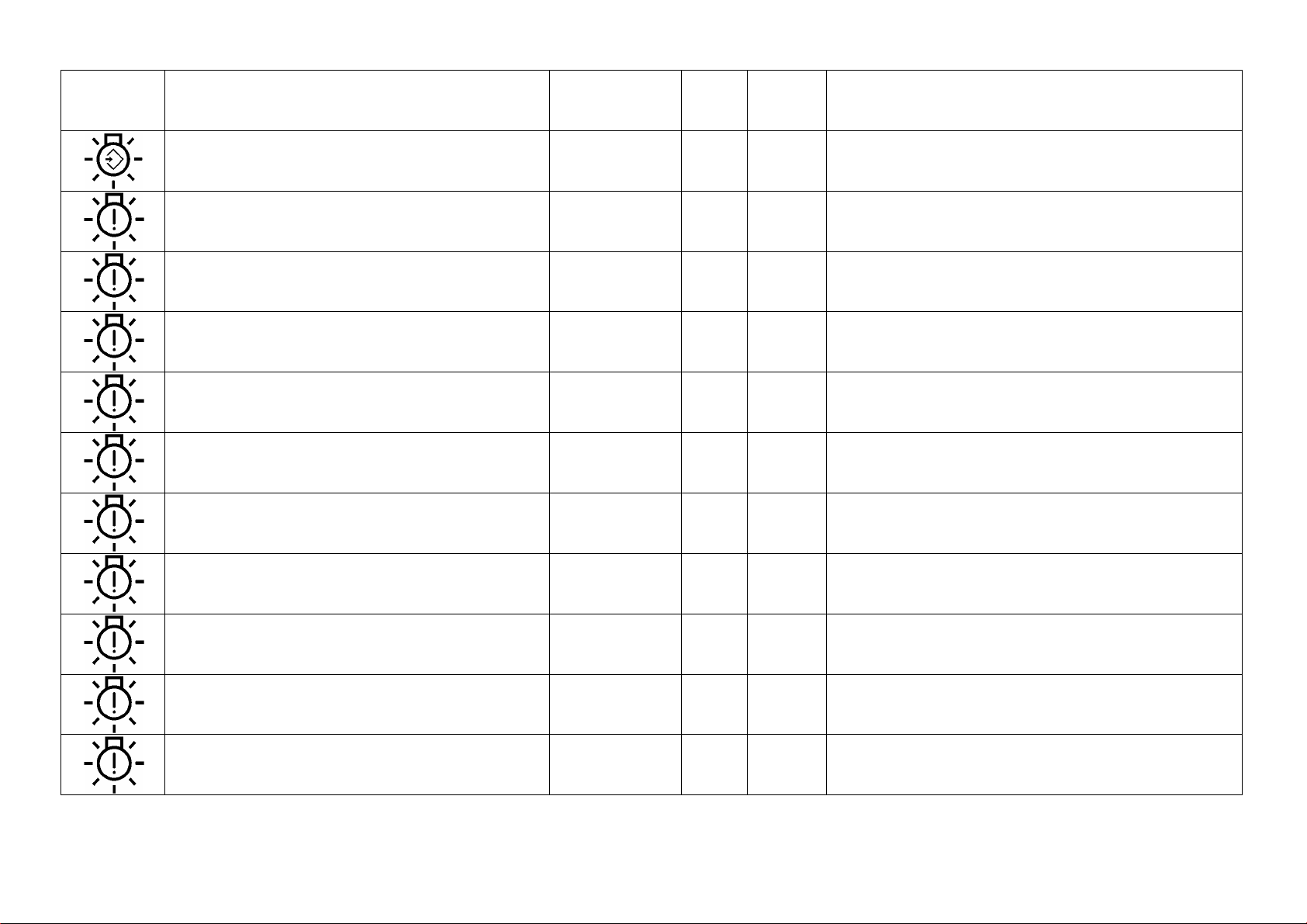

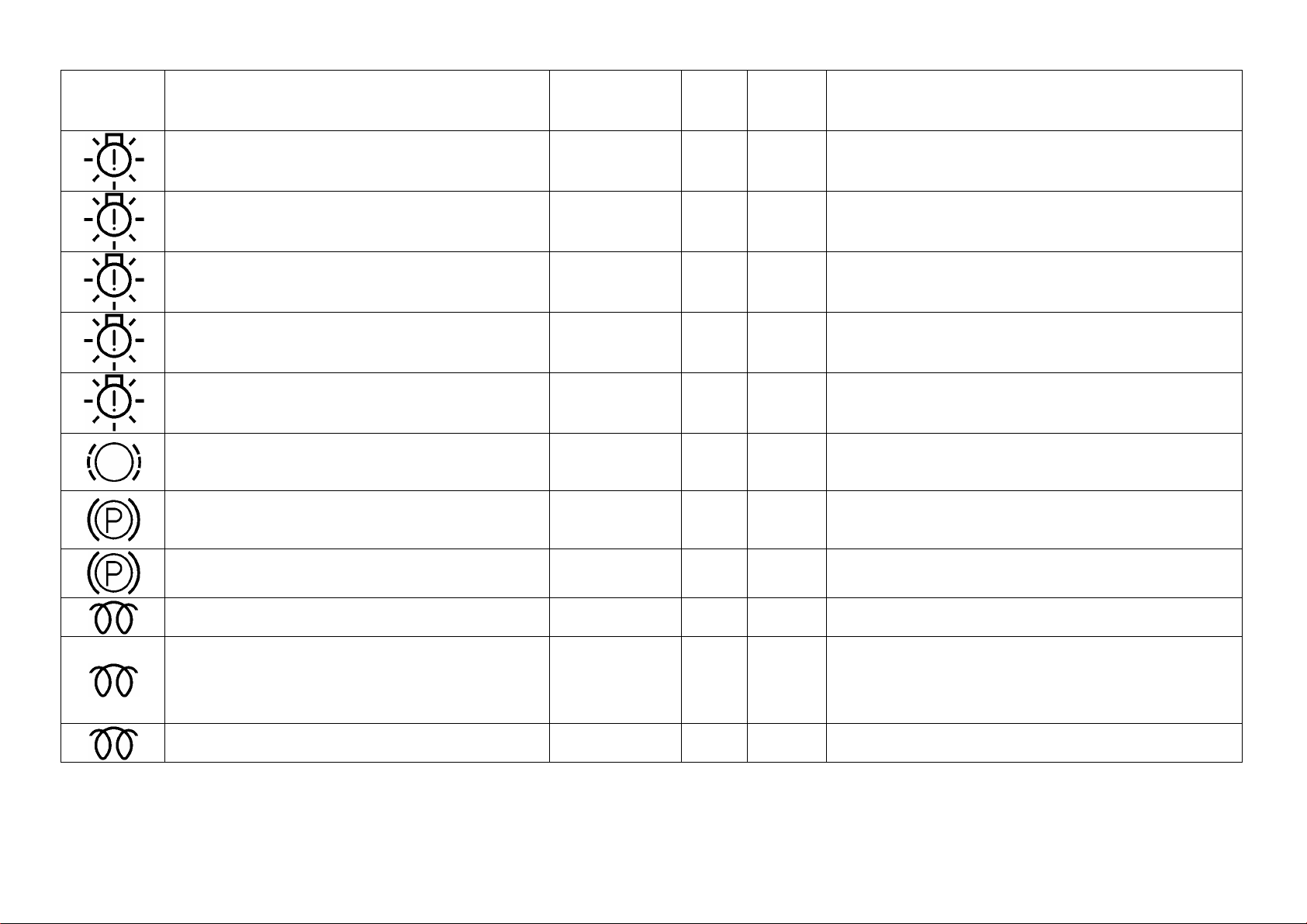

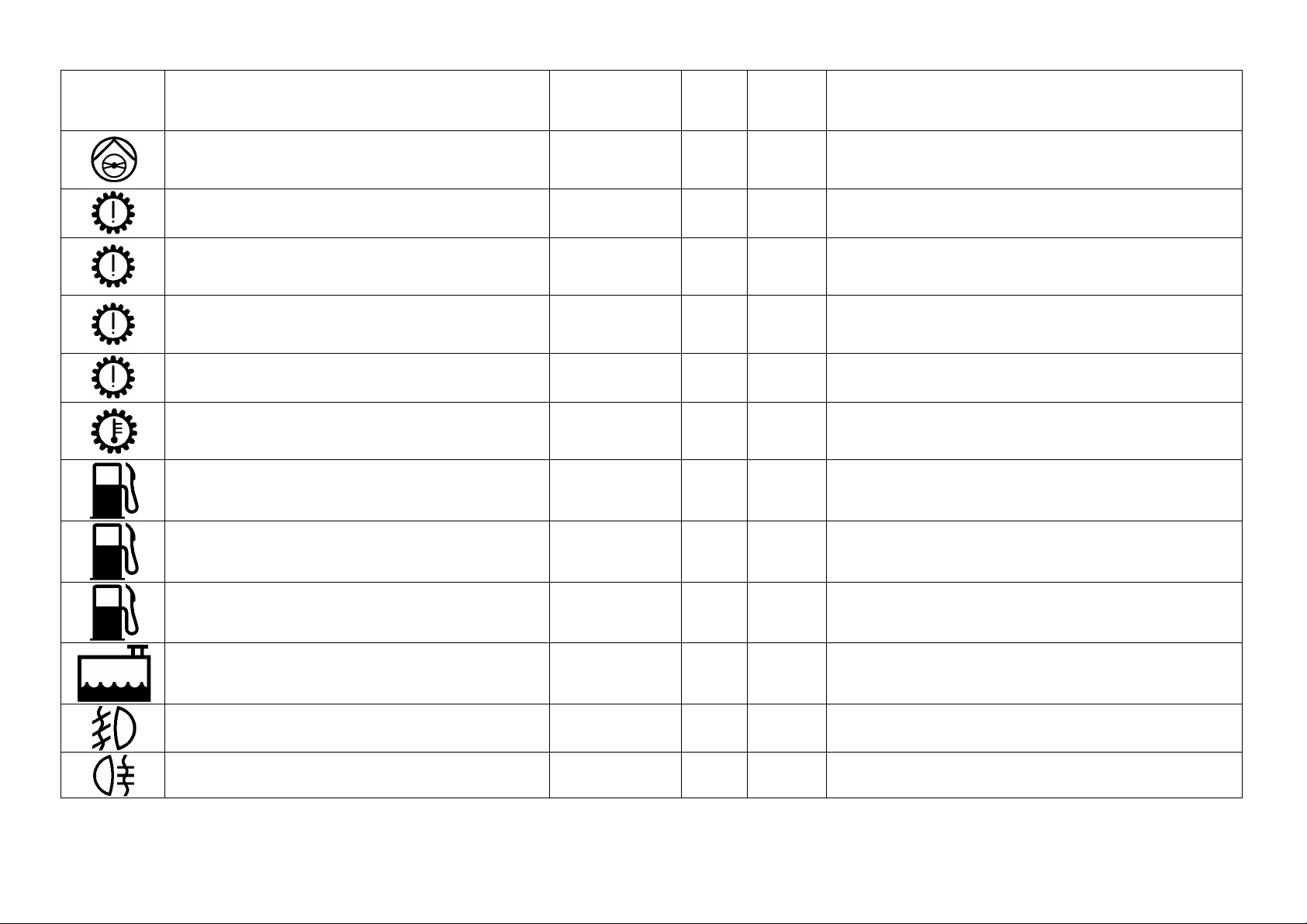

|

ТЕКСТ СООБЩЕНИЯ(КРАТКАЯ ФОРМА – БК) |

ТЕКСТ НА ЦЕНТРАЛЬНОМ ИНФОРМАЦИОННОМ ДИСПЛЕЕ(ДЛИННАЯ ФОРМА, НА МОНИТОРЕ CCC ИЛИ CIC) |

|

NO FAULTS (ВСЕ В ПОРЯДКЕ) |

|

|

ACC DEACTIVATED! (ACC ОТКЛЮЧИЛСЯ!) DRIVE WITH CARE (НЕ РАЗГОНЯЙТЕСЬ) |

ACC DEACTIVATED (ACC ОТКЛЮЧИЛСЯ) ACTIVE CRUISE CONTROL ACC DEACTIVATED DUE TO RISK OF SKIDDING. (АКТИВНЫЙ КРУИЗ-КОНТРОЛЬ ВЫКЛЮЧЕН ИЗ-ЗА СКОЛЬЗКОЙ ДОРОГИ.) KEEP YOUR DISTANCE AND DRIVE WITH CARE! (НЕ РАЗГОНЯЙТЕСЬ И СОБЛЮДАЙТЕ ДИСТАНЦИЮ) REACTIVATE ACC AS NEEDED WHEN DRIVING SITUATION ALLOWS. (ВКЛЮЧИТЕ ACC СНОВА, КОГДА ПОЗВОЛЯТ УСЛОВИЯ.) |

|

ACC DEACTIVATED! (ACC ОТКЛЮЧИЛСЯ!) KEEP YOUR DISTANCE (СОБЛЮДАЙТЕ ДИСТАНЦИЮ) |

ACC DEACTIVATED (ACC ОТКЛЮЧИЛСЯ) ACTIVE CRUISE CONTROL ACC DEACTIVATED DUE TO DIRTY SENSOR. (АКТИВНЫЙ КРУИЗ-КОНТРОЛЬ ВЫКЛЮЧЕН ИЗ-ЗА ЗАГРЯЗНЕНИЯ ДАТЧИКА) KEEP YOUR DISTANCE! (СОБЛЮДАЙТЕ ДИСТАНЦИЮ!) WIPE SENSOR CLEAN, SEE OWNER’S HANDBOOK. (ПРОТРИТЕ ДАТЧИК, СМ. РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ) |

|

ACC DEACTIVATED! (ACC ОТКЛЮЧИЛСЯ!) KEEP YOUR DISTANCE (СОБЛЮДАЙТЕ ДИСТАНЦИЮ) |

ACC FAILURE (ОТКАЗ ACC) ACTIVE CRUISE CONTROL ACC FAILURE (ОТКАЗ ACC) KEEP YOUR DISTANCE! (СОБЛЮДАЙТЕ ДИСТАНЦИЮ!) PLEASE CONSULT BMW SERVICE. (ОБРАТИТЕСЬ НА СТОА BMW) |

|

TRAILER, PARKING LIGHT, LEFT! (ПРИЦЕП, ЛЕВ.СТОЯНОЧНЫЙ!) CHECK (ПРОВЕРЬТЕ) |

|

|

TRAILER, PARKING LIGHT, RIGHT! (ПРИЦЕП, ПРАВ.СТОЯНОЧНЫЙ!) CHECK (ПРОВЕРЬТЕ) |

|

|

TRAILER, INDICATOR, LEFT! (ПРИЦЕП, ЛЕВ.ПОВОРОТНИК!) CHECK (ПРОВЕРЬТЕ) |

|

|

TRAILER, INDICATOR, RIGHT! (ПРИЦЕП, ПРАВ.ПОВОРОТНИК!) CHECK (ПРОВЕРЬТЕ) |

|

|

TRAILER, BRAKE LIGHTS! (ПРИЦЕП, СТОП-СИГНАЛЫ!) CHECK (ПРОВЕРЬТЕ) |

|

|

TRAILER, FOG LIGHT! (ПРИЦЕП, П/ТУМАННЫЙ!) CHECK (ПРОВЕРЬТЕ) |

|

|

RADIO-CONTROL KEY IN LOCK! (КЛЮЧ В ЗАМКЕ!) |

|

|

DOOR OPEN! (ОТКРЫТА ДВЕРЬ) (= FRONT RIGHT) (= ПРАВАЯ ПЕРЕДНЯЯ) |

|

|

DOOR OPEN! (ОТКРЫТА ДВЕРЬ) (= FRONT LEFT) (= ЛЕВАЯ ПЕРЕДНЯЯ) |

|

|

DOOR OPEN! (ОТКРЫТА ДВЕРЬ) (= REAR LEFT) (= ЛЕВАЯ ЗАДНЯЯ) |

|

|

DOOR OPEN! (ОТКРЫТА ДВЕРЬ) (= REAR RIGHT) (= ПРАВАЯ ЗАДНЯЯ) |

|

|

BONNET OPEN! (ОТКРЫТ КАПОТ!) STOP THE VEHICLE CAREFULLY! (ОСТАНОВИТЕСЬ!) |

OPEN THE ENGINE HOOD (ОТКРЫТ КАПОТ!) ENGINE HOOD IS NOT LOCKED. (КАПОТ НЕ ЗАПЕРТ.) RISK OF ACCIDENT! (РИСК АВАРИИ) STOP VEHICLE AND CLOSE HOOD. (ОСТАНОВИТЕСЬ И ЗАКРОЙТЕ КАПОТ.) |

|

BOOT OPEN! (ОТКРЫТ БАГАЖНИК!) |

|

|

IGNITION FAULTY! (ЗАЖИГАНИЕ НЕИСПРАВНО!) |

IGNITION MALFUNCTION (ЗАЖИГАНИЕ НЕИСПРАВНО!) ENGINE CAN POSSIBLY ONLY BE STARTED WITH THE BRAKE PEDAL DEPRESSED. (ДВИГАТЕЛЬ МОЖЕТ БЫТЬ ЗАПУЩЕН ТОЛЬКО ПРИ НАЖАТОЙ ПЕДАЛИ ТОРМОЗА) CONTACT THE NEAREST BMW SERVICE. (СВЯЖИТЕСЬ С БЛИЖАЙШЕЙ СТОА BMW) |

|

STARTER MOTOR! (СТАРТЕР!) DO NOT STOP ENGINE (НЕ ВЫКЛЮЧАЙТЕ ДВИГАТЕЛЬ!) |

STARTER MOTOR DEFECTIVE (СТАРТЕР НЕИСПРАВЕН) NOT POSSIBLE TO RESTART THE ENGINE. (ПОВТОРНЫЙ ПУСК ДВИГАТЕЛЯ НЕВОЗМОЖЕН) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

DBC FAILURE! (ОТКАЗ DBC!) DRIVE WITH CARE (НЕ РАЗГОНЯЙТЕСЬ) |

DBC FAILURE (ОТКАЗ DBC) NO ADDITIONAL BRAKE SUPPORT FROM DBC WHEN EMERGENCY BRAKING. (ПРИ ЭКСТРЕННОМ ТОРМОЖЕНИИ ОТСУТСТВУЕТ ПОДДЕРЖКА СО СТОРОНЫ DBC) DRIVE WITH CARE (НЕ РАЗГОНЯЙТЕСЬ) HAVE THE PROBLEM CHECKED BY BMW SERVICE AS SOON AS POSSIBLE. (КАК МОЖНО СКОРЕЕ ОБРАТИТЕСЬ НА СТОА BMW) |

|

PREHEATING! (РАЗОГРЕВ!) PLEASE WAIT (ЖДИТЕ) |

|

|

CRUISE CONTROL FAILURE. (АКТИВНЫЙ КРУИЗ-КОНТРОЛЬ НЕ РАБОТАЕТ) |

CRUISE CONTROL (КРУИЗ-КОНТРОЛЬ) CRUISE CONTROL FAILURE. (АКТИВНЫЙ КРУИЗ-КОНТРОЛЬ НЕ РАБОТАЕТ) POSSIBLE TO CONTINUE JOURNEY WITH CAUTION. (ДАЛЬНЕЙШЕЕ ДВИЖЕНИЕ ВОЗМОЖНО) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

ENGINE OIL LEVEL! (УРОВЕНЬ МАСЛА В ДВИГАТЕЛЕ!) TOP UP ENGINE OIL! (ДОЛЕЙТЕ МАСЛО!) |

ENGINE OIL LEVEL (УРОВЕНЬ МАСЛА) ENGINE OIL LEVEL AT MINIMUM: (МАСЛО В ДВИГАТЕЛЕ НА МИНИМУМЕ.) ADD 1 LITRE OF ENGINE OIL AT THE NEXT OPPORTUNITY, PLEASE REFER TO THE OWNER’S HANDBOOK. (ПРИ БЛИЖАЙШЕЙ ВОЗМОЖНОСТИ ДОЛЕЙТЕ 1 ЛИТР МАСЛА, СМ. РУКОВОДСТВО) |

|

ENGINE OIL LEVEL! (УРОВЕНЬ МАСЛА В ДВИГАТЕЛЕ!) TOP UP ENGINE OIL! (ДОЛЕЙТЕ МАСЛО!) |

ENGINE OIL LEVEL (УРОВЕНЬ МАСЛА) BELOW MINIMUM. (НИЖЕ МИНИМУМА.) ADD 1 LITRE OF ENGINE OIL AT THE NEXT OPPORTUNITY, PLEASE REFER TO THE OWNER’S HANDBOOK. (ПРИ БЛИЖАЙШЕЙ ВОЗМОЖНОСТИ ДОЛЕЙТЕ 1 ЛИТР МАСЛА, СМ. РУКОВОДСТВО) |

|

ENGINE FAULT! (ДВИГАТЕЛЬ!) REDUCED POWER (ПАДЕНИЕ МОЩНОСТИ) |

ENGINE MALFUNCTION (НЕПОЛАДКИ В ДВИГАТЕЛЕ) FULL ENGINE OUTPUT NO LONGER AVAILABLE. (ДВИГАТЕЛЬ НЕ РАЗВИВАЕТ ПОЛНУЮ МОЩНОСТЬ) DRIVE WITH CARE. (НЕ РАЗГОНЯЙТЕСЬ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

ENGINE! (ДВИГАТЕЛЬ!) STOP THE VEHICLE CAREFULLY! (ОСТАНОВИТЕСЬ!) |

ENGINE MALFUNCTION (НЕПОЛАДКИ В ДВИГАТЕЛЕ) DRIVING ON COULD CAUSE ENGINE DAMAGE. (УГРОЗА ПОВРЕЖДЕНИЯ ДВИГАТЕЛЯ.) STOP THE VEHICLE AND SWITCH OFF THE ENGINE. (ОСТАНОВИТЕСЬ И ЗАГЛУШИТЕ ДВИГАТЕЛЬ.) CONTACT THE NEAREST BMW SERVICE. (СВЯЖИТЕСЬ С БЛИЖАЙШЕЙ СТОА BMW) |

|

INCREASED EMISSIONS! (ТОКСИЧНЫЙ ВЫХЛОП) |

INCREASED EMISSIONS (ТОКСИЧНЫЙ ВЫХЛОП) ENGINE MALFUNCTION INFLUENCING EXHAUST EMISSIONS. (НЕПОЛАДКИ В ДВИГАТЕЛЕ, ВЛИЯЮЩИЕ НА СОСТАВ ОГ. ) HAVE THE PROBLEM CHECKED BY BMW SERVICE AS SOON AS POSSIBLE. (КАК МОЖНО СКОРЕЕ ОБРАТИТЕСЬ НА СТОА BMW) |

|

PLEASE CLOSE FILTER CAP! (ТОПЛИВНЫЙ БАК ОТКРЫТ!) |

FUEL FILLER CAP OPEN! (ТОПЛИВНЫЙ БАК ОТКРЫТ) FUEL OR FUEL VAPOURS COULD ESCAPE. (ОПАСНОСТЬ ВЫБРОСА ТОПЛИВА ИЛИ ЕГО ПАРОВ.) CHECK THAT FUEL FILLER CAP IS PROPERLY CLOSED AND ENGAGED. (ПРОВЕРЬТЕ КРЫШКУ ТОПЛИВНОГО БАКА) |

|

ENGINE FAULT! (ДВИГАТЕЛЬ!) DRIVE WITH CARE (НЕ РАЗГОНЯЙТЕСЬ) |

ENGINE MALFUNCTION (НЕПОЛАДКИ В ДВИГАТЕЛЕ) INCREASED ENGINE LOAD COULD DAMAGE THE CATALYTIC CONVERTER. (ПОВЫШЕННАЯ НАГРУЗКА НА ДВИГАТЕЛЬ ВРЕДИТ КАТАЛИЗАТОРУ.) DRIVE WITH MODERATE ENGINE LOAD. (УМЕНЬШИТЕ НАГРУЗКУ НА ДВИГАТЕЛЬ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

DSC FAILURE! (ОТКАЗ DSC) DRIVE WITH CARE (НЕ РАЗГОНЯЙТЕСЬ) |

DSC FAILURE (ОТКАЗ DSC) DRIVING STABILITY RESTRICTED WHEN ACCELERATING AND CORNERING. (СНИЖЕНА УСТОЙЧИВОСТЬ В ПОВОРОТАХ И ПРИ РАЗГОНЕ) DRIVE WITH CARE (НЕ РАЗГОНЯЙТЕСЬ) HAVE THE PROBLEM CHECKED BY BMW SERVICE AS SOON AS POSSIBLE. (КАК МОЖНО СКОРЕЕ ОБРАТИТЕСЬ НА СТОА BMW) |

|

DSC DEACTIVATED! (DSC ВЫКЛЮЧЕНА!) |

DSC DEACTIVATED (DSC ВЫКЛЮЧЕНА) DSC DEACTIVATED. (ВЫ ВЫКЛЮЧИЛИ СИСТЕМУ DSC) DRIVING STABILITY RESTRICTED WHEN ACCELERATING AND CORNERING. (СНИЖЕНА УСТОЙЧИВОСТЬ В ПОВОРОТАХ И ПРИ РАЗГОНЕ) |

|

REMOTE CONTROL! UNIDENTIFIED KEY (КЛЮЧ! НЕИДЕНТИФИЦИРОВАННЫЙ КЛЮЧ) |

REMOTE CONTROL (КЛЮЧ) THE REMOTE CONTROL USED IS NOT ASSIGNED TO THIS VEHICLE. (ИСПОЛЬЗУЕМЫЙ КЛЮЧ НЕ ПОДХОДИТ.) PLEASE CHECK. (ПРОВЕРЬТЕ КЛЮЧ.) |

|

ENGINE OVERHEATED! (ДВИГАТЕЛЬ ПЕРЕГРЕЛСЯ!) STOP THE VEHICLE CAREFULLY (ОСТАНОВИТЕСЬ) |

ENGINE OVERHEATING (ДВИГАТЕЛЬ ПЕРЕГРЕЛСЯ) STOP THE ENGINE AND ALLOW IT TO COOL. (ЗАГЛУШИТЕ ДВИГАТЕЛЬ И ДАЙТЕ ЕМУ ОСТЫТЬ) DO NOT OPEN ENGINE HOOD, RISK OF SCOLDING! (КАПОТ НЕ ОТКРЫВАЙТЕ.) RISK OF SCALDING! (КАПОТ НЕ ОТКРЫВАЙТЕ. ОПАСНОСТЬ ОЖОГА!) CONTACT THE NEAREST BMW SERVICE. (СВЯЖИТЕСЬ С БЛИЖАЙШЕЙ СТОА BMW) |

|

TO START ENGINE, PRESS BRAKE PEDAL (ДЛЯ ЗАПУСКА ДВИГАТЕЛЯ НАЖМИТЕ НА ПЕДАЛЬ ТОРМОЗА) |

|

|

SERVICE DUE! (НАСТУПИЛ СРОК ТО!) |

SERVICE DUE (НАСТУПИЛ СРОК ТО) YOUR BMW DEALER WAS UNABLE TO BE INFORMED AUTOMATICALLY. (ВАША СТОА НЕ БЫЛА АВТОМАТИЧЕСКИ ПРОИНФОРМИРОВАНА ОБ ЭТОМ.) PLEASE CONTACT YOUR BMW SERVICE. (СВЯЖИТЕСЬ СО СВОЕЙ СТОА BMW) |

|

CONTROL SYSTEMS! (СИСТЕМЫ РЕГУЛИРОВКИ) DRIVE WITH CARE (НЕ РАЗГОНЯЙТЕСЬ) |

CONTROL SYSTEMS (СИСТЕМЫ РЕГУЛИРОВКИ) GROUND CLEARANCE / DRIVING COMFORT REDUCED. (КЛИРЕНС/КОМФОРТ МЕНЬШЕ ОБЫЧНОГО.) AVOID HIGH SPEEDS WHEN CORNERING. (СКОРОСТЬ В ПОВОРОТАХ ДОЛЖНА БЫТЬ УМЕРЕННОЙ.) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (КАК МОЖНО СКОРЕЕ ОБРАТИТЕСЬ НА СТОА BMW) |

|

FASTEN SEAT BELT (ПРИСТЕГНИТЕСЬ) |

|

|

PARTICULATE FILTER MALFUNCTION (САЖЕВЫЙ ФИЛЬТР ТРЕБУЕТ ОБСЛУЖИВАНИЯ) |

PARTICULATE FILTER MALFUNCTION (САЖЕВЫЙ ФИЛЬТР ТРЕБУЕТ ОБСЛУЖИВАНИЯ) POSSIBLE TO CONTINUE JOURNEY WITH CAUTION. (ДАЛЬНЕЙШЕЕ ДВИЖЕНИЕ ВОЗМОЖНО) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

RUN FLAT INDICATOR FAILURE! (ОТКАЗ ИНДИКАТОРА ПОВРЕЖДЕНИЯ ШИН!) |

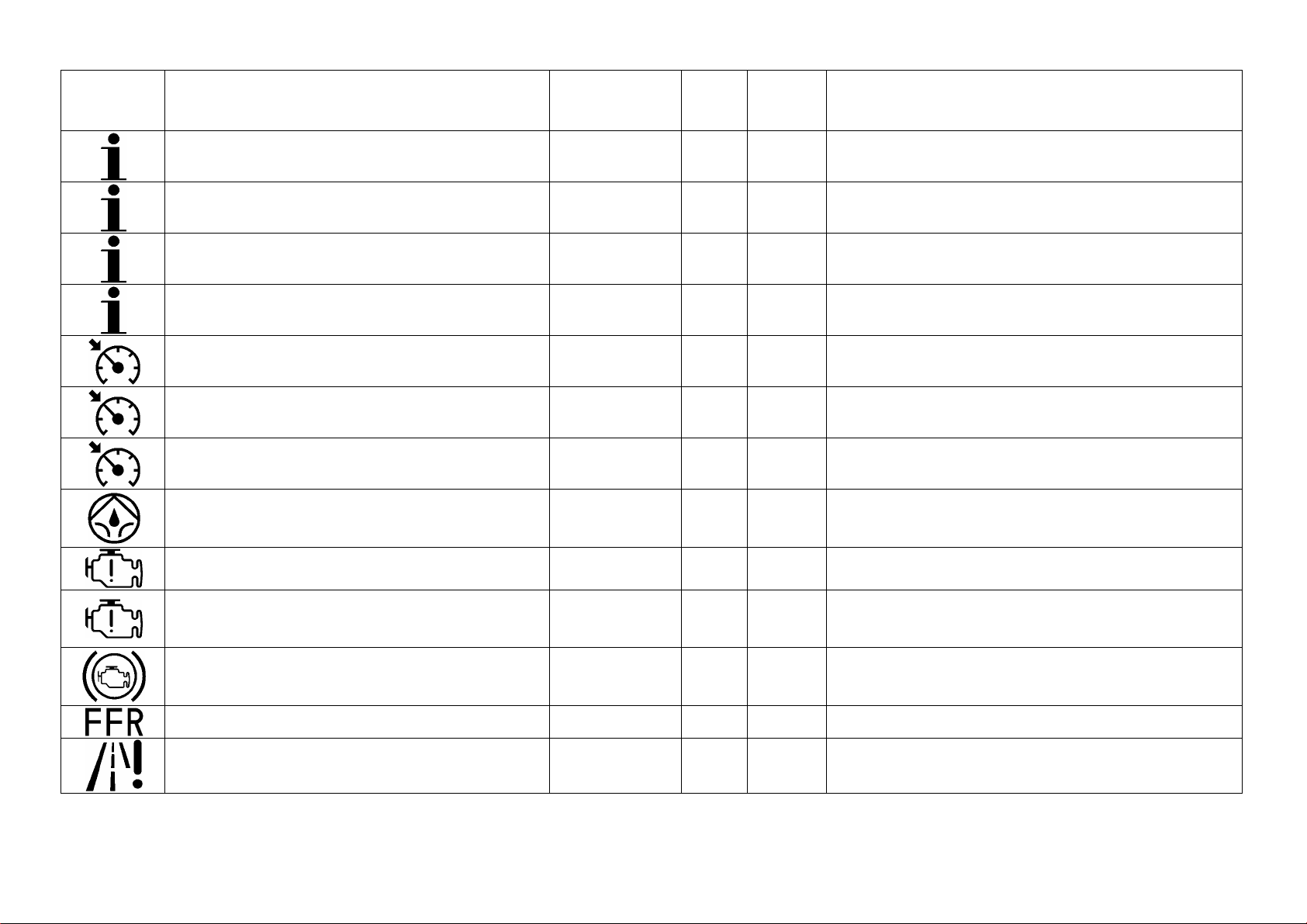

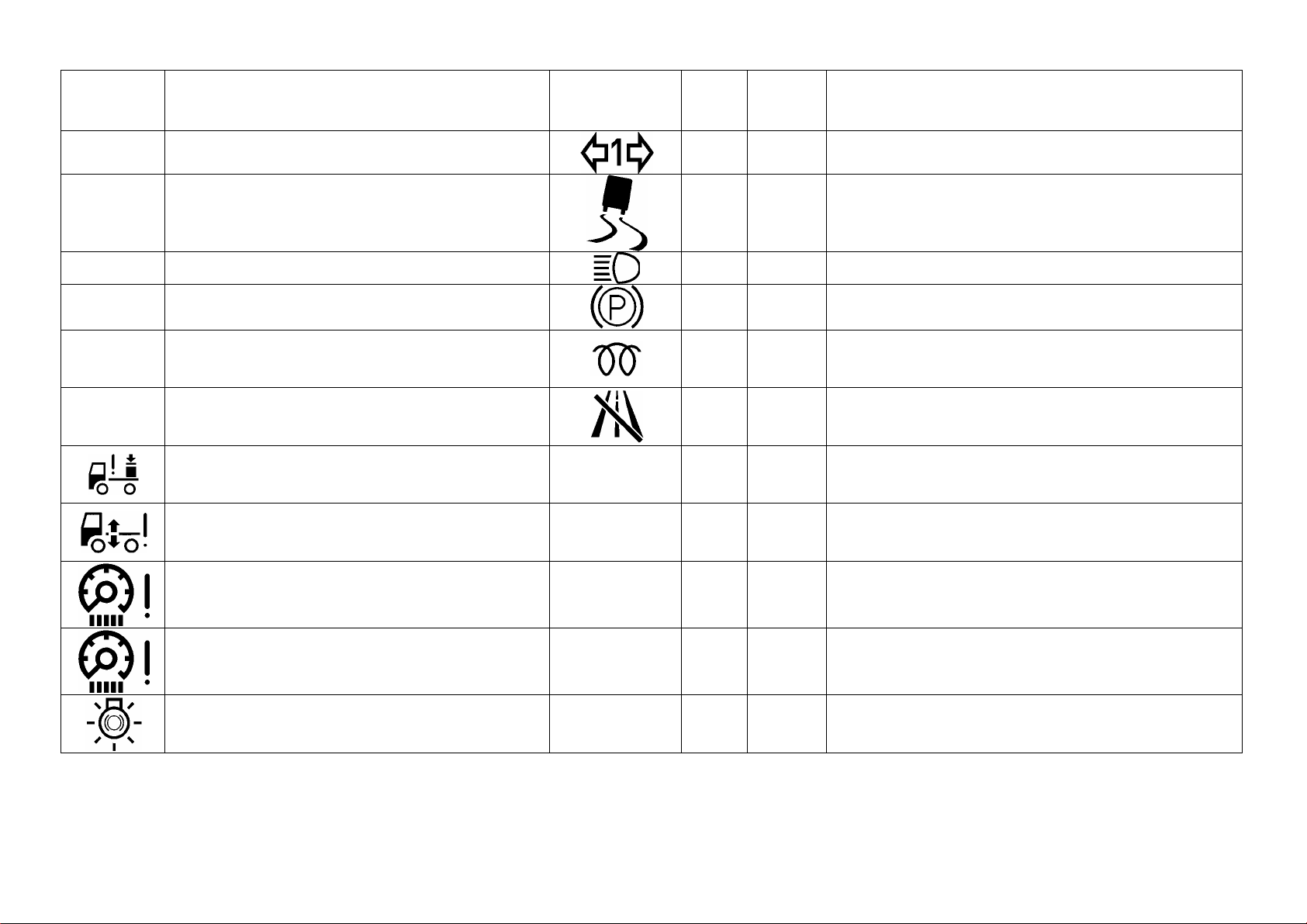

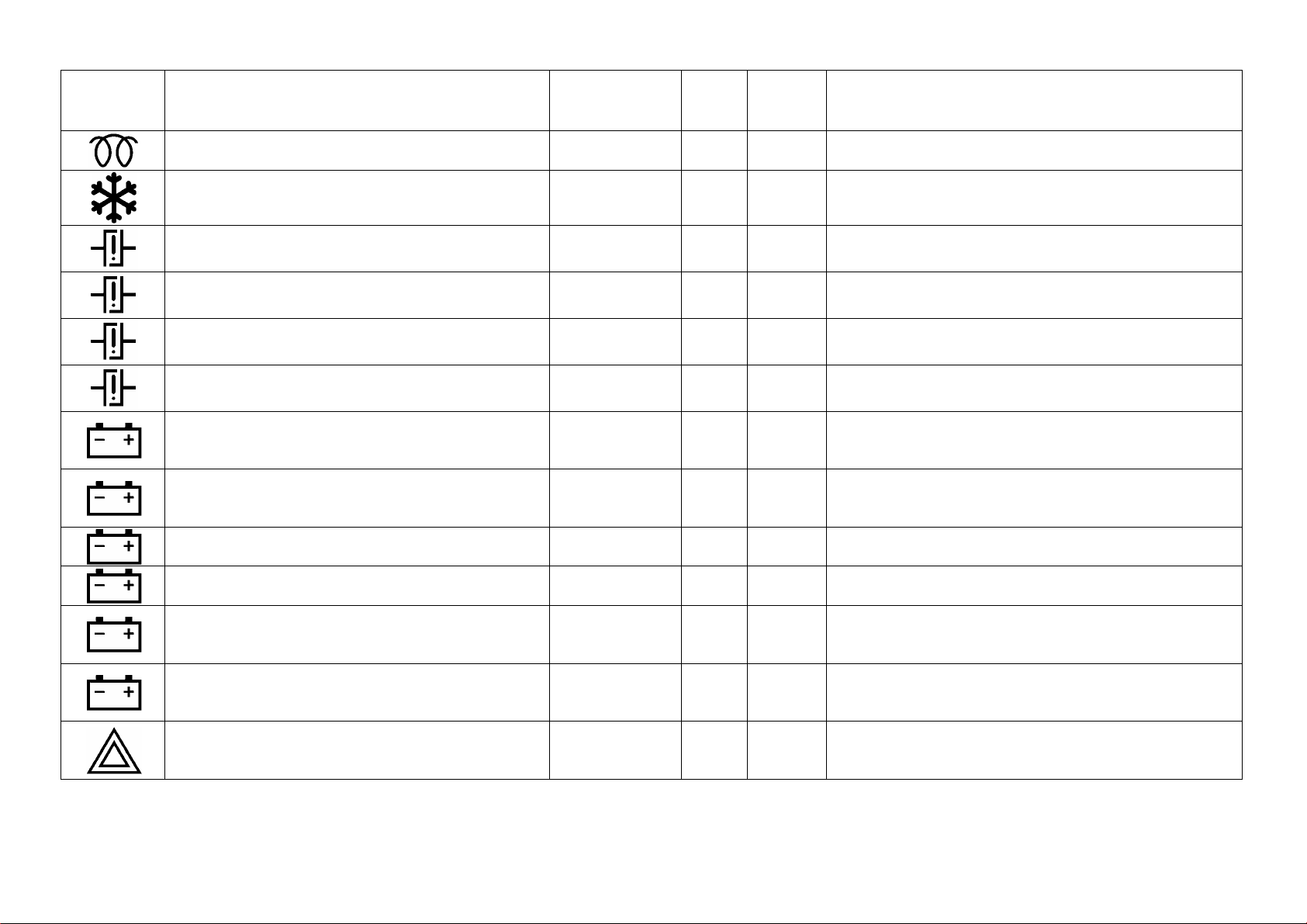

RUN FLAT INDICATOR (ИНДИКАТОР ПОВРЕЖДЕНИЯ ШИН) RUN FLAT INDICATOR FAILED. (ОТКАЗ ИНДИКАТОРА ПОВРЕЖДЕНИЯ ШИН.) FLAT TYRES CANNOT BE DETECTED. (ПОВРЕЖДЕНИЯ ШИН НЕ РАСПОЗНАЮТСЯ) HAVE THE PROBLEM CHECKED BY BMW SERVICE AS SOON AS POSSIBLE. (КАК МОЖНО СКОРЕЕ ОБРАТИТЕСЬ НА СТОА BMW) |

|

SPEEDOMETER DISPLAY FAULT! (СПИДОМЕТР НЕИСПРАВЕН) |

SPEEDOMETER DISPLAY (СПИДОМЕТР) SPEEDOMETER DISPLAY MALFUNCTION. (СПИДОМЕТР НЕИСПРАВЕН) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

SPEED LIMIT EXCEEDED! (ПРЕВЫШЕН ПРЕДЕЛ СКОРОСТИ) (= ТОЛЬКО ДЛЯ СТРАН ПЕРСИДСКОГО ЗАЛИВА) |

|

|

LOSS OF TYRE PRESSURE! (ПОТЕРЯ ДАВЛЕНИЯ В ШИНАХ!) |

LOSS OF TYRE PRESSURE (ПОТЕРЯ ДАВЛЕНИЯ В ШИНАХ) STOP THE VEHICLE CAREFULLY. (ОСТАНОВИТЕСЬ) IF TYRES WITH RUNFLAT CHARACTERISTICS (“RSC” SYMBOL) ARE FITTED, IT IS POSSIBLE TO CONTINUE THE JOURNEY AT SPEEDS UP TO 80 KM/H. (ПРИ НАЛИЧИИ ШИН, ДОПУСКАЮЩИХ ДВИЖЕНИЕ В АВАРИЙНОМ РЕЖИМЕ (СИМВОЛ “RSC”), МОЖНО ПРОДОЛЖИТЬ ДВИЖЕНИЕ СО СКОРОСТЬЮ НЕ БОЛЕЕ 80 КМ/Ч.) PLEASE REFER TO THE OWNER’S HANDBOOK FOR IMPORTANT INFORMATION. (ВАЖНУЮ ИНФОРМАЦИЮ СМ. В РУКОВОДСТВЕ ПО ЭКСПЛУАТАЦИИ.) NOTE: (УКАЗАНИЕ:) THE CAUSE MAY BE THE TYRE PRESSURE SETTING. (ПРИЧИНОЙ МОЖЕТ БЫТЬ ТАКЖЕ РЕГУЛИРОВКА ДАВЛЕНИЯ В ШИНАХ.) |

|

CHARGE BATTERY IN KEY / REMOTE CONTROL! (АККУМУЛЯТОР В КЛЮЧЕ!) CHARGING (ЗАРЯДИТЕ) |

KEY / REMOTE CONTROL (КЛЮЧ/БЛОК ДУ) THE BATTERY IS AUTOMATICALLY RECHARGED DURING LENGTHY JOURNEYS WITH THE KEY IN THE IGNITION LOCK. (АККУМУЛЯТОР КЛЮЧА ЗАРЯЖАЕТСЯ В ЗАМКЕ ЗАЖИГАНИЯ ВО ВРЕМЯ ДВИЖЕНИЯ) |

|

REMOTE CONTROL! (КЛЮЧ!) NO ENGINE START (ПУСК ДВИГАТЕЛЯ НЕВОЗМОЖЕН) |

REMOTE CONTROL (КЛЮЧ) REMOTE CONTROL NOT AVAILABLE OR FAULTY. (КЛЮЧ ОТСУТСТВУЕТ ИЛИ НЕИСПРАВЕН) ENGINE START NOT POSSIBLE. (ЗАПУСК ДВИГАТЕЛЯ НЕВОЗМОЖЕН) PLEASE REFER TO THE OWNER’S HANDBOOK. (СМ. РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ) |

|

REMOTE CONTROL BATTERY DISCHARGED! (РАЗРЯЖЕНА БАТАРЕЙКА В КЛЮЧЕ!) |

REMOTE CONTROL (КЛЮЧ) BATTERIES IN “REMOTE CONTROL WITH INTEGRATED KEY” FLAT. (ЭЛЕМЕНТ ПИТАНИЯ В КЛЮЧЕ РАЗРЯЖЕН) REPLACE, PLEASE REFER TO THE OWNER’S HANDBOOK. (ЗАМЕНИТЕ БАТАРЕЙКУ, СМ. РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ) |

|

BATT. REMOTE CONT. FOR STAT. FUNCT.! (БАТАРЕЙКА ДУ АВТОНОМНЫХ СИСТЕМ) |

REMOTE CONTROL (КЛЮЧ) BATTERIES OF “REMOTE CONTROL FOR STATIONARY FUNCTIONS” FLAT. (ЭЛЕМЕНТЫ ПИТАНИЯ В ПУЛЬТЕ ДУ АВТОНОМНЫМИ СИСТЕМАМИ СЕЛИ) REPLACE, PLEASE REFER TO THE OWNER’S HANDBOOK. (ЗАМЕНИТЕ БАТАРЕЙКУ, СМ. РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ) |

|

ACC DEACTIVATED! (ACC ОТКЛЮЧИЛСЯ!) KEEP YOUR DISTANCE (СОБЛЮДАЙТЕ ДИСТАНЦИЮ) |

ACC DEACTIVATED (ACC ОТКЛЮЧИЛСЯ) ACTIVE CRUISE CONTROL ACC DEACTIVATED UNDER APPROX. 30 KM/H (20 MPH). (АКТИВНЫЙ КРУИЗ-КОНТРОЛЬ ВЫКЛЮЧАЕТСЯ ПРИ СКОРОСТИ НИЖЕ 30 КМ/Ч) KEEP YOUR DISTANCE! (СОБЛЮДАЙТЕ ДИСТАНЦИЮ!) REACTIVATE ACC AS NEEDED. (ЕСЛИ НЕОБХОДИМО, ВКЛЮЧИТЕ ACC СНОВА) |

|

SERVOTRONIC FAILURE! (ОТКАЗ СЕРВОТРОНИКА) |

SERVOTRONIC FAILURE POSSIBLE TO CONTINUE JOURNEY WITH CAUTION. (ДАЛЬНЕЙШЕЕ ДВИЖЕНИЕ ВОЗМОЖНО) IMPORTANT: (ПРЕДУПРЕЖДЕНИЕ:) POWER-STEERING ASSISTANCE IS NO LONGER AUTOMATICALLY ADAPTED TO THE VEHICLE’S SPEED. (ВНИМАНИЕ: УСИЛИТЕЛЬ РУЛЯ НЕ ПОДСТРАИВАЕТСЯ К СКОРОСТИ ДВИЖЕНИЯ) HAVE THE PROBLEM CHECKED BY BMW SERVICE AS SOON AS POSSIBLE. (КАК МОЖНО СКОРЕЕ ОБРАТИТЕСЬ НА СТОА BMW) |

|

BRAKE PADS! (КОЛОДКИ!) REPLACE (ЗАМЕНИТЕ) |

BRAKE PADS (КОЛОДКИ) THE BRAKE PADS ARE WORN. (ИЗНОС ТОРМОЗНЫХ НАКЛАДОК) HAVE THEM REPLACED BY THE NEAREST BMW SERVICE. (ЗАМЕНИТЕ КОЛОДКИ НА БЛИЖАЙШЕЙ СТОА BMW) |

|

EPS INOPERABLE (EPS НЕ РАБОТАЕТ) (= БОРТОВОЙ КОМПЬЮТЕР) |

|

|

BRAKE FLUID! (ТОРМОЗНАЯ ЖИДКОСТЬ) STOP VEHICLE CAREFULLY (ОСТАНОВИТЕСЬ) |

BRAKE FLUID (ТОРМОЗНАЯ ЖИДКОСТЬ) INSUFFICIENT QUANTITY OF BRAKE FLUID. (НИЗКИЙ УРОВЕНЬ) BRAKING EFFECT REDUCED. (ЭФФЕКТИВНОСТЬ ТОРМОЗОВ СНИЖЕНА) STOP THE VEHICLE CAREFULLY. (ОСТАНОВИТЕСЬ) CONTACT THE NEAREST BMW SERVICE. (СВЯЖИТЕСЬ С БЛИЖАЙШЕЙ СТОА BMW) |

|

TRAILER TOW BAR ELECTRICS! (ОТКАЗ ЭЛЕКТРООБОРУДОВАНИЯ ПРИЦЕПА!) |

TRAILER ELECTRICS (ЭЛЕКТРИКА ПРИЦЕПА) TRAILER ELECTRICS FAILED. (ОТКАЗ ЭЛЕКТРООБОРУДОВАНИЯ ПРИЦЕПА) TRAILER LIGHTS AFFECTED. HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

SPEED LIMIT EXCEEDED! (ПРЕВЫШЕН ПРЕДЕЛ СКОРОСТИ) (= БОРТОВОЙ КОМПЬЮТЕР) |

|

|

OUTSIDE TEMPERATURE (ТЕМПЕРАТУРА НАРУЖНОГО ВОЗДУХА) (= ДЛЯ СЕВЕРНЫХ СТРАН) |

|

|

ACC DEACTIVATED! (ACC ОТКЛЮЧИЛСЯ!) MANUAL BRAKING (ТОРМОЗИТЕ САМИ) |

ACC DEACTIVATED (ACC ОТКЛЮЧИЛСЯ) ACTIVE CRUISE CONTROL ACC DEACTIVATED DUE TO LONG DOWNHILL DRIVE. (ACC ОТКЛЮЧИЛСЯ ИЗ-ЗА ЗАТЯЖНОГО СПУСКА) KEEP YOUR DISTANCE! (СОБЛЮДАЙТЕ ДИСТАНЦИЮ!) REACTIVATE ACC AS NEEDED. (ЕСЛИ НЕОБХОДИМО, ВКЛЮЧИТЕ ACC СНОВА) |

|

REAR LIGHT, RIGHT, FAILURE! (ПРАВЫЙ ЗАДНИЙ ФОНАРЬ НЕ РАБОТАЕТ!) |

REAR LAMPS (ЗАДНИЙ ФОНАРЬ) REAR RIGHT LAMP FAILED. (ПРАВЫЙ ЗАДНИЙ ФОНАРЬ НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

DIPPED BEAM, LEFT, FAILURE! (ЛЕВАЯ ФАРА БЛИЖНЕГО СВЕТА НЕ РАБОТАЕТ!) |

DIPPED-BEAM HEADLIGHTS (БЛИЖНИЙ СВЕТ) LEFT DIPPED-BEAM HEADLIGHT FAILED. (ЛЕВАЯ ФАРА БЛИЖНЕГО СВЕТА НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

DIPPED BEAM, RIGHT, FAILURE! (ПРАВАЯ ФАРА БЛИЖНЕГО СВЕТА НЕ РАБОТАЕТ!) |

DIPPED-BEAM HEADLIGHTS (БЛИЖНИЙ СВЕТ) RIGHT DIPPED-BEAM HEADLIGHTS FAILED. (ПРАВАЯ ФАРА БЛИЖНЕГО СВЕТА НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

TRAILER, REVERSING LIGHT! (ПРИЦЕП, ФОНАРИ ЗАДНЕГО ХОДА) |

|

|

FASTEN SEAT BELT (ПРИСТЕГНИТЕСЬ) |

|

|

FRONT PASS. RESTRAINT SYSTEM FAULTY! (РЕМЕНЬ ПАССАЖИРА НЕИСПРАВЕН!) |

PASSENGER SEAT BELT (РЕМЕНЬ ПАССАЖИРА) BELT TENSIONER OR BELT FORCE LIMITER MALFUNCTION. (НЕИСПРАВЕН ПРЕДНАТЯЖИТЕЛЬ ИЛИ ОГРАНИЧИТЕЛЬ УСИЛИЯ НАТЯЖЕНИЯ РЕМНЯ БЕЗОПАСНОСТИ) FASTEN SEAT BELT DESPITE MALFUNCTION! (ТЕМ НЕ МЕНЕЕ, ПРИСТЕГНИТЕСЬ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

DRIVER RESTRAINT SYSTEM FAULTY! (РЕМЕНЬ ВОДИТЕЛЯ НЕИСПРАВЕН) |

DRIVER’S SEAT BELT (РЕМЕНЬ ВОДИТЕЛЯ) BELT TENSIONER OR BELT FORCE LIMITER MALFUNCTION. (НЕИСПРАВЕН ПРЕДНАТЯЖИТЕЛЬ ИЛИ ОГРАНИЧИТЕЛЬ УСИЛИЯ НАТЯЖЕНИЯ РЕМНЯ БЕЗОПАСНОСТИ) FASTEN SEAT BELT DESPITE MALFUNCTION! (ТЕМ НЕ МЕНЕЕ, ПРИСТЕГНИТЕСЬ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

RESTRAINT SYSTEM, REAR LEFT, FAULTY! (ЛЕВЫЙ ЗАДНИЙ РЕМЕНЬ НЕИСПРАВЕН!) |

REAR LEFT SEAT BELT (ЛЕВЫЙ ЗАДНИЙ РЕМЕНЬ) BELT TENSIONER MALFUNCTION. (НЕИСПРАВЕН ПРЕДНАТЯЖИТЕЛЬ) FASTEN SEAT BELT DESPITE MALFUNCTION! (ТЕМ НЕ МЕНЕЕ, ПРИСТЕГНИТЕСЬ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

RESTRAINT SYSTEM, REAR RIGHT, FAULTY! (ПРАВЫЙ ЗАДНИЙ РЕМЕНЬ НЕИСПРАВЕН!) |

REAR RIGHT SEAT BELT (ПРАВЫЙ ЗАДНИЙ РЕМЕНЬ) BELT TENSIONER MALFUNCTION. (НЕИСПРАВЕН ПРЕДНАТЯЖИТЕЛЬ) FASTEN SEAT BELT DESPITE MALFUNCTION! (ТЕМ НЕ МЕНЕЕ, ПРИСТЕГНИТЕСЬ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

RESTRAINT SYSTEMS FAULTY! (СИСТЕМЫ БЕЗОПАСНОСТИ НЕИСПРАВНЫ!) |

RESTRAINT SYSTEMS (СИСТЕМЫ БЕЗОПАСНОСТИ) AIRBAGS, BELT TENSIONERS AND BELT FORCE LIMITERS MALFUNCTION. (НЕИСПРАВНОСТЬ НПБ, ПРЕДНАТЯЖИТЕЛЕЙ И ОГРАНИЧИТЕЛЕЙ УСИЛИЯ НАТЯЖЕНИЯ РЕМНЕЙ БЕЗОПАСНОСТИ) FASTEN BELTS DESPITE PROBLEM! (ТЕМ НЕ МЕНЕЕ, ПРИСТЕГНИТЕСЬ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

TRANSMISSION TOO HOT! (КПП ГРОЗИТ ПЕРЕГРЕВ!) |

TRANSMISSION TOO HOT (КПП НАГРЕВАЕТСЯ) POSSIBLE TO CONTINUE JOURNEY WITH CAUTION. (ДАЛЬНЕЙШЕЕ ДВИЖЕНИЕ ВОЗМОЖНО) ENGINE POWER OUTPUT REDUCED (МОЩНОСТЬ ДВИГАТЕЛЯ СНИЖЕНА) DRIVE WITH CARE (НЕ РАЗГОНЯЙТЕСЬ) |

|

TRANSMISSION FAULT! (ТЕМПЕРАТУРА КПП!) DRIVE WITH CARE (НЕ РАЗГОНЯЙТЕСЬ) |

TRANSMISSION TEMPERATURE RISK OF TRANSMISSION OVERHEATING. (ОПАСНОСТЬ ПЕРЕГРЕВА КПП) SHIFT PROGRAM WITH RESTRICTED DRIVING ACTIVE. (РАБОТАЕТ ОГРАНИЧИТЕЛЬНАЯ ПРОГРАММА) AVOID HIGH ENGINE LOADS. (ИЗБЕГАЙТЕ ВЫСОКОЙ НАГРУЗКИ НА ДВИГАТЕЛЬ) |

|

TRANSMISSION FAULT! (ТЕМПЕРАТУРА КПП!) STOP VEHICLE CAREFULLY (ОСТАНОВИТЕСЬ) |

TRANSMISSION OVERHEATING (КПП ПЕРЕГРЕЛАСЬ) STOP THE VEHICLE AND ENGAGE TRANSMISSION POSITION P. (ОСТАНОВИТЕСЬ И ВКЛЮЧИТЕ ПОЛОЖЕНИЕ P) ALLOW TO COOL AND CONTINUE JOURNEY WITH CARE. (ПОСЛЕ ОХЛАЖДЕНИЯ КПП НЕ РАЗГОНЯЙТЕСЬ) IN CASE OF REPEATED OVERHEATING, HAVE THE PROBLEM CHECKED BY YOUR BMW SERVICE. (ПРИ ПОВТОРНОМ ПЕРЕГРЕВЕ ОБРАТИТЕСЬ НА СТОА BMW) |

|

DRIVER AIRBAGS FAULTY! (НПБ ВОДИТЕЛЯ НЕИСПРАВНЫ!) |

DRIVER’S AIRBAGS (НПБ ВОДИТЕЛЯ) AIRBAGS MALFUNCTION. (ПОДУШКИ БЕЗОПАСНОСТИ НЕИСПРАВНЫ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

FRONT PASSENGER AIRBAGS FAULTY! (НПБ ПАССАЖИРА НЕИСПРАВНЫ!) |

FRONT-PASSENGER AIRBAGS (НПБ ПАССАЖИРА) AIRBAGS MALFUNCTION. (ПОДУШКИ БЕЗОПАСНОСТИ НЕИСПРАВНЫ) IF POSSIBLE, DO NOT OCCUPY THE FRONT-PASSENGER SEAT. (ПО ВОЗМОЖНОСТИ ДЕРЖИТЕ СИДЕНЬЕ ПЕРЕДНЕГО ПАССАЖИРА СВОБОДНЫМ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

NUMBER PLATE LIGHT LEFT, FAILURE! (ЛЕВАЯ ПОДСВЕТКА НОМЕРНОГО ЗНАКА НЕ РАБОТАЕТ!) |

LICENCE-PLATE LIGHT (ПОДСВЕТКА НОМ.ЗНАКА) LEFT LICENCE-PLATE LIGHT FAILED. (ОТКАЗ ЛЕВОГО ФОНАРЯ ПОДСВЕТКИ НОМЕРНОГО ЗНАКА) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

PARKING LIGHTS ON! (СТОЯНОЧНЫЕ ОГНИ ВКЛЮЧЕНЫ!) |

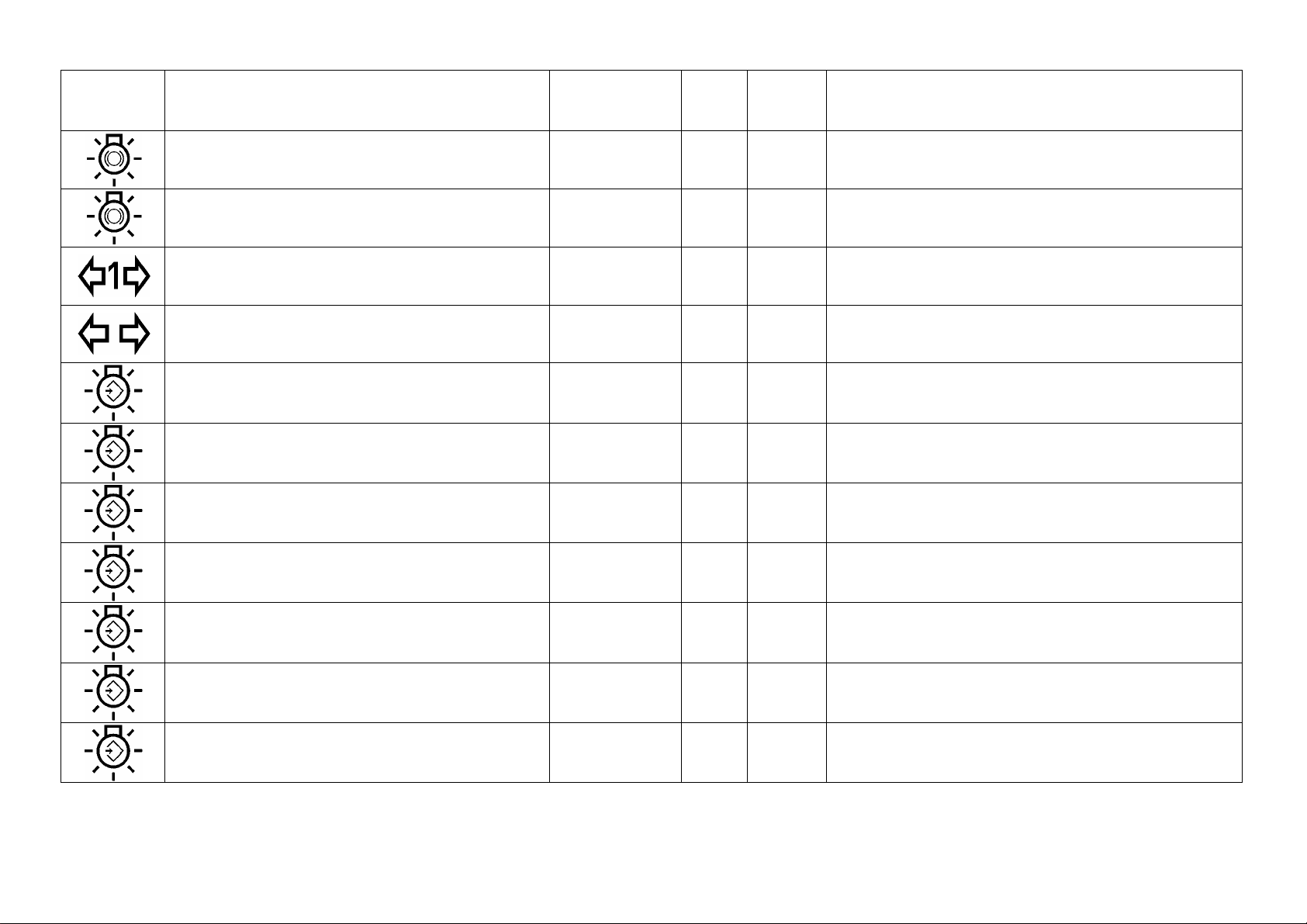

|

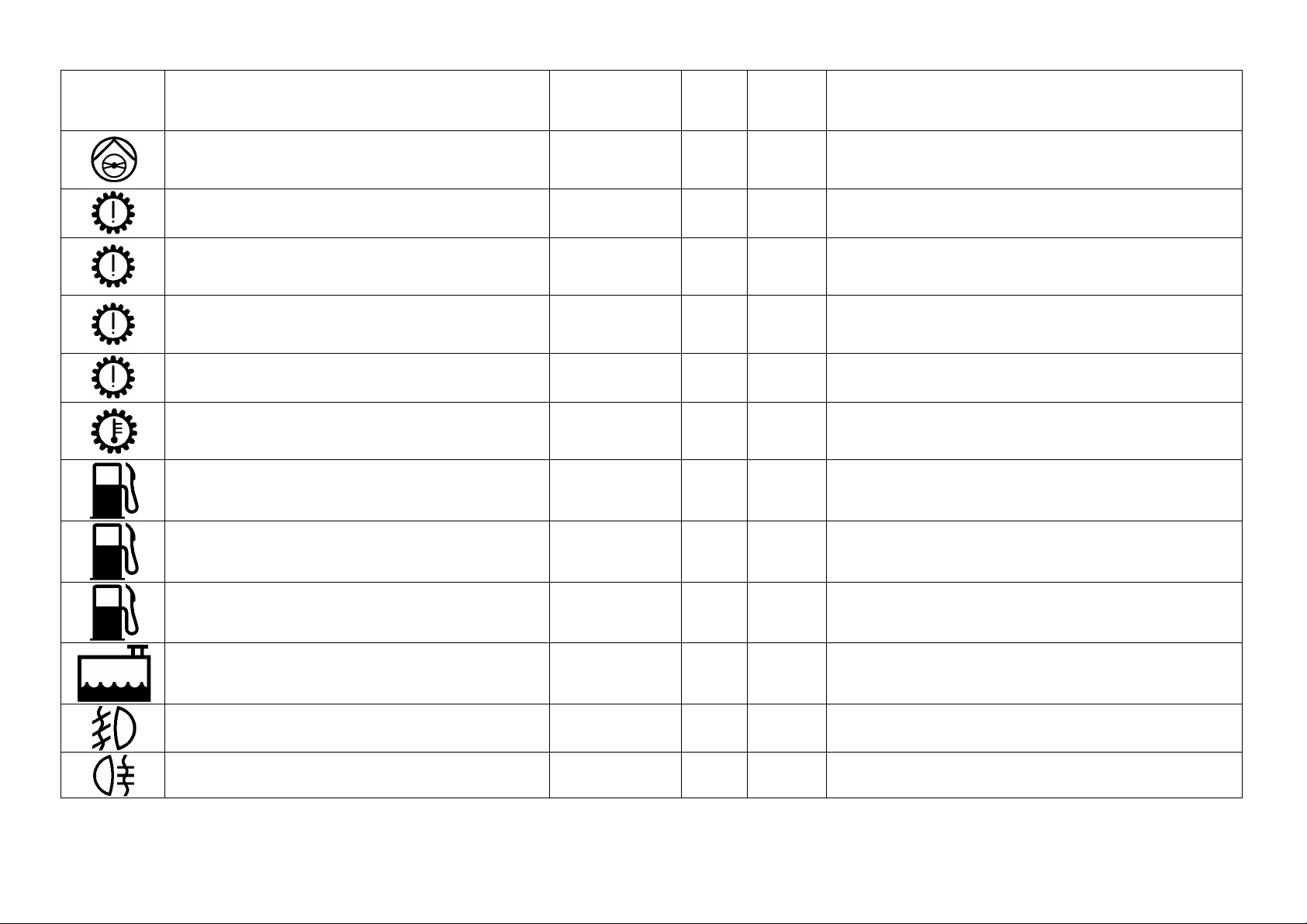

|

FOGLIGHT, REAR LEFT, FAILURE! (ЛЕВЫЙ ЗАДНИЙ ПРОТИВОТУМАННЫЙ НЕИСПРАВЕН) |

REAR FOGLIGHT (ПРОТИВОТУМАННЫЙ) REAR LEFT FOGLIGHT FAILED. (ЛЕВЫЙ ЗАДНИЙ ПРОТИВОТУМАННЫЙ ФОНАРЬ НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

REVERSING LIGHT, RIGHT, FAILURE! (ПРАВЫЙ ФОНАРЬ ЗАДНЕГО ХОДА НЕ РАБОТАЕТ!) |

REVERSING LIGHT (ФОНАРЬ ЗАДНЕГО ХОДА) RIGHT REVERSING LIGHT FAILED. (ПРАВЫЙ ФОНАРЬ ЗАДНЕГО ХОДА НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

INDICATOR, REAR LEFT, FAILURE! (ЛЕВЫЙ ЗАДНИЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) |

TURN SIGNAL LIGHTS (УКАЗАТЕЛЬ ПОВОРОТА) REAR LEFT TURN SIGNAL FAILED. (ЛЕВЫЙ ЗАДНИЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

REVERSING LIGHT, LEFT, FAILURE! (ЛЕВЫЙ ФОНАРЬ ЗАДНЕГО ХОДА НЕ РАБОТАЕТ!) |

REVERSING LIGHT (ФОНАРЬ ЗАДНЕГО ХОДА) LEFT REVERSING LIGHT FAILED. (ЛЕВЫЙ ФОНАРЬ ЗАДНЕГО ХОДА НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

REAR LIGHT, RIGHT, FAILURE! (ПРАВЫЙ ЗАДНИЙ ФОНАРЬ НЕ РАБОТАЕТ!) |

REAR LAMPS (ЗАДНИЙ ФОНАРЬ) REAR RIGHT LAMP FAILED. (ПРАВЫЙ ЗАДНИЙ ФОНАРЬ НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

INDICATOR, FRONT RIGHT, FAILURE! (ПРАВЫЙ ПЕРЕДНИЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) |

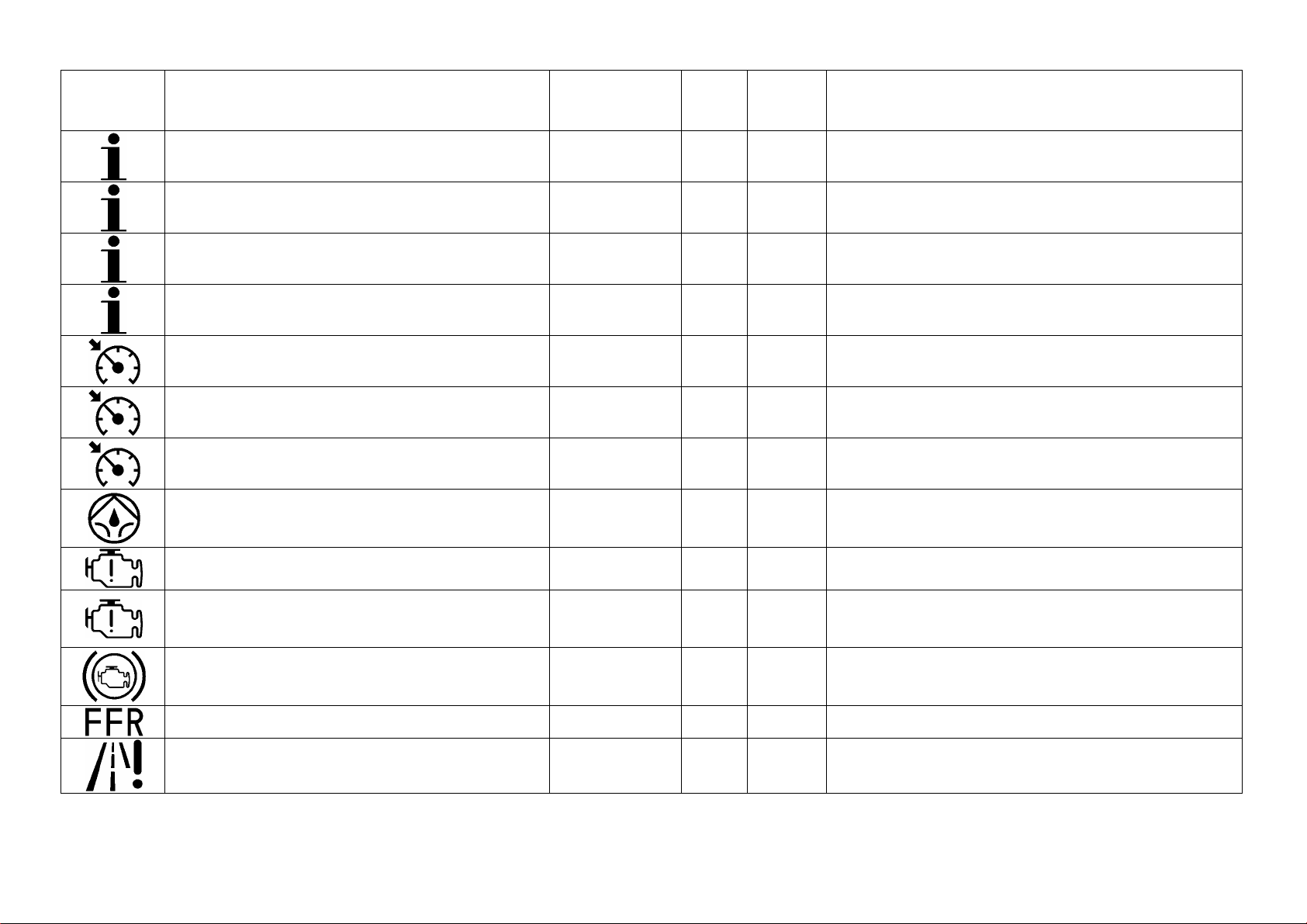

TURN SIGNAL LIGHTS (УКАЗАТЕЛЬ ПОВОРОТА) FRONT RIGHT TURN SIGNAL FAILED. (ПРАВЫЙ ПЕРЕДНИЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

DIPPED BEAM, LEFT, FAILURE! (ЛЕВАЯ ФАРА БЛИЖНЕГО СВЕТА НЕ РАБОТАЕТ!) |

DIPPED-BEAM HEADLIGHTS (БЛИЖНИЙ СВЕТ) LEFT DIPPED-BEAM HEADLIGHT FAILED. (ЛЕВАЯ ФАРА БЛИЖНЕГО СВЕТА НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

DIPPED BEAM, RIGHT, FAILURE! (ПРАВАЯ ФАРА БЛИЖНЕГО СВЕТА НЕ РАБОТАЕТ!) |

DIPPED-BEAM HEADLIGHTS (БЛИЖНИЙ СВЕТ) RIGHT DIPPED-BEAM HEADLIGHTS FAILED. (ПРАВАЯ ФАРА БЛИЖНЕГО СВЕТА НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

INDICATOR, FRONT LEFT, FAILURE! (ЛЕВЫЙ ПЕРЕДНИЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) |

TURN SIGNAL LIGHTS (УКАЗАТЕЛЬ ПОВОРОТА) FRONT LEFT TURN SIGNAL FAILED. (ЛЕВЫЙ ПЕРЕДНИЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

REAR LIGHT, LEFT, FAILURE! (ЛЕВЫЙ ЗАДНИЙ ФОНАРЬ НЕ РАБОТАЕТ!) |

REAR LAMPS (ЗАДНИЙ ФОНАРЬ) REAR LEFT LAMPS FAILED. (ЛЕВЫЙ ЗАДНИЙ ФОНАРЬ НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

SIDE INDICATOR, RIGHT, FAILURE! (ПРАВЫЙ БОКОВОЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) |

TURN SIGNAL LIGHTS (УКАЗАТЕЛЬ ПОВОРОТА) RIGHT SIDE-MOUNTED TURN SIGNAL FAILED. (ПРАВЫЙ БОКОВОЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

INDICATOR, REAR RIGHT, FAILURE! (ПРАВЫЙ ЗАДНИЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) |

TURN SIGNAL LIGHTS (УКАЗАТЕЛЬ ПОВОРОТА) REAR RIGHT TURN SIGNAL FAILED. (ПРАВЫЙ ЗАДНИЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

FOGLIGHT, FRONT RIGHT, FAILURE! (ПРАВАЯ ПРОТИВОТУМАННАЯ ФАРА НЕИСПРАВНА) |

FRONT FOGLIGHTS (ПРОТИВОТУМАННЫЕ ФАРЫ) FRONT RIGHT FOGLIGHT FAILED. (ПРАВАЯ ПРОТИВОТУМАННАЯ ФАРА НЕ РАБОТАЕТ) PLEASE CONSULT BMW SERVICE. (ОБРАТИТЕСЬ НА СТОА BMW) |

|

LEFT SIDE-MOUNTED TURN SIGNAL FAILED! (ЛЕВЫЙ БОКОВОЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) |

TURN SIGNAL LIGHTS (УКАЗАТЕЛЬ ПОВОРОТА) LEFT SIDE-MOUNTED TURN SIGNAL FAILED! (ЛЕВЫЙ БОКОВОЙ ПОВОРОТНИК НЕ РАБОТАЕТ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

FULL BEAM HEADLIGHT LEFT, FAILURE! (ЛЕВАЯ ФАРА ДАЛЬНЕГО СВЕТА НЕ РАБОТАЕТ!) |

MAIN-BEAM HEADLIGHTS (ДАЛЬНИЙ СВЕТ); LEFT MAIN-BEAM HEADLIGHT FAILED. (ЛЕВАЯ ФАРА ДАЛЬНЕГО СВЕТА НЕ РАБОТАЕТ) PLEASE CONSULT BMW SERVICE. (ОБРАТИТЕСЬ НА СТОА BMW) |

|

FOGLIGHT, REAR RIGHT, FAILURE! (ПРАВАЯ ПРОТИВОТУМАННАЯ ФАРА НЕИСПРАВНА!) |

REAR FOGLIGHT (ПРОТИВОТУМАННЫЙ) RIGHT REAR FOGLIGHT FAILED. (ПРАВЫЙ ЗАДНИЙ ПРОТИВОТУМАННЫЙ ФОНАРЬ НЕ РАБОТАЕТ) PLEASE CONSULT BMW SERVICE. (ОБРАТИТЕСЬ НА СТОА BMW) |

|

FULL BEAM HEADLIGHT RIGHT, FAILURE! (ПРАВАЯ ФАРА ДАЛЬНЕГО СВЕТА НЕ РАБОТАЕТ!) |

MAIN-BEAM HEADLIGHTS (ДАЛЬНИЙ СВЕТ); RIGHT MAIN-BEAM HEADLIGHT FAILED. (ПРАВАЯ ФАРА ДАЛЬНЕГО СВЕТА НЕ РАБОТАЕТ) PLEASE CONSULT BMW SERVICE. (ОБРАТИТЕСЬ НА СТОА BMW) |

|

PARKING LIGHT FRONT LEFT, FAILURE! (ЛЕВЫЙ ПЕРЕДНИЙ СТОЯНОЧНЫЙ НЕ РАБОТАЕТ!) |

PARKING LIGHTS (СТОЯНОЧНЫЕ ОГНИ) PARKING LIGHT FRONT LEFT, FAILURE! (ЛЕВЫЙ ПЕРЕДНИЙ СТОЯНОЧНЫЙ НЕ РАБОТАЕТ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

FRONT RIGHT SIDE LIGHT FAILED! (ПРАВЫЙ ПЕРЕДНИЙ СТОЯНОЧНЫЙ НЕ РАБОТАЕТ!) |

PARKING LIGHTS (СТОЯНОЧНЫЕ ОГНИ) FRONT RIGHT SIDE LIGHT FAILED! (ПРАВЫЙ ПЕРЕДНИЙ СТОЯНОЧНЫЙ НЕ РАБОТАЕТ!) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

REAR LIGHT, LEFT, FAILURE! (ЛЕВЫЙ ЗАДНИЙ ФОНАРЬ НЕ РАБОТАЕТ!) |

REAR LAMPS (ЗАДНИЙ ФОНАРЬ) REAR LEFT LAMPS FAILED. (ЛЕВЫЙ ЗАДНИЙ ФОНАРЬ НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

BRAKE LIGHT RIGHT, FAILURE! (ПРАВЫЙ СТОП-СИГНАЛ НЕ РАБОТАЕТ!) |

BRAKE LIGHTS (СТОП-СИГНАЛ) RIGHT BRAKE LIGHT FAILED. (ПРАВЫЙ СТОП-СИГНАЛ НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

THIRD BRAKE LIGHT, FAILURE! (ТРЕТИЙ СТОП-СИГНАЛ НЕ РАБОТАЕТ!) |

BRAKE LIGHTS (СТОП-СИГНАЛ) CENTRE BRAKE LIGHT FAILED. (ТРЕТИЙ СТОП-СИГНАЛ НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

BRAKE LIGHT LEFT, FAILURE! (ЛЕВЫЙ СТОП-СИГНАЛ НЕ РАБОТАЕТ!) |

BRAKE LIGHTS (СТОП-СИГНАЛ) LEFT BRAKE LIGHT FAILED. (ЛЕВЫЙ СТОП-СИГНАЛ НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

NUMBER PLATE LIGHT, RIGHT, FAILURE! (ПРАВ.ПОДСВЕТКА НОМЕРНОГО ЗНАКА НЕ РАБОТАЕТ!) |

LICENCE-PLATE LIGHT (ПОДСВЕТКА НОМ.ЗНАКА) RIGHT LICENCE-PLATE LIGHT FAILED. (ПРАВАЯ ПОДСВЕТКА НОМЕРНОГО ЗНАКА НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

FOGLIGHT, FRONT LEFT, FAILURE! (ЛЕВАЯ ПРОТИВОТУМАННАЯ ФАРА НЕИСПРАВНА!) |

FRONT FOGLIGHTS (ПРОТИВОТУМАННЫЕ ФАРЫ) FRONT LEFT FOGLIGHT FAILED. (ЛЕВАЯ ПРОТИВОТУМАННАЯ ФАРА НЕ РАБОТАЕТ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

LOSS OF TYRE PRESSURE FRONT LEFT! (ПОТЕРЯ ДАВЛЕНИЯ В ЛЕВОЙ ПЕРЕДНЕЙ ШИНЕ!) |

LOSS OF TYRE PRESSURE (ПОТЕРЯ ДАВЛЕНИЯ В ШИНАХ) STOP THE VEHICLE CAREFULLY. (ОСТАНОВИТЕСЬ) IF TYRES WITH RUNFLAT CHARACTERISTICS (“RSC” SYMBOL) ARE FITTED, IT IS POSSIBLE TO CONTINUE THE JOURNEY AT SPEEDS UP TO 80 KM/H. (ПРИ НАЛИЧИИ ШИН, ДОПУСКАЮЩИХ ДВИЖЕНИЕ В АВАРИЙНОМ РЕЖИМЕ (СИМВОЛ “RSC”), МОЖНО ПРОДОЛЖИТЬ ДВИЖЕНИЕ СО СКОРОСТЬЮ НЕ БОЛЕЕ 80 КМ/Ч.) PLEASE REFER TO THE OWNER’S HANDBOOK FOR IMPORTANT INFORMATION. (ВАЖНУЮ ИНФОРМАЦИЮ СМ. В РУКОВОДСТВЕ ПО ЭКСПЛУАТАЦИИ.) NOTE: (УКАЗАНИЕ:) THE CAUSE MAY BE THE TYRE PRESSURE SETTING. (ПРИЧИНОЙ МОЖЕТ БЫТЬ ТАКЖЕ РЕГУЛИРОВКА ДАВЛЕНИЯ В ШИНАХ.) |

|

LOSS OF TYRE PRESSURE REAR RIGHT! (ПОТЕРЯ ДАВЛЕНИЯ В ПРАВОЙ ЗАДНЕЙ ШИНЕ!) |

LOSS OF TYRE PRESSURE (ПОТЕРЯ ДАВЛЕНИЯ В ШИНАХ) STOP THE VEHICLE CAREFULLY. (ОСТАНОВИТЕСЬ) IF TYRES WITH RUNFLAT CHARACTERISTICS (“RSC” SYMBOL) ARE FITTED, IT IS POSSIBLE TO CONTINUE THE JOURNEY AT SPEEDS UP TO 80 KM/H. (ПРИ НАЛИЧИИ ШИН, ДОПУСКАЮЩИХ ДВИЖЕНИЕ В АВАРИЙНОМ РЕЖИМЕ (СИМВОЛ “RSC”), МОЖНО ПРОДОЛЖИТЬ ДВИЖЕНИЕ СО СКОРОСТЬЮ НЕ БОЛЕЕ 80 КМ/Ч.) PLEASE REFER TO THE OWNER’S HANDBOOK FOR IMPORTANT INFORMATION. (ВАЖНУЮ ИНФОРМАЦИЮ СМ. В РУКОВОДСТВЕ ПО ЭКСПЛУАТАЦИИ.) NOTE: (УКАЗАНИЕ:) THE CAUSE MAY BE THE TYRE PRESSURE SETTING. (ПРИЧИНОЙ МОЖЕТ БЫТЬ ТАКЖЕ РЕГУЛИРОВКА ДАВЛЕНИЯ В ШИНАХ.) |

|

LOSS OF TYRE PRESSURE REAR LEFT! (ПОТЕРЯ ДАВЛЕНИЯ В ЛЕВОЙ ЗАДНЕЙ ШИНЕ!) |

LOSS OF TYRE PRESSURE (ПОТЕРЯ ДАВЛЕНИЯ В ШИНАХ) STOP THE VEHICLE CAREFULLY. (ОСТАНОВИТЕСЬ) IF TYRES WITH RUNFLAT CHARACTERISTICS (“RSC” SYMBOL) ARE FITTED, IT IS POSSIBLE TO CONTINUE THE JOURNEY AT SPEEDS UP TO 80 KM/H. (ПРИ НАЛИЧИИ ШИН, ДОПУСКАЮЩИХ ДВИЖЕНИЕ В АВАРИЙНОМ РЕЖИМЕ (СИМВОЛ “RSC”), МОЖНО ПРОДОЛЖИТЬ ДВИЖЕНИЕ СО СКОРОСТЬЮ НЕ БОЛЕЕ 80 КМ/Ч.) PLEASE REFER TO THE OWNER’S HANDBOOK FOR IMPORTANT INFORMATION. (ВАЖНУЮ ИНФОРМАЦИЮ СМ. В РУКОВОДСТВЕ ПО ЭКСПЛУАТАЦИИ.) NOTE: (УКАЗАНИЕ:) THE CAUSE MAY BE THE TYRE PRESSURE SETTING. (ПРИЧИНОЙ МОЖЕТ БЫТЬ ТАКЖЕ РЕГУЛИРОВКА ДАВЛЕНИЯ В ШИНАХ.) |

|

TYRE PRESSURE! (ДАВЛЕНИЕ В ШИНАХ!) CHECK (ПРОВЕРЬТЕ) |

RDC SET THE TYRE PRESSURE AND INITIALISE THE TYRE PRESSURE CONTROL (RDC). (ОТРЕГУЛИРУЙТЕ ДАВЛЕНИЕ В ШИНАХ И ИНИЦИАЛИЗИРУЙТЕ СИСТЕМУ КОНТРОЛЯ ДАВЛЕНИЯ В ШИНАХ (RDC).) FURTHER INFORMATION CAN BE FOUND IN THE OWNER’S HANDBOOK. (ДОПОЛНИТЕЛЬНАЯ ИНФОРМАЦИЯ СОДЕРЖИТСЯ В РУКОВОДСТВЕ ПОЛЬЗОВАТЕЛЯ.) |

|

LOSS OF TYRE PRESSURE FRONT RIGHT! (ПОТЕРЯ ДАВЛЕНИЯ В ПРАВОЙ ПЕРЕДНЕЙ ШИНЕ!) |

LOSS OF TYRE PRESSURE (ПОТЕРЯ ДАВЛЕНИЯ В ШИНАХ) STOP THE VEHICLE CAREFULLY. (ОСТАНОВИТЕСЬ) IF TYRES WITH RUNFLAT CHARACTERISTICS (“RSC” SYMBOL) ARE FITTED, IT IS POSSIBLE TO CONTINUE THE JOURNEY AT SPEEDS UP TO 80 KM/H. (ПРИ НАЛИЧИИ ШИН, ДОПУСКАЮЩИХ ДВИЖЕНИЕ В АВАРИЙНОМ РЕЖИМЕ (СИМВОЛ “RSC”), МОЖНО ПРОДОЛЖИТЬ ДВИЖЕНИЕ СО СКОРОСТЬЮ НЕ БОЛЕЕ 80 КМ/Ч.) PLEASE REFER TO THE OWNER’S HANDBOOK FOR IMPORTANT INFORMATION. (ВАЖНУЮ ИНФОРМАЦИЮ СМ. В РУКОВОДСТВЕ ПО ЭКСПЛУАТАЦИИ.) NOTE: (УКАЗАНИЕ:) THE CAUSE MAY BE THE TYRE PRESSURE SETTING. (ПРИЧИНОЙ МОЖЕТ БЫТЬ ТАКЖЕ РЕГУЛИРОВКА ДАВЛЕНИЯ В ШИНАХ.) |

|

TYRE PRESSURE CONTROL MALFUNCTION! (КОНТРОЛЬ ШИН НЕ РАБОТАЕТ!) |

RDC MALFUNCTION (СИСТЕМА RDC НЕ РАБОТАЕТ) TEMPORARY RADIO MALFUNCTION IN TYRE PRESSURE CONTROL SYSTEM (RDC) FROM OUTSIDE CAUSED BY TV OR RADIO TRANSMITTER. (ВРЕМЕННОЕ НАРУШЕНИЕ В РАБОТЕ RDC ИЗ-ЗА ВНЕШНИХ ПОМЕХ ОТ ТВ- ИЛИ РАДИОСТАНЦИИ.) POSSIBLE TO CONTINUE JOURNEY WITH CAUTION. (ДАЛЬНЕЙШЕЕ ДВИЖЕНИЕ ВОЗМОЖНО) |

|

TYRE PRESSURE CONTROL DEACTIVATED! (СИСТЕМА КОНТРОЛЯ ДАВЛЕНИЯ В ШИНАХ ВЫКЛЮЧЕНА!) |

TYRE PRESSURE CONTROL (СИСТЕМА КОНТРОЛЯ ДАВЛЕНИЯ В ШИНАХ) TYRE PRESSURE CONTROL (RDC) NOT AVAILABLE AS A WHEEL WITHOUT A SENSOR IS FITTED. (ФУНКЦИЯ СИСТЕМЫ КОНТРОЛЯ ДАВЛЕНИЯ В ШИНАХ (RDC) НЕ ВЫПОЛНЯЕТСЯ, ТАК КАК КОЛЕСО УСТАНОВЛЕНО БЕЗ ДАТЧИКА.) POSSIBLE TO CONTINUE JOURNEY WITH CAUTION. (ДАЛЬНЕЙШЕЕ ДВИЖЕНИЕ ВОЗМОЖНО) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

LOSS OF TYRE PRESSURE! (ПОТЕРЯ ДАВЛЕНИЯ В ШИНАХ!) |

LOSS OF TYRE PRESSURE (ПОТЕРЯ ДАВЛЕНИЯ В ШИНАХ) STOP THE VEHICLE CAREFULLY. (ОСТАНОВИТЕСЬ) IF TYRES WITH RUNFLAT CHARACTERISTICS (“RSC” SYMBOL) ARE FITTED, IT IS POSSIBLE TO CONTINUE THE JOURNEY AT SPEEDS UP TO 80 KM/H. (ПРИ НАЛИЧИИ ШИН, ДОПУСКАЮЩИХ ДВИЖЕНИЕ В АВАРИЙНОМ РЕЖИМЕ (СИМВОЛ “RSC”), МОЖНО ПРОДОЛЖИТЬ ДВИЖЕНИЕ СО СКОРОСТЬЮ НЕ БОЛЕЕ 80 КМ/Ч.) PLEASE REFER TO THE OWNER’S HANDBOOK FOR IMPORTANT INFORMATION. (ВАЖНУЮ ИНФОРМАЦИЮ СМ. В РУКОВОДСТВЕ ПО ЭКСПЛУАТАЦИИ.) NOTE: (УКАЗАНИЕ:) THE CAUSE MAY BE THE TYRE PRESSURE SETTING. (ПРИЧИНОЙ МОЖЕТ БЫТЬ ТАКЖЕ РЕГУЛИРОВКА ДАВЛЕНИЯ В ШИНАХ.) |

|

BRAKE LIGHT CONTROL FAILURE! (УПРАВЛЕНИЕ СТОП-СИГНАЛАМИ НЕ РАБОТАЕТ!) |

BRAKE LIGHT FAILED (ОТКАЗ СТОП-СИГНАЛОВ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

TYRE PRESSURE CONTROL FAILED! (ОТКАЗ КОНТРОЛЯ ДАВЛЕНИЯ В ШИНАХ!) |

RDC FAILED (ОТКАЗ RDC) TYRE PRESSURE CONTROL (RDC) NOT AVAILABLE. (КОНТРОЛЬ ДАВЛЕНИЯ В ШИНАХ RDC НЕ РАБОТАЕТ) FLAT TYRES CANNOT BE DETECTED. (ПОВРЕЖДЕНИЕ ШИН И ПАДЕНИЕ ДАВЛЕНИЯ НЕ ОПРЕДЕЛЯЕТСЯ) HAVE THE PROBLEM CHECKED BY THE NEAREST BMW SERVICE. (ОБРАТИТЕСЬ НА БЛИЖАЙШУЮ СТОА BMW) |

|

WASHER FLUID LEVEL LOW! (МАЛО ЖИДКОСТИ В БАЧКЕ СТЕКЛО- ОМЫВАТЕЛЯ!) |

WASHER FLUID (ОМЫВАЮЩАЯ ЖИДКОСТЬ) NOT ENOUGH WASHER FLUID IN RESERVOIR. (НИЗКИЙ УРОВЕНЬ ЖИДКОСТИ В БАЧКЕ СТЕКЛООМЫВАТЕЛЯ) TOP UP AT NEXT OPPORTUNITY, PLEASE REFER TO THE OWNER’S HANDBOOK. (ПРИ ПЕРВОЙ ЖЕ ВОЗМОЖНОСТИ ДОЛЕЙТЕ ЖИДКОСТЬ, СМ. РУКОВОДСТВО) |

|

OUTSIDE TEMPERATURE (ТЕМПЕРАТУРА НАРУЖНОГО ВОЗДУХА) |

|

|

COOLANT LEVEL TOO LOW! (НИЗКИЙ УРОВЕНЬ ОХЛАЖДАЮЩЕЙ ЖИДКОСТИ!) |

COOLANT LEVEL (ОХЛАЖДАЮЩ.ЖИДКОСТЬ) NOT ENOUGH COOLANT. (НИЗКИЙ УРОВЕНЬ) RISK OF ENGINE DAMAGE! (ОПАСНОСТЬ ПОВРЕЖДЕНИЯ ДВИГАТЕЛЯ!) ADD COOLANT AT THE NEXT OPPORTUNITY, PLEASE REFER TO THE OWNER’S HANDBOOK. (ПРИ ПЕРВОЙ ЖЕ ВОЗМОЖНОСТИ ДОЛЕЙТЕ ЖИДКОСТЬ, СМ.РУКОВОДСТВО) CAUTION: RISK OF SCALDING! (ОСТОРОЖНО, ОПАСНОСТЬ ОЖОГА ПАРОМ!) |

|

SET TIME AND DATE (УСТАНОВИТЕ ВРЕМЯ И ДАТУ) |

TIME AND DATE (ВРЕМЯ И ДАТА) BATTERY HAS BEEN DISCONNECTED, TIME AND DATE DISPLAYS NO LONGER CORRECT. (АККУМУЛЯТОР БЫЛ ОТСОЕДИНЕН. ПОКАЗАНИЯ ВРЕМЕНИ И ДАТЫ НЕ СООТВЕТСТВУЮТ ДЕЙСТВИТЕЛЬНОСТИ) RESET, PLEASE REFER TO THE OWNER’S HANDBOOK. (УСТАНОВИТЕ ВРЕМЯ И ДАТУ, СМ. РУКОВОДСТВО) |

- Новичок

- Сообщения: 46

- Зарегистрирован: Пн авг 13, 2012 23:52

- Автомобиль: Zafira, 1.8

- Откуда: Санкт Петербург

Что это за сообщение: Parking Light ?

Сообщение

urus_vp » Вт янв 03, 2017 19:38

Машина 2012, Зафира Б (Zafira B)…

Недавно, утром, загорелось и провисело полдня сообщение, которого ниразу не видел за 4е года владения машиной, брал в салоне.

Пытался повторить включая парковочные огни, ни как..

Официалы ро телефону разошлись во мнениях… Проблемы со стояночным тормозом, проблемы с электрикой в целом, и т.п.

Что это могло быть? Надо ли бояться?

-

- Завсегдатай

- Сообщения: 236

- Зарегистрирован: Сб дек 29, 2012 22:36

- Автомобиль: Zafira B, MTA 1.8

- Откуда: Железнодорожный — Щёлково

- Благодарил (а): 24 раза

- Поблагодарили: 69 раз

Re: Что это за сообщение: Parking Light ?

Сообщение

Grekmsk » Вт янв 03, 2017 20:26

с Opel Astra машинки

Оказалось, перегорел передний правый габарит (с одновременно включенным ближним светом я даже не увидел сначала, что он не горит). Завтра куплю лампочку W5W 12V5W и попробую поменять самостоятельно…

Проверьте, мож и у вас так же?

Вот еще:

О! вроде теперь все ясно. У приятеля такая же хрень была. Лампа горит а БК пишет такую ошибку. Лампа может гореть, но на последнем издыхании. Сопротивление меняется и это дает БК инф-цию, что лампу пора менять.

Там не диод, обычная лампочка. Сегодня заменю, если куплю.

_________________

Игорь, ZAFIRA B Family (II), 2012г., Z1.8XER (140 л.с.) MTA5AS, Asteroid Grey, клубные рамки, багажник Atera, бокс TerraDrive 480.

ГУ MTCE_LY (Isudar) PX5 4GB/32GB + DSP 9.0

- Старожил

- Сообщения: 482

- Зарегистрирован: Пн авг 04, 2014 11:35

- Автомобиль: Zafira B Z19DTH AT

- Откуда: 31 регион

- Благодарил (а): 21 раз

- Поблагодарили: 44 раза

Re: Что это за сообщение: Parking Light ?

Сообщение

Dotsent » Вт янв 03, 2017 21:25

Именно так.

Увеличение сопротивления цепи лампы габарита. Или сгорела или скоро додохнет.

Какая конкретно лампа показывается на экранчике БК схематично.

- Новичок

- Сообщения: 46

- Зарегистрирован: Пн авг 13, 2012 23:52

- Автомобиль: Zafira, 1.8

- Откуда: Санкт Петербург

Re: Что это за сообщение: Parking Light ?

Сообщение

urus_vp » Вт янв 03, 2017 22:15

Спасибо!

Завтра проверю…